Imagine you’re walking along a beach, watching surfers slip into sleek black wetsuits before diving into chilly waves. That stretchy, insulating material hugging their bodies—resisting water, flexing with movement, yet retaining warmth—is often neoprene textile. But what exactly is neoprene textile beyond just “that wetsuit stuff”? Whether you’re planning to specify neoprene for bags, covers, koozies, or performance gear, understanding the science, trade-offs, and real-world behavior is essential.

Neoprene textile is a flexible, synthetic polychloroprene rubber foam laminated with fabric layers, prized for its insulation, elasticity, water and chemical resistance, and customizable form.

From there, we’ll unfold its types (closed/open cell, CR vs. SBR), key performance metrics, how it stacks up against alternatives, how it’s made into finished goods, and how best to care for it over its lifespan. Later, we’ll also show how you as a buyer can leverage Szoneier’s 18+ years of neoprene R&D and manufacturing expertise to create custom products. Stay with me — by the end you’ll know whether neoprene is right for your application, and how to make sure you get the best quality when placing orders.

Let me tell you about one client. A boutique outdoor gear brand approached Szoneier wanting a hybrid neoprene lunch tote that looked premium but resisted stains, could be embroidered, and still be flexible. We prototyped with a 3-layer neoprene (neoprene + jersey + PU film), tested temperature protection over 24 hours, and iterated. The first sample held iced drinks cool for 12 hours, while the outer shell remained dry. That result turned a skeptical buyer into a long-term partner. Stories like that show neoprene isn’t just a niche material — it can be a differentiator, if you know how to pick your specs carefully.

Now, let’s dig into the layers — types, properties, applications, comparisons, and manufacturing — so when you request a quote from Szoneier, you’ll speak the language of quality.

What Is Neoprene Textile and How Is It Made?

Neoprene textile is constructed by taking a base of polychloroprene rubber (neoprene foam) and laminating one or more fabric layers (nylon, polyester knit, jersey, etc.). The process often includes foaming (expanding via gas or chemical blowing), vulcanization to crosslink polymer chains, and finishing steps like adhesive lamination or coating. The result is a flexible, compressible, resilient composite suitable for insulation, protection, and cushioning in various products.

Neoprene, or polychloroprene rubber, was first developed by DuPont in the 1930s as a synthetic rubber alternative with better chemical stability and temperature tolerance. Over time, the material has been adapted into foam forms and composite textiles. The “textile” version of neoprene typically refers to a sandwich structure: a neoprene core (foam) plus fabric skins for mechanical strength, aesthetics, and bonding surfaces.

1. Foaming & Core Creation

This is where raw chemistry turns into structure. The process starts with chloroprene monomers that are polymerized into polychloroprene latex. This latex is mixed with additives: foaming agents, stabilizers, fillers, curing accelerators, and sometimes color pigments.

Under carefully controlled heat and pressure, the foaming agent decomposes, releasing gas that expands the rubber into millions of microscopic, sealed air bubbles—creating a uniform closed-cell foam. The density, elasticity, and compressibility of the foam depend on how these bubbles form and how tightly they’re packed.

Key controllable parameters during foaming:

| Property | Typical Range | Unit | Influence on Performance |

|---|---|---|---|

| Foam Density | 0.15 – 0.40 | g/cm³ | Higher = firmer and more durable; lower = lighter and more flexible |

| Cell Type | Closed or Open | — | Closed-cell resists water; open-cell is softer and more breathable |

| Bubble Diameter | 0.1 – 0.4 | mm | Smaller cells improve uniformity and mechanical strength |

| Expansion Ratio | 6 – 10x | — | Determines foam softness and thickness |

| Shore Hardness | 5 – 40 | Shore 00 | Lower = softer and more flexible; higher = firmer |

During this stage, temperature and pressure control are critical. A small variance (even ±3°C) can cause uneven expansion or internal voids. Factories with in-line monitoring and precision temperature calibration achieve more consistent foam blocks—vital for products like wetsuits and protective covers where uniform insulation is required.

2. Vulcanization / Curing

Once foamed, neoprene sheets undergo vulcanization, a process that chemically stabilizes the material by forming crosslinks between polymer chains. Traditionally, sulfur or metal oxides are used as curing agents. This step is what transforms the soft, unstable foam into an elastic yet shape-retaining sponge.

During vulcanization:

- The foam is heated to 160–170°C under pressure.

- Crosslinks between chloroprene chains prevent melting or collapse under stress.

- Elasticity, compression set, and temperature tolerance are “locked in.”

| Test Metric | Typical Value | Test Standard | Meaning for Buyers |

|---|---|---|---|

| Tensile Strength | 2.0 – 5.0 MPa | ASTM D412 | Resistance to stretching under load |

| Elongation at Break | 150 – 300% | ASTM D412 | How far it can stretch before tearing |

| Compression Set (22h @70°C) | <10% | ASTM D395 | Ability to return to shape after compression |

| Operating Temp. Range | -30°C to +100°C | — | Useful for both cold and hot applications |

The degree of crosslinking determines whether neoprene feels “springy” or “stiff.” Insufficient curing leads to poor rebound and aging; excessive curing makes it brittle. Experienced producers, like Szoneier, often calibrate vulcanization profiles to specific applications—so a 3 mm bag foam will feel firm enough to stand, while a 3 mm wetsuit panel will stretch smoothly with the body.

3. Lamination / Fabric Bonding

Raw neoprene foam on its own is fragile—it tears easily and has a rubbery surface that can be sticky or tacky. That’s why almost all commercial neoprene textiles are laminated with one or more fabric layers.

Common Facing Fabrics:

- Nylon or Polyester Knit: Durable, abrasion-resistant, easy to print on.

- Lycra / Spandex: High elasticity and smooth finish for close-fitting products.

- Tricot or Jersey Knit: Soft, comfortable, ideal for wearable applications.

- Velvet or PU Film: Used for premium or decorative surfaces.

The lamination process typically uses heat and adhesive bonding under a controlled press. High-quality adhesives—often solvent-free PU systems—are critical for strong and flexible bonding without adding stiffness.

| Lamination Type | Fabric Faces | Thickness Range | Common Uses |

|---|---|---|---|

| Single Face | 1-side fabric + 1-side bare neoprene | 1–5 mm | Bottle covers, inner padding |

| Double Face | 2-side laminated | 2–7 mm | Bags, laptop sleeves, wetsuits |

| Film Laminated | 2-side + PU or TPU film | 2–4 mm | Waterproof bags, industrial covers |

A proper lamination setup controls pressure (2–5 kg/cm²) and temperature (100–130°C) for uniform bonding. Subpar lamination results in delamination—a major failure mode where fabric peels off during bending or washing.

In Szoneier’s factories, lamination lines include infrared heating tunnels and precision rollers that ensure consistent adhesive spread and temperature gradients. Peel strength is routinely tested to exceed 2.0 N/cm, which is well above general market standards.

4. Finishing & Quality Control

After lamination, sheets enter the finishing stage—where precision and presentation converge. Edges are trimmed, thickness calibrated, and any surface defects removed. Depending on end-use, additional finishes can be added:

- PU or PVC Coating: Adds water, stain, or chemical resistance.

- Embossing: Creates texture (e.g., carbon fiber, honeycomb).

- Color Dyeing or Printing: For aesthetic or branding effects.

- Fire Retardant Treatment: For industrial or safety applications.

Quality control is non-negotiable in neoprene production. Factories measure and record multiple data points per batch:

| Test Item | Standard Value | Purpose |

|---|---|---|

| Thickness Tolerance | ±0.2 mm | Ensures uniform cushioning and assembly fit |

| Density Uniformity | ±5% variation | Prevents uneven compression or color tone |

| Peel Strength | ≥2.0 N/cm | Ensures lamination durability |

| Visual Inspection | No bubbles, no voids | Confirms aesthetic quality |

| Odor / VOC Emission | < 0.5 mg/m³ | Confirms eco-friendly adhesive usage |

Some advanced facilities use CCD scanners to detect micro-bubbles or dark spots invisible to the naked eye. Every lot is tagged with batch numbers for traceability—a standard practice when exporting to markets with strict compliance (EU, Japan, U.S.).

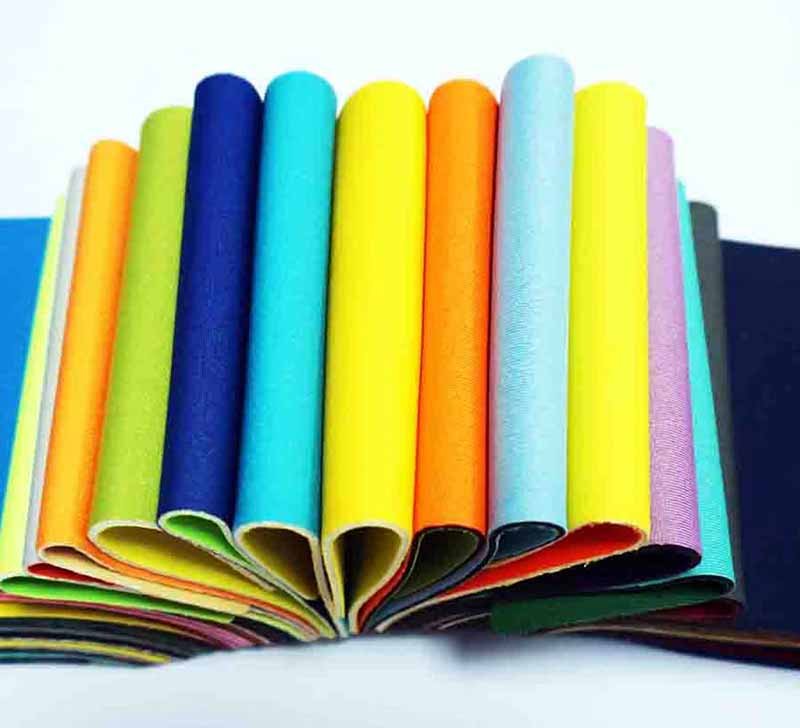

Which Types of Neoprene Fabrics Exist?

The term neoprene fabric doesn’t refer to a single material—it’s a family of engineered rubbers and textiles combined through different formulations, structures, and laminations. Depending on how it’s made, a neoprene fabric can feel plush and breathable like a yoga sleeve, or dense and protective like a laptop case. Manufacturers such as Szoneier, with over 18 years of neoprene R&D, often fine-tune these variations to balance insulation, elasticity, cost, and durability for each client.

There are several major types of neoprene fabrics, categorized by base polymer (CR vs. SBR), cell structure (closed vs. open), and lamination style (single-face, double-face, coated, or composite). Each combination defines the foam’s flexibility, density, waterproofing, and cost—helping designers choose the right material for each product line.

A. Base Polymer: CR vs. SBR / Blends

Every neoprene starts with a base polymer that dictates its chemical and mechanical backbone.

- CR (Chloroprene Rubber): This is the original “neoprene” developed by DuPont. It exhibits superior ozone resistance, UV stability, and temperature resilience (–40 °C ~ 120 °C). It also maintains elasticity longer under compression, making it ideal for performance gear and industrial use.

- SBR (Styrene-Butadiene Rubber): A synthetic rubber substitute that reduces cost but sacrifices some heat and weather resistance. It remains flexible yet slightly more prone to water absorption and aging.

- CR/SBR Blends: A balanced formula (commonly 70–80 % CR + 20–30 % SBR) lowers cost while preserving premium properties. Many mid-tier neoprene bags, braces, and koozies use this formulation.

| Type | Density (g/cm³) | Tensile Strength (MPa) | Temp. Range (°C) | Aging Resistance | Relative Cost | Typical Use |

|---|---|---|---|---|---|---|

| Pure CR | 0.25–0.45 | 3.5–6.0 | –40 ~ 120 | Excellent | $$$ | Wetsuits, safety gear, industrial seals |

| CR/SBR Blend | 0.22–0.40 | 2.5–4.5 | –30 ~ 100 | Good | $$ | Bags, sleeves, covers |

| SBR | 0.18–0.35 | 2.0–3.0 | –20 ~ 80 | Fair | $ | Promotional items, koozies, padding |

In global sourcing, 90 % of “neoprene” sold online is actually blended or SBR-based, not pure CR. That doesn’t mean it’s poor quality—but for critical applications (e.g., diving suits, automotive insulation) you should confirm the CR ratio through material test reports (FTIR or DSC analysis).

B. Cell Structure: Closed-Cell vs. Open-Cell

The foam’s cell structure determines how it behaves under compression, absorbs water, and insulates heat.

- Closed-Cell Neoprene Each air bubble is sealed, creating a waterproof and buoyant material. This structure provides thermal insulation, shock absorption, and resistance to mildew or bacterial growth. It’s heavier but long-lasting—perfect for wetsuits, cases, and outdoor covers.

- Open-Cell Neoprene The cells interconnect, giving a sponge-like softness and high compressibility. It conforms easily to curves, offering comfort and ventilation, but it can absorb water unless coated or laminated. Common in padding, orthopedic supports, or sound-dampening layers.

| Feature | Closed-Cell Foam | Open-Cell Foam |

|---|---|---|

| Structure | Sealed air bubbles | Interconnected pores |

| Water Absorption | < 5 % | > 30 % (unless sealed) |

| Thermal Insulation | Excellent | Moderate |

| Compressibility | Medium | High |

| Rebound Recovery | Strong | Moderate |

| Breathability | Low | High |

| Typical Use | Wetsuits, bags, protective sleeves | Padding, upholstery, sports braces |

In high-end laminations, hybrid structures are created by controlling the gas pressure during foaming—partially open cells near the surface for comfort, and closed cells in the core for insulation. Szoneier’s engineers often adjust the expansion ratio (6–10×) to reach the right compromise between flexibility and buoyancy.

C. Lamination Styles

Lamination transforms raw foam into a usable fabric by bonding one or two textile layers to it. This step not only adds tensile strength but also defines surface feel, printability, and overall durability.

1. Single-Face Laminate

Neoprene with fabric on one side and bare foam on the other.

- Pros: Light, flexible, economical.

- Cons: Exposed rubber side may oxidize or stick over time.

- Applications: Inner layers, koozies, low-cost covers.

2. Double-Face Laminate

Fabric on both sides; the most widely used construction.

- Pros: Balanced strength, no exposed foam, smooth handling.

- Cons: Slightly heavier, higher material cost.

- Applications: Bags, sleeves, wetsuits, straps.

3. Specialty Surfaces

- Nylon / Polyester Knit: Durable, scuff-resistant, easy to print or dye.

- Jersey Knit: Soft, flexible, great for wearable products.

- Lycra / Spandex: High stretch, perfect for close-fit garments.

- Tricot: Warp-knit, fine texture, luxury applications.

- PU Film: Smooth, waterproof finish for industrial or fashion goods.

| Lamination Type | Face Fabric | Typical Thickness | Peel Strength (N/cm) | Surface Features | Common Use |

|---|---|---|---|---|---|

| Single Face | Nylon | 1–3 mm | ≥ 1.5 | Light, flexible | Koozies, inner pads |

| Double Face | Polyester Knit | 2–7 mm | ≥ 2.0 | Tough, balanced | Bags, sleeves |

| Lycra Faced | Lycra/Spandex | 2–5 mm | ≥ 1.8 | Smooth, stretchy | Wetsuits, braces |

| Film Laminated | PU / TPU Film | 2–4 mm | ≥ 2.5 | Glossy, waterproof | Covers, industrial gear |

Lamination quality is typically verified by peel-strength testing (ASTM D903). A professional producer will record average values per batch to guarantee that adhesive bonds remain stable after washing or stretching.

D. Custom Additions & Surface Treatments

Beyond base lamination, manufacturers frequently enhance neoprene with coatings, prints, or additives that tailor performance for specialized markets.

- PU (Polyurethane) Coating: Adds stain and oil resistance while improving colorfastness.

- PU or TPU Film Lamination: A thin, transparent barrier layer increasing waterproof rating (≥ 5 000 mm H₂O) for outdoor or marine applications.

- Embossed Surface Texture: Aesthetic differentiation—carbon fiber, diamond, honeycomb, or leather grain effects.

- Flame-Retardant Formulation: Meets UL 94 V-0 or FMVSS 302 standards for safety gear or automotive interiors.

- Antibacterial / Odor-Resistant Treatment: Popular in sports accessories and medical supports.

| Enhancement | Function | Added Cost Impact | Common Industries |

|---|---|---|---|

| PU Coating | Water & oil repellence | +5–8 % | Outdoor gear, bags |

| TPU Film | Waterproofing, durability | +10–15 % | Marine, protective covers |

| Embossing | Visual texture | +3–5 % | Fashion, luggage |

| FR Additives | Fire resistance | +8–12 % | Safety, automotive |

| Antibacterial | Hygiene, odor control | +5 % | Sportswear, medical |

Each additional process requires compatibility testing; incorrect temperature or adhesive choice can cause delamination or surface whitening. Szoneier maintains in-house testing labs capable of 100 h accelerated aging (70 °C × 95 % RH) to ensure coatings maintain adhesion and elasticity.

E. Trade-Offs and Material Selection Logic

Designers and buyers rarely pick neoprene type by intuition—it’s a matrix of performance versus economics. Below is a simplified selection guide summarizing how each factor influences decision-making.

| Application | Recommended Base | Structure | Lamination | Coatings | Cost Level | Key Performance Goal |

|---|---|---|---|---|---|---|

| Wetsuit | CR | Closed-cell | Double Lycra | None | High | Stretch & warmth |

| Laptop Sleeve | CR/SBR Blend | Closed-cell | Double Polyester | PU Coating | Medium | Shock absorption |

| Sports Brace | CR | Semi-open | Nylon + Jersey | Antibacterial | Medium-High | Compression & comfort |

| Promotional Koozie | SBR | Closed-cell | Single Face Jersey | None | Low | Flexibility, printability |

| Industrial Pad | CR | Closed-cell | Nylon | FR Additives | High | Durability, heat resistance |

In general, each added layer increases cost by 5–10 % and weight by 8–12 %, so efficiency lies in specifying only the features truly required by your end market.

A neoprene buyer should always ask suppliers for:

- Base polymer composition report (CR %, SBR %)

- Foam density and hardness data

- Peel strength and compression set test results

- Coating or additive confirmation (e.g., REACH, OEKO-TEX)

Reputable manufacturers like Szoneier provide comprehensive technical datasheets for every neoprene batch, giving transparency on physical and mechanical parameters. This enables overseas buyers to make sourcing decisions confidently without overpaying for unnecessary specifications.

What Key Properties Define Neoprene Performance?

Neoprene’s performance is primarily defined by thermal insulation (R-value), elasticity / stretch recovery, compression set, tensile and tear strength, peel adhesion, and resistance to water, UV, chemicals, and aging. These metrics differentiate a mediocre batch from a product-grade textile, and shape how well your end product will perform under real use.

To truly evaluate neoprene, you must understand how lab numbers translate into real-world behavior. Let’s examine the key properties in context, and how they interact.

Thermal Insulation

- One of neoprene’s chief selling points is its insulation. Closed-cell foam traps gas bubbles, which impede heat transfer.

- The insulation effect is often measured via thermal conductivity (W/m·K) or resistance (R-value). Lower conductivity = better insulation.

- For example, a neoprene sheet with conductivity of 0.035 W/m·K is significantly better than a dense rubber sheet at 0.12.

- When designing a food cooler sleeve or protective case, a thicker foam or lower density (more voids) could improve cooling/hot retention.

Elasticity & Stretch Recovery

- Neoprene must stretch (for form-fitting covers or flexible sleeves) and return to shape.

- The stretch may be 100 % or more depending on thickness and face fabric.

- The “compression set” is a related metric: if you compress it 50 % for 22 hours at elevated temperature, what percentage does it fail to recover? A low compression set (e.g., < 10 %) is better.

- For dynamic applications (sleeves, wetsuits), you want high fatigue resistance over repeated cycles.

Tensile / Tear / Tear-Propagation Strength

- Because neoprene is often cut and stressed at seams, its tear strength and how a crack propagates matter.

- A high tear strength base ensures that small cuts won’t propagate and fail the piece.

- Fabric lamination contributes: a tough outer knit can prevent abrasion and tear from the surface.

Peel / Adhesion Strength

- The bond between fabric and foam needs to survive bending, washing, and temperature changes.

- Peel strength is typically measured in N/cm. You might see specs like “peel > 2.0 N/cm for 180° peel over 15 mm width.”

- Delamination is a frequent cause of failure in cheap neoprene products.

Resistance to Water, Chemical & UV Aging

- Closed-cell neoprene resists water absorption; open-cell tends to soak moisture unless coated.

- The material must resist chlorine (for pool gear), oils, solvents, and salt water.

- UV exposure and temperature cycling can degrade polymer chains, reducing durability.

- Accelerated aging tests (e.g. 70°C / 95% RH for 500 hrs) are common to validate long-term life.

Density, Weight & Compression Behavior

- Lower density foam (more voids) is lighter and has better insulating performance, but may compress too easily.

- Higher density gives mechanical sturdiness, but less insulation per thickness.

- Balancing density vs. thickness is key: e.g. to meet a 3 mm spec but preserve bounce and comfort.

Additional Specialty Properties

- Sound dampening / vibration absorption (for industrial gear)

- Flame retardancy (for safety gear)

- Electric insulation (dielectric strength)

- Custom color / pigment stability

When specifying neoprene for your product, it’s not enough to ask for “good neoprene.” Instead, request concrete numbers: density, peel strength, compression set, tear strength, etc. Compare suppliers on those terms, not just price per square meter.

Which Applications Are Best Suited to Neoprene?

Neoprene’s insulation, flexibility, cushioning, and water resistance make it ideal for bags/sleeves, drink koozies, covers / protective cases, wetsuits / dive apparel, support braces / sleeves, and industrial uses like vibration padding or gaskets. Each application leans on different performance attributes (e.g. thickness, adhesion, fabric lamination) — the trick is matching specs to use-case, not using “one size fits all.”

Let’s break down the main use scenarios and how you should approach specs for each:

1. Bags, Laptop Sleeves & Cases

These products demand a balance of cushion, structure, and aesthetics. Buyers typically expect:

- Medium-density neoprene (~0.20–0.30 g/cm³)

- Double-face lamination (knit or jersey on both sides)

- Good peel strength so that stresses at seams don’t delaminate

- Outer abrasion-resistant knit (nylon or polyester)

- Aesthetic treatments (embroidery, printed surfaces, embossing)

- Light water resistance (a splash-proof coating, optionally)

In a laptop sleeve, for example, 3 mm neoprene may be used in panels, but reinforced edges and stitching or overlock binding is crucial to prevent tear propagation.

2. Drink Koozies / Bottle / Can Covers

These small sleeves require minimal thickness, easy printing, and flexibility. Product spec priorities often include:

- 1–2 mm thickness

- Single-face laminate (neoprene + face knit)

- Excellent printing adhesion (sublimation or screen)

- Low compression set (so it springs back after gripping bottles)

- Light density to reduce cost

Because koozies are lightweight, cost per unit is more sensitive; but if the peel strength is too low, the print or logo will peel off after a few uses.

3. Protective Covers / Equipment Cases

For covers (like lens covers, camera cases, bike frame covers), you want:

- Closed-cell foam to block moisture

- Moderate thickness (2–5 mm)

- Strong outer fabric knit and abrasion resistance

- Bonding strength between layers

- UV / aging resistance

Because these often live outdoors, wear and tear, temperature swings, and durability are high priorities.

4. Wetsuits & Aquatic Apparel

This is perhaps the most iconic use of neoprene. Key demands include:

- Ultrathin (1–5 mm) but flexible neoprene

- High stretch lycra / nylon facings

- Flatlock stitching, blindstitch, or taped seams for sealing

- Seam sealing (liquid tape, glue, or radio frequency welded seams)

- Quick-dry inner linings

- Low water absorption, rugged fatigue life

Because wetsuits are performance items for athletes, small deficiencies in stretch, compression set, or UV aging can break the user’s confidence quickly.

5. Support Braces, Sleeves & Medical / Sports Gear

Neoprene offers compression, flexibility, warmth, and cushioning — ideal for knee sleeves, elbow braces, back belts. Spec needs include:

- Medium thickness and density

- High elasticity with reliable stretch recovery

- Soft jersey facings for comfort

- Good breathability if used for long periods

- Reinforced seams

For orthopedic or therapeutic gear, certifications or biocompatibility issues sometimes matter; thus, the factory should support material traceability and compliance.

6. Industrial, Acoustic & Gasket Uses

Beyond consumer goods, neoprene finds use in:

- Vibration damping pads and mounts

- Gaskets and seals

- Acoustic insulation panels

- Protective padding for machinery

Here, mechanical properties, chemical resistance, durability, hardness, and consistency are critical. The foam must survive cyclic loads, temperature swings, or exposure to oils/solvents.

How Does Neoprene Compare with Alternatives?

While neoprene offers excellent insulation, water resistance, elasticity, and durability, alternatives like EVA foam, TPE, NBR sponge, and spacer mesh often trade off a subset of those qualities for cost, lighter weight, or different feel. The right material depends on which performance axes matter most (e.g. cost per unit, flexibility, printability, durability).

Let’s assess how neoprene stacks up against common competitors, including pros, cons, and use-case guidance.

EVA (Ethylene Vinyl Acetate) Foam

- Pros: Very low cost, lightweight, soft, good cushioning, easy to die-cut or foam-cut.

- Cons: Less elastic recovery, more prone to permanent deformation (higher compression set), weaker chemical/UV resistance, lower adhesion for fabrics/prints.

- Better for: Low-cost inserts, foam padding, non-structural applications or disposables.

- Not ideal for: High-stress or long-lifetime covers, where delamination or breakage is risk.

TPE (Thermoplastic Elastomer)

- Pros: Recyclable, often easier to process, good flexibility, lower odor, sometimes lower VOCs.

- Cons: Less insulating at thin gauges, may have weaker tear or fatigue life in some forms.

- Better for: Eco-focused products, low-thickness profiles, parts requiring recyclability.

- Not ideal for: Heavy insulation or extreme durability demands (unless premium TPE blends).

NBR (Nitrile Rubber) Sponge

- Pros: Good oil and chemical resistance (especially to fuels, oils), decent flexibility.

- Cons: Generally poorer weather/UV resistance, less stretch recovery, may degrade faster in sunlight.

- Better for: Industrial gaskets, protective padding where oil/chemical resistance are critical.

- Not ideal for: Long outdoor life use in sun and moisture, or for aesthetic product surfaces.

Spacer Mesh / Foam Mesh

- Pros: Very breathable, light, cushioning, cheap.

- Cons: Lacks water sealing, poor thermal insulation, weaker durability.

- Better for: Backing layers, interior padding in shoes or bags, where ventilation matters more than waterproofing.

- Not ideal for: Covers, insulation, or barrier applications.

Composite Hybrids & Laminates

Some products mix neoprene with other materials (thin PU film, closed-cell EVA layers, foam cores) to get “best of both worlds.” This is where a strong manufacturing partner helps: properly bonding dissimilar materials is nontrivial.

Practical Comparison Table

| Material | Insulation | Stretch / Recovery | Water Resistance | Durability / UV | Cost Relative | Best Use Cases |

|---|---|---|---|---|---|---|

| Neoprene | High | Good | Excellent (if closed-cell) | Excellent | Medium–High | Covers, sleeves, wetsuits, padding |

| EVA foam | Medium | Moderate | Poor | Moderate | Low | Foam inserts, cushioning, mats |

| TPE | Medium | Good | Moderate | Good | Medium | Reusable parts, eco-focused products |

| NBR sponge | Low–Medium | Moderate | Good (oil) | Fair | Medium | Industrial pads, seals, gaskets |

| Spacer mesh | Low | Excellent (flexible) | Poor | Moderate | Low | Padding, breathable layers, vents |

In many real-world cases, the decision isn’t purely “neoprene or nothing.” It’s about which trade-offs you accept. A consumer-grade lunch tote might use a hybrid foam to cut cost while preserving comfort. But for performance gear, the margin for failure is small. That’s why partnering with a factory that deeply understands foam behavior (like Szoneier) becomes a competitive advantage.

How Are Neoprene Products Manufactured and Finished?

Neoprene products are manufactured via cutting (die-cut, CNC, laser), sewing (flatlock, blindstitch), bonding (adhesive glues, RF welding), edge finishing (binding, folding, tape), and printing (screen printing, sublimation, embossing). Quality control focuses on seam strength, peel strength, dimensional tolerances, and visual defects.

Turning laminated neoprene sheets into final consumer items is a nuanced process — slight missteps lead to delamination, weak seams, or cosmetic defects. Let’s walk through each stage, with tips and pitfalls.

1. Cutting

- Die-cutting: Common for flat parts (koozies, inserts). Precise and efficient for high volumes.

- CNC / Digital Knife Cutting: Best for more complex shapes or lower volume runs; allows rapid iteration.

- Laser Cutting: Useful for precision edges, though care must be taken to avoid burning or edge cracking.

Cutting must respect the fabric grain (if lamination facings have directional stretch) and allow for seam allowances. Also, waste yield should be optimized — a good manufacturer nests parts to reduce scrap.

2. Sewing / Stitching Methods

- Flatlock stitching: Preferred for applications where seam comfort and flexibility matter (wetsuits, sleeves). The layers are butted together and locked — often less bulky.

- Blindstitch / Blind hemming: For seams that should not leak (common in water gear).

- Overlock / Serger stitching: For joining pieces in bag or cover construction, often with edge binding to avoid fraying.

- Glue + stitching hybrid: In many cases, glue is applied first to bond layers, then stitching reinforces the seam.

Stitch density (stitches per inch), thread type (nylon, polyester, bonded thread), and back-stitching/neural reinforcing are all critical. A weak seam or low thread count can cause rupture under real-world loads.

3. Bonding & Adhesive Techniques

- Some seams or joints (especially in thin, intricate parts) are better handled via adhesives.

- Neoprene adhesives typically are solvent-based or contact adhesives that cure under pressure and time.

- In advanced setups, RF (radio frequency) welding or heat welding may join layers without thread holes — ideal for waterproof or seamless parts.

- The selection of adhesive (compatibility with core polymer, fabric, curing conditions, VOCs) demands experience — a wrong glue can degrade foam or delaminate.

4. Edge Finishing & Binding

- After cutting and seam assembly, edges often need reinforcement: binding tape (nylon/polyester), fold-over edges, or overlock edging.

- Edge binding improves aesthetics, protects foam edges, and adds seam strength.

- In thin materials, the edge binding must be carefully selected so it doesn’t bulk up or distort.

5. Surface Decoration & Printing

- Screen printing: Common for logos, text, or graphics. Requires that inks adhere well to the fabric facing and survive flexing / washing.

- Sublimation printing (dye-sublimation): Works well when the facing is polyester-based and can accept the dye. Offers vibrant, durable graphics.

- Embossing / debossing / heat transfer vinyl: Possible for decorative logos, but limited by the flexibility of the substrate.

- Lamination of film or PU prints: sometimes decorative films are laminated onto the surface for a special effect (matte, gloss, metallic).

Ink and printing adhesion are common failure points in neoprene goods, especially small-batch or low-cost runs. Fabrics must be pre-treated, inks selected properly, and post-cure / annealing handled correctly.

6. Quality Control & Testing

- Peel test (fabric-to-foam adhesion): random samples are peeled to verify bond strength.

- Dimensional tolerance: verify thickness, width, length tolerances within spec.

- Seam strength test: samples are pulled to break point to test seam quality.

- Visual inspection: look for delamination, voids, bubbles, discoloration, edge frays.

- Aging / cyclic stress test: simulate flexing, UV exposure, humidity cycles to see if the finished product degrades prematurely.

- Water absorption / soak test (for covers, wet gear) to measure changes in mass or expansion.

A high-quality factory will document results, reject batches with anomalies, and provide test reports to buyers. As a buyer, insist on random batch sampling and test reports.

7. Scale & Cost Considerations

- Volume matters: tooling costs (dies, molds, cutting masks) amortize better at higher volumes.

- Labor skill: Neoprene sewing, bonding, and finishing require experience — mistakes in glue curing, over-pressing, or stitching alignment degrade yield.

- Material waste: optimizing layout, reducing scraps, and reusing leftover foam improves margins.

- Logistics: foam sheets are bulky to ship; factories often optimize cutting closer to final region to reduce freight costs.

One of Szoneier’s strengths is combining 18+ years of R&D with on-the-ground cutting, sewing, and finishing expertise to ensure your custom product isn’t just spec’d well — it’s produced consistently at scale, with quality you can verify.

How to Care for and Maintain Neoprene Textile?

To prolong neoprene’s life, rinse with fresh water after use, avoid harsh detergents or bleach, air dry flat in shade, do not wring or twist, store flat or rolled (not creased), and keep away from direct heat or sunlight. This helps preserve lamination, maintain flexibility, and minimize delamination or cracking.

Neoprene is remarkably forgiving compared to many synthetic fabrics—but poor care adds wear and failure. Below are best practices, diagnostic tips, and trouble-shooting guidance.

Basic Cleaning

- Rinse with cool, fresh water soon after use (especially after contact with salt, chlorine, or sweat).

- Use a mild pH-neutral detergent (no bleach, no strong alkali) if deeper cleaning is needed. Avoid solvents or abrasive scrubbing.

- Use a soft sponge or cloth — avoid stiff brushes that might abrade face fabrics.

Drying

- Always air dry flat or hang in gentle curves; do not wring, twist, or hang rigidly.

- Avoid heat sources (radiators, blow dryers, direct sun) which can degrade adhesives and foam.

- Ensure both sides dry fully to prevent trapped moisture which can lead to mold or delamination.

Storage

- Store flat (if possible) or loosely rolled (not tight) to avoid creasing the foam.

- Keep in shaded, dry areas — UV light and high heat accelerate aging.

- If you must fold, do so gently, and avoid creating sharp creases that might crack the foam.

Spot Repair / Patch Care

- For small tears or delamination, use a compatible neoprene adhesive or repair tape (thin neoprene-backed fabric tape).

- Clean and dry the area first, apply adhesive sparingly, clamp until cured.

- Avoid over-layering with thick patches which may change the flex properties.

Avoiding Damage

- Never use bleach, fabric softeners, or strong solvents (e.g. acetone) — they can degrade rubber bonds.

- Avoid stretching the neoprene to its absolute limit frequently — fatigue sets in faster.

- Keep away from sharp objects and abrasive surfaces to reduce micro-tears or abrasion.

Inspect Periodically

- Every few months (or before shipping, for product inventory), inspect seams for starting delamination.

- Check the foam surface for micro crack lines or crazing.

- If signs appear, retire or rework the item; delayed repair often leads to bigger problems.

With proper care, a well-built neoprene product can last many years. That’s part of what you pay for when you source high-quality material and workmanship — extendable product life that satisfies end users.

Conclusion

You’ve now seen in depth:

- What neoprene textile is, from polymer to laminated composite

- Which types exist, and how base polymer, cell structure, and lamination influence performance

- What core properties matter, and how they translate into usable product behavior

- Which end applications make sense for neoprene — and how specs shift among them

- How neoprene stacks up against alternatives like EVA, TPE, NBR, and spacer mesh

- How real neoprene goods are manufactured, from cutting to finishing, bonding, and testing

- How to care for neoprene to preserve performance and durability

But this is not just theory — as a serious buyer you want reliable supply, contract certainty, and proof of quality. That’s where Szoneier can deliver value: with 18+ years of neoprene R&D and integrated manufacturing, we can help you:

- Choose the optimal foam density, lamination scheme, and face fabric

- Prototype rapidly (quick sample & iteration)

- Provide lab test reports (peel, compression, aging)

- Support printing, binding, custom logo work, and finishing

- Offer low MOQ, free design support, and fast lead times

If you have a project in mind — whether it’s a neoprene bag, koozie, wetsuit, protective cover, or something else — I invite you to contact Szoneier today. Share your ideal thickness, usage environment, aesthetic preferences, expected volumes, and let us help you select the right materials, produce prototypes, validate performance, and launch a high-quality product.

Let’s build something that stands out — and lasts.