Imagine a material that can keep you warm in freezing water, protect your electronics from bumps, and even insulate construction joints in skyscrapers. That material is neoprene. Born from the quest for a synthetic alternative to natural rubber, neoprene revolutionized industries by combining flexibility, durability, and resistance in a single package. Midway through this introduction, let’s cut straight to the chase: neoprene is a synthetic rubber (polychloroprene) made through emulsion polymerization that offers unmatched water resistance, thermal insulation, chemical stability, and elasticity, making it a go-to choice for products ranging from bags to wetsuits. Ever wondered how one material can fit such varied roles? Keep reading—by the end, you’ll see how neoprene’s journey from a lab chemical to a staple in manufacturing started with a story of innovation and need, and how that journey continues at Szoneier today.

Let me share a quick anecdote: in the early 1950s, a group of engineers tested a rubber-like foam on oil rigs, hoping to find a leak-proof seal. What they discovered was a material so adaptable that it could transform into anything from a protective phone sleeve to a custom-branded neoprene koozie for your favorite beverage. And that’s when designers realized neoprene’s potential wasn’t just industrial—it was universal. Now, let’s dive deeper to understand exactly how this versatile miracle works.

What Is Neoprene and How Is It Made?

Neoprene is a synthetic rubber (polychloroprene) produced via emulsion polymerization of chloroprene monomers. This process yields either closed-cell foam or solid sheets, both prized for flexibility, toughness, and resistance to water, oil, and heat.

Understanding the Chemical Nature: Is Neoprene Rubber or Plastic?

Neoprene’s core ingredient is chloroprene, a monomer that undergoes emulsion polymerization—a process where tiny droplets of chloroprene are suspended in water with emulsifiers. When heated and treated with catalysts, these droplets link together to form polychloroprene chains. Unlike natural rubber (polyisoprene), which is harvested from trees, neoprene is totally manmade. Because its molecules form cross-linked networks, neoprene behaves like rubber—stretchy, elastic, and resilient—yet its chemical backbone also displays some “plastic-like” characteristics, such as good shape retention and resistance to many chemicals. That’s why engineers sometimes call it a “rubber-like plastic.”

How Emulsion Polymerization Shapes Neoprene’s Form

- Chloroprene Emulsion Stage

- Chloroprene monomers are mixed with water, emulsifiers, and initiators.

- Small droplets of chloroprene form, stabilized by emulsifiers (e.g., sodium lauryl sulfate).

- The reaction mixture is maintained at a specific temperature (around 5°C–10°C) to control droplet size and polymerization rate.

- Polymerization and Coagulation

- Initiators (often peroxides) trigger chain reactions, forming long polychloroprene chains.

- As polymer chains grow, they coagulate into rubber particles.

- The coagulated rubber is separated from water, washed, and dried to yield raw neoprene.

- Foam vs. Solid Production

- Closed-Cell Foam: To create foam, nitrogen gas or chemical blowing agents are injected during mixing. The gas expands in micro-cells, creating a lightweight, insulating structure.

- Solid Sheets: For solid neoprene, the rubber paste is calendered or extruded into sheets, then vulcanized (heated) to cross-link the polymer chains.

Why This Process Matters for Manufacturers

- Consistent Quality: Emulsion polymerization yields uniform molecular weight distribution, ensuring each batch of neoprene exhibits predictable stretch and recovery.

- Customizable Formulations: By tweaking initiator types, emulsifier concentrations, or polymerization temperature, manufacturers can adjust hardness (durometer), density (foam vs. solid), and elasticity.

- Versatile End-Use: From eyeglass straps to industrial gaskets, this controlled process allows companies like Szoneier to tailor neoprene to fit specific product requirements.

What Properties Make Neoprene So Versatile Compared to Other Materials?

Neoprene stands out due to its unique closed-cell foam structure, excellent water and weather resistance, thermal insulation, high elasticity, and strong chemical stability.

What Is So Special About Neoprene?

Neoprene’s closed-cell foam traps tiny air pockets, acting like an insulating barrier that keeps heat in and water out. It resists UV rays, ozone, and many chemicals (acids, alkalis, oils), making it ideal for both outdoor and industrial uses.

Closed-Cell Structure and Insulation

- Air Pockets as Insulators: Imagine thousands of miniature bubbles—these cells resist heat transfer, so neoprene retains warmth in wetsuits and protects electronics in padded bags.

- Waterproof Barrier: The closed-cell foam resists water penetration, so a neoprene cooler bag can keep drinks cold for hours without leaking.

Chemical and Weather Resistance

- UV and Ozone Stability: Sunlight and ozone cause many rubbers to crack over time. Neoprene’s chemical bonds resist these effects, preserving performance outdoors.

- Oil and Solvent Resistance: Certain oils can degrade natural rubber, but neoprene stays intact when exposed to light oils or solvents—making it useful for automotive seals.

Elasticity and Physical Toughness

- High Stretch, Quick Recovery: Neoprene can stretch up to 200% of its original length and return without permanent deformation. This elasticity reduces tear propagation, so a neoprene laptop sleeve remains snug yet forgiving.

- Abrasion Resistance: The material’s surface resists scuffs, ensuring neoprene gloves or bags maintain appearance even under rugged use.

Is Neoprene a Good Fabric?

When laminated with textiles (e.g., nylon, polyester, spandex), neoprene becomes a “fabric” prized for flexibility, durability, and comfort. It wicks moisture, provides stretch for active wear like wetsuits, and offers enough structure for stylish neoprene bags.

Lamination and Fabric Performance

- Nylon or Polyester Backing: Laminating with nylon adds tensile strength, preventing outright tearing. Polyester backing can improve resistance to pilling and color fading.

- Spandex Blend: Adding spandex enhances stretch and recovery, critical for form-fitting apparel.

Breathability and Comfort Considerations

- Breathability Trade-Off: Pure neoprene foam is not very breathable. By incorporating microporous or mesh-type backing, manufacturers can improve airflow, making garments more comfortable for extended use.

- Skin-Friendly Surfaces: Some neoprene fabrics feature soft, brushed linings to prevent chafing in wetsuits or gloves.

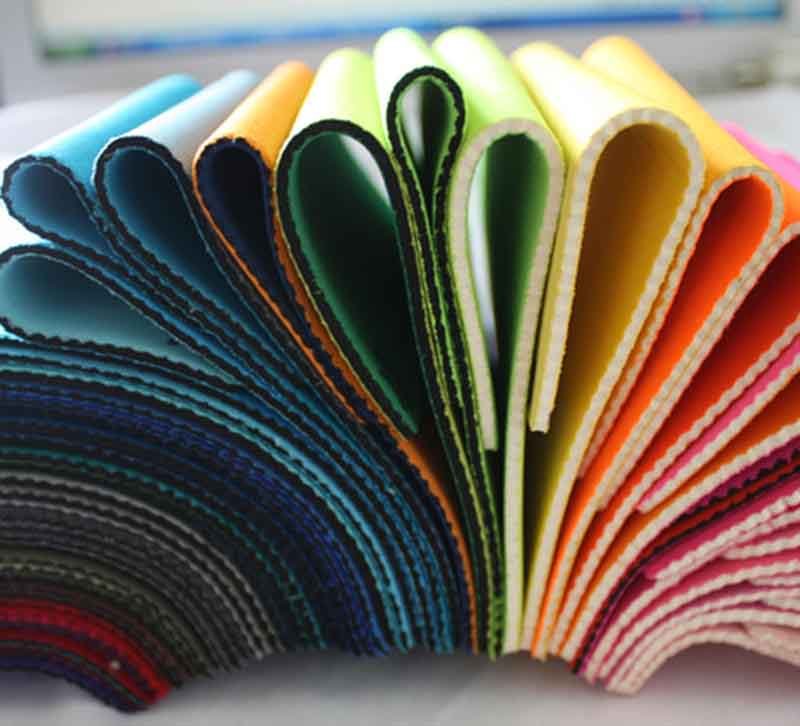

Which Neoprene Types Are Best for Different Applications?

Different neoprene grades—ranging from soft 1 mm foams to dense 7 mm sheets—cater to diverse uses; choose soft-grade for beverage koozies and protective sleeves, and thicker, high-durometer sheets for industrial seals or diving suits.

Neoprene Thickness and Durometer: A Quick Guide

Below is a table summarizing common neoprene thicknesses, typical durometer values, and their most popular applications. You can copy and paste this when choosing materials for prototypes or production:

| Thickness (mm) | Durometer (Shore A) | Typical Application | Properties Emphasized |

|---|---|---|---|

| 1.0–2.0 | 40–50 | Drink koozies, tool grips, thin liners | Lightweight, slight insulation |

| 2.0–3.0 | 50–60 | Neoprene gloves, laptop/tablet sleeves | Moderate insulation, flexibility |

| 3.0–5.0 | 60–70 | Neoprene bags, camera cases, protective pads | Balanced protection & flexibility |

| 5.0–7.0 | 70–90 | Wetsuits, orthopedic braces, heavy-duty seals | Maximum insulation & durability |

Soft-Grade vs. High-Durometer Neoprene

- Soft-Grade Neoprene (40–60 Shore A)

- Feels sponge-like (closed-cell foam).

- Ideal for drink sleeves, shallow-water snorkeling hoods, or lightweight protective cases.

- Easier to die-cut or laser-cut into intricate shapes.

- More compressible, making it suitable for cushioning in bags or coolers.

- High-Durometer Neoprene (70–90 Shore A)

- Denser, tougher, and less compressible.

- Used in diving wetsuits (greater resistance to water compression at depth), industrial gaskets, or heavy-duty gloves.

- Offers more structural support in knee or elbow braces.

Closed-Cell Foams vs. Open-Cell Laminates

- Closed-Cell Foam: Gas-filled cells resist water and provide consistent buoyancy and insulation. Perfect for waterproof cases and buoyant collars.

- Open-Cell or Microcellular Laminates: Allow slight water ingress, which warms against the skin and retains warmth in wetsuits. These foams are often laminated to fabric for improved comfort in apparel.

Examples of Application Selection

- Drink Koozies: Use 2 mm foam; retains coolness, fits snugly, and is cost-effective at low MOQs.

- Camera Cases: 3 mm–4 mm foam with nylon backing; protects against bumps, is washable, and resists dust.

- Wetsuits: 5 mm–7 mm open-cell or microcellular foam laminated to nylon/spandex; balances warmth with mobility.

- Industrial Seals: 5 mm–6 mm solid neoprene (no foam) at 80 Shore A; withstands oil, ozone, and repeated compression.

How Do Neoprene Products Benefit OEM/ODM Manufacturers and Brand Owners?

Neoprene’s adaptability—ranging from customizable thickness and finishes to low MOQ sampling—makes it a compelling choice for OEM/ODM brands seeking speed, quality, and competitive pricing.

Why Neoprene Works for OEM/ODM Workflows

For a brand or manufacturer, neoprene’s production process offers several advantages:

- Low Minimum Order Quantities (MOQs): Many factories, including Szoneier, accept MOQs as low as 500–1,000 pieces for simple neoprene products (e.g., phone sleeves or koozies). This is a game-changer for startups or small brands testing new SKUs.

- Rapid Sampling and Prototyping: Because standard neoprene sheets are pre-manufactured, prototyping usually takes 3–5 days. Once a sample is approved, bulk production of 5,000+ units can often be completed in 15–20 days.

- Custom Branding and Private-Label Options: Neoprene surfaces print exceptionally well. Brands can request all-over sublimation printing, full-color digital prints, or simple screen prints of logos. Szoneier can apply custom labels and branded hangtags.

- Quality Assurance: Neoprene’s uniform polymer structure yields consistent material properties. Factories run each batch through durometer testing, density checks, and tensile strength evaluations to ensure each lot meets specs.

Cost-Efficiency Considerations

| Cost Factor | Neoprene (Typical) | Alternative Materials | Notes |

|---|---|---|---|

| Raw Material Price (per kg) | $5–$6 USD | PVC: $1–$2 USD | PVC cheaper but lacks elasticity, thermal insulation |

| Production Time (per batch) | 2–3 weeks (foam lamination & finishing) | Injected molded plastic: 4–6 weeks | Mold tooling for plastic is expensive and time-consuming |

| Waste Rate (%) | ~5% | EVA Foam: ~3% | Foam cutting waste is slightly higher but reusable as scraps |

| Printing Cost (per piece) | $0.20–$0.50 USD | TPU Cases: $0.30–$0.60 USD | Comparable costs; neoprene often allows more vivid prints |

Balancing Quality vs. Budget

- Budget Constraints: If a brand’s priority is purely low cost, PVC or EVA may seem attractive. However, neoprene’s durability often translates to fewer returns and better customer satisfaction over time.

- Value Proposition: Neoprene’s higher price point typically yields a more premium feel—customers perceive neoprene cases and bags as luxury items, which can justify a higher retail price.

Streamlined Supply Chain and OEM/ODM Flexibility

- Single-Source Production: Szoneier handles raw material sourcing, foam or sheet fabrication, printing, die-cutting, sewing, and final QC—all under one roof. This reduces lead times and minimizes errors due to miscommunications across multiple vendors.

- Scalable Production Lines: Whether you need 500 custom neoprene bear-shaped coasters or 50,000 black neoprene wet bag pouches with private-label hangtags, the same production line can scale up or down without sacrificing quality.

- Intellectual Property Protection: For private-label partnerships, Szoneier signs NDAs and provides secure data rooms for artwork and technical drawings. This reassures brands that their designs are protected.

How Is Neoprene Customized for Specific Brand Needs?

Neoprene can be tailored through various printing methods, laminate options, die-cut shapes, seam styles, and hardware attachments, enabling brands to create unique, eye-catching products.

Printing and Decoration Techniques

- Full-Color Sublimation Printing

- Ink is infused into the neoprene surface at high heat (around 180°C).

- Yields vibrant, all-over prints that won’t peel or crack.

- Ideal for camouflage patterns on neoprene gun slings or colorful artwork on tote bags.

- Screen Printing

- Special neoprene inks are applied via mesh screens.

- Good for single-color logos or simple text designs (e.g., brand name on a wine koozie).

- More cost-effective for small color runs (1–2 colors).

- Digital Printing (DTG-Style)

- Inkjet-based technology prints directly onto neoprene.

- Allows for photographic prints or gradient designs.

- Works best on neoprene sheets with nylon backing to optimize ink adhesion.

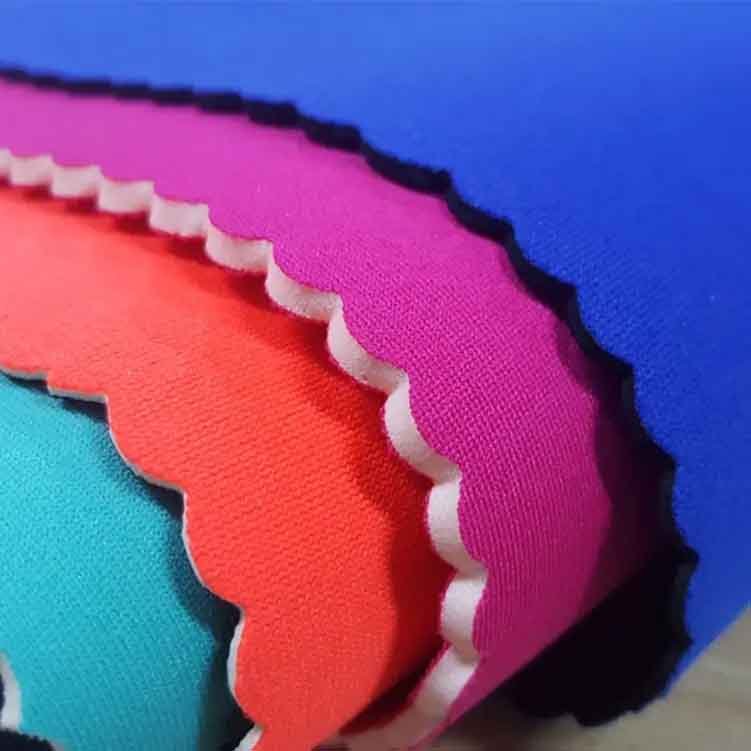

Lamination and Fabric Combinations

Standard neoprene foam can feel spongy on its own. Laminating adds structure and aesthetics:

- Nylon-Laminated Neoprene (2-Way Stretch)

- Offers tear resistance and smooth surface for printing.

- Used in neoprene laptop sleeves, camera bags, and fashion backpacks.

- Polyester-Laminated Neoprene

- Slightly less stretch but higher abrasion resistance.

- Commonly used in neoprene sports armbands or knee braces.

- Spandex or Lycra Lamination

- Adds high stretch recovery; perfect for body-contouring neoprene apparel like wetsuits, leggings, or knee sleeves.

Die-Cutting and Shape Customization

Neoprene’s foam structure allows for precision die-cutting:

| Cut Type | Description | Example Uses |

|---|---|---|

| Simple Die-Cut | Flat shapes cut from neoprene sheets using steel rule dies | Custom coasters, flat pouch inserts |

| Laser Cutting | Uses high-precision laser to cut intricate shapes and internal slots | Complex wearable parts, ventilation holes in knee braces |

| Water Jet Cutting | High-pressure water jet cuts without heat; maintains material integrity | Thick neoprene gaskets, industrial seals |

Edge Finishing and Seaming Techniques

- Serging (Overlock Stitch)

- Uses nylon or polyester thread to create a strong, slightly raised seam—classic look for wetsuits.

- Provides slight stretch, preventing seam splits under tension.

- Flatlock Stitch

- Seams lie flat against the fabric, reducing chafing; popular in activewear leggings and rash guards.

- Blind Stitch and Seam Taping

- For 100% waterproof applications (e.g., dry bags, medical braces).

- After stitching, seams are heat-sealed with rubber-based tape to eliminate water penetration.

Hardware Integration and Accessories

- Zippers and Zipper Tapes

- Waterproof coil zippers provide water resistance up to IPX4.

- Heavy-duty molded zippers (size #8 or #10) for easy opening/closing even when wet.

- Snaps and Velcro

- Plastic or metal snaps for quick closure (e.g., on neoprene roll-top lunch bags).

- Hook-and-loop Velcro for adjustable straps in fitness knee sleeves or gloves.

- Webbing and Buckles

- Nylon webbing straps sewn onto neoprene for carrying handles or shoulder straps.

- Plastic side-release buckles for adjustable closures on neoprene luggage straps.

Are There Sustainability or Environmental Considerations with Neoprene?

While traditional neoprene is petroleum-based, newer options—like limestone-based and recycled neoprene—reduce carbon footprint. Certifications such as Bluesign and CR-Free indicate more eco-friendly production.

Limestone-Based vs. Petroleum-Based Neoprene

| Factor | Petroleum-Based Neoprene | Limestone-Based Neoprene |

|---|---|---|

| Raw Material Source | Derived from chloroprene (a petroleum byproduct) | Uses crushed limestone and carbon black |

| Carbon Footprint | High (reliant on oil extraction and refining) | Lower (uses abundant mineral resources) |

| Cost | $5–$6 per kg | $6–$7 per kg (slightly higher upfront) |

| Performance | Standard water/chemical resistance | Comparable properties; slightly denser foam |

| Availability | Widely produced globally | Limited suppliers but growing adoption |

| Example Brands | SBR, DuPont-manufactured chloroprene foams | Yamamoto Limestone neoprene |

Why Limestone-Based Neoprene Matters

- Lower Greenhouse Gas Emissions: Production studies show limestone neoprene can reduce CO₂ emissions by 20–30% compared to petroleum-based alternatives.

- Supplier and Cost Dynamics: While costs are slightly higher per kilogram, many brands absorb this premium to market products as “eco-conscious.” Over time, economies of scale are expected to narrow the price gap.

- Quality Parity: Modern limestone neoprene delivers nearly identical flexibility, insulation, and resistance compared to traditional neoprene.

Recycled Neoprene Blends

- Post-Industrial Scrap (PIRS)

- Factories trim excess neoprene sheets; these scraps are reground and blended (up to 30%) into virgin neoprene.

- Benefits: Reduces landfill waste, slightly lowers raw material costs.

- Trade-Offs: May exhibit slight color variations or reduced tensile strength (around a 5% decrease).

- Post-Consumer Reclamation

- Reclaiming neoprene from end-of-life products such as old wetsuits.

- Industry estimates suggest only 10% of discarded neoprene is currently recycled; improving infrastructure could increase this to 50% by 2030.

- Brands like Patagonia and Adidas have pilot programs using reclaimed neoprene for limited-edition items.

Certifications to Look For

- Bluesign®: Ensures input chemicals meet strict environmental and safety criteria.

- CR-Free (Chloroprene Rubber Free): Indicates no harmful byproducts (ethylene thiourea) present.

- Global Recycled Standard (GRS): Verifies recycled content and chain-of-custody transparency.

End-of-Life Considerations and Circularity

- Recyclability: Closed-cell foam is challenging to recycle because it’s not soluble. However, some shredding and refolding methods exist:

- Mechanical Shredding: Neoprene pieces are shredded into crumb, then used as filler in carpet underlay or gym mats.

- Devulcanization Processes: Emerging technologies use heat and chemical catalysts to break cross-links, returning neoprene to a malleable state for remolding.

- Responsible Disposal: Encourage customers to return old neoprene gear for recycling; brands can partner with collection programs to offer discounts on new purchases.

What Challenges or Limitations Should Businesses Know When Working with Neoprene?

Neoprene is highly versatile but not without downsides: potential ETU residue allergen concerns, flammability under extreme heat, higher cost compared to basic plastics, and certain molding limitations (e.g., maximum thickness, tight-tolerance cutting challenges).

Summary: Key Challenges You Should Know

Neoprene can contain trace ETU (ethylene thiourea), a potential allergen; it is more flammable than silicone at high temperatures; costs are 2–3× higher than PVC; and extreme thicknesses (>7 mm) require custom tooling.

ETU Residue and Allergen Concerns

- What Is ETU?

- Ethylene thiourea is a byproduct formed during chloroprene polymerization. At high concentrations, ETU can cause skin irritation or allergies in sensitive individuals.

- Industry limits stipulate ETU content must be <15 ppm (parts per million) for consumer goods—Szoneier’s standard practice is <5 ppm to ensure safety.

- Mitigation Strategies

- Post-Manufacturing Washing: Factories wash neoprene sheets in water at 60°C for 10–15 minutes to reduce ETU concentrations.

- Certifications: CR-Free certified neoprene guarantees ETU levels well below regulatory thresholds.

Flammability and Heat Resistance

- Flammability Thresholds

- Neoprene ignites at around 250°C and will continue to burn if an external flame source is present. It emits hydrogen chloride gas during combustion, requiring careful handling in enclosed spaces.

- By contrast, silicone rubber has a higher ignition point (~350°C) and produces less toxic fumes.

- Business Implications

- For applications requiring exposure to open flames or extreme heat (e.g., industrial gaskets near furnaces), alternative materials might be safer.

- In consumer or military applications (e.g., fireproof bags), neoprene must comply with UL 94 flame-retardant ratings (V-0 or V-1).

Cost Comparison vs. Alternative Materials

| Material | Approximate Cost (per kg) | Key Properties | Typical Drawbacks |

|---|---|---|---|

| Neoprene | $5–$7 | High elasticity, insulation, chemical resistance | Priced higher; ETU concerns; moderate flammability |

| PVC Foam | $2–$3 | Inexpensive, waterproof, readily available | Rigid; poor elasticity; less insulation |

| EVA Foam | $3–$4 | Excellent cushioning, lightweight, easy to mold | Less heat resistance; lower chemical stability |

| Silicone Rubber | $8–$10 | Exceptional heat/chemical resistance, hypoallergenic | Very high cost; harder to bond to fabrics |

- When Budget Matters: If a brand’s primary need is basic padding without insulation (e.g., office chair armrests), EVA might suffice. However, if a product needs to function in cold, wet, or chemically harsh environments—neoprene remains the top choice.

Molding, Cutting, and Tolerance Limitations

- Maximum Thickness Constraints

- Standard neoprene sheets come up to 7 mm. Anything thicker requires layering or custom lamination, which can introduce delamination risks if not done correctly.

- Cutting Tolerances

- Die-cutting accuracy is typically ±0.5 mm. For applications needing tighter tolerances (±0.1 mm), laser cutting is more precise but slower and more expensive.

- Machining Concerns

- Machining solid neoprene blocks on CNC equipment can generate heat, risking local melting. Special tooling speeds (e.g., 2,000–3,000 RPM) and water-cooling are recommended for precision parts.

How Should Businesses Care for and Maintain Neoprene Products?

Proper care—washing in mild soap and water, air-drying out of direct sunlight, and avoiding sharp objects or oils—extends neoprene’s lifespan. Stored flat or rolled, with occasional talcum application to prevent sticking, neoprene items can last 5–10 years under normal use.

Quick Caring Tips to Keep Neoprene in Top Shape

Washing with mild soap, avoiding wringing, air-drying away from direct sunlight, storing flat or loosely rolled; keep away from oils, solvents, and rough surfaces to prevent premature degradation.

Cleaning Methods and Best Practices

- Hand Washing

- Step 1: Fill a basin with lukewarm water (30°C–35°C) and add 5–10 mL of mild detergent (e.g., baby shampoo or neoprene-specific cleaner).

- Step 2: Submerge the neoprene item, gently swish it for 2–3 minutes. Do not scrub aggressively—this can damage foam cells.

- Step 3: Rinse thoroughly in cool water to remove all soap residues.

- Step 4: Gently press out excess water (do not wring).

- Air Drying

- Lay flat on a clean towel or hang over a thick‐bar hanger in a shaded, well-ventilated area.

- Avoid direct sunlight; UV exposure accelerates foam degradation.

- Do not use a tumble dryer—high heat can denature neoprene’s polymer chains.

- Deodorizing and Mildew Prevention

- After drying, store in a breathable nylon bag with a small sachet of silica gel to reduce moisture.

- For lingering odors, spray with a 1:1 mixture of water and white vinegar; wipe gently and air dry again.

Storage Tips to Prevent Degradation

- Avoid Folding Sharp Creases: Repeated folding at the same spot can create weak points. If possible, store flat or rolled loosely.

- Temperature Control: Keep storage areas between 10°C and 25°C. Temperatures above 40°C can accelerate aging, while below 0°C can make neoprene brittle.

- Prevent Contact with Sharp Objects: Avoid placing neoprene products directly on concrete or rough metal. Even a small puncture can tear more easily over time.

Extending Product Longevity

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Rinse After Use (especially in saltwater or chlorinated water) | Immediately after use | Prevents salt and chlorine buildup, which degrade foam |

| Inspect Seams and Edges | Quarterly | Catches loose threads, weak spots, or small tears early |

| Apply Talcum Powder (for storage) | Every 3–6 months | Prevents inner surfaces from sticking together |

| Rotate Usage (for gear) | As needed | Prevents wear concentration on single product piece |

- Tip: If a small tear appears (≤10 mm), use neoprene cement or specialized rubber glue to patch it. For larger tears, consider professional re-seaming.

Conclusion

By now, you understand that neoprene’s unique combination of closed-cell foam insulation, elasticity, and chemical resistance stems from its carefully controlled emulsion polymerization. You’ve seen how different grades—from thin foam to dense sheets—fit everything from drink koozies to heavy-duty industrial seals. You’ve explored customization strategies—full-color printing, laminate options, die-cuts, and hardware attachments—and weighed sustainability options, including limestone-based and recycled blends. You’ve also learned the limitations—ETU residue, flammability, and cost—and best practices for caring, cleaning, and storing neoprene goods to maximize lifespan.

Now it’s time to take action. If you’re a brand, designer, or retailer wondering how to leverage neoprene’s versatility for your product line—whether it’s a designer laptop sleeve, a custom wetsuit for a surf competition, or branded neoprene koozies for your next promotional campaign—reach out to Szoneier. With over 18 years of expertise in neoprene R&D, manufacturing, and OEM/ODM services, Szoneier can provide free artwork design support, low MOQ prototyping, and rapid sampling to get your concept to market in record time. Contact us today for a detailed quote tailored to your exact specifications—and let’s create something exceptional together.