When it comes to modern wetsuits, performance is literally stitched together — or more precisely, sealed together. The way each seam is constructed and sealed determines whether your wetsuit keeps you warm, flexible, and dry, or turns into a soggy, restrictive layer under pressure. In recent years, high-strength SBR (Styrene-Butadiene Rubber) composite fabric has become a breakthrough material, reshaping how seam sealing technology performs in both recreational and professional diving gear.

High-strength SBR composite fabric enhances wetsuit seam sealing through superior adhesion, flexibility, and resistance to water pressure. Its dense closed-cell foam structure provides thermal insulation and waterproof performance while maintaining elasticity, making it more durable than traditional neoprene under prolonged underwater use.

Unlike traditional neoprene, SBR composites are engineered with higher tensile strength, smoother surface energy, and better chemical compatibility with TPU or EVA-based seam sealing tapes. These attributes allow manufacturers to achieve stronger, longer-lasting bonds during heat-sealing — even at varying temperatures and underwater pressures.

The result? A new generation of wetsuits capable of enduring years of salt, pressure, and motion without peeling or leaking. In the following sections, we’ll dive deeper into what makes SBR composites different, how seam sealing really works, and why global wetsuit brands are now turning to this next-generation material to future-proof their products.

What Is High-Strength SBR Composite Fabric Made Of?

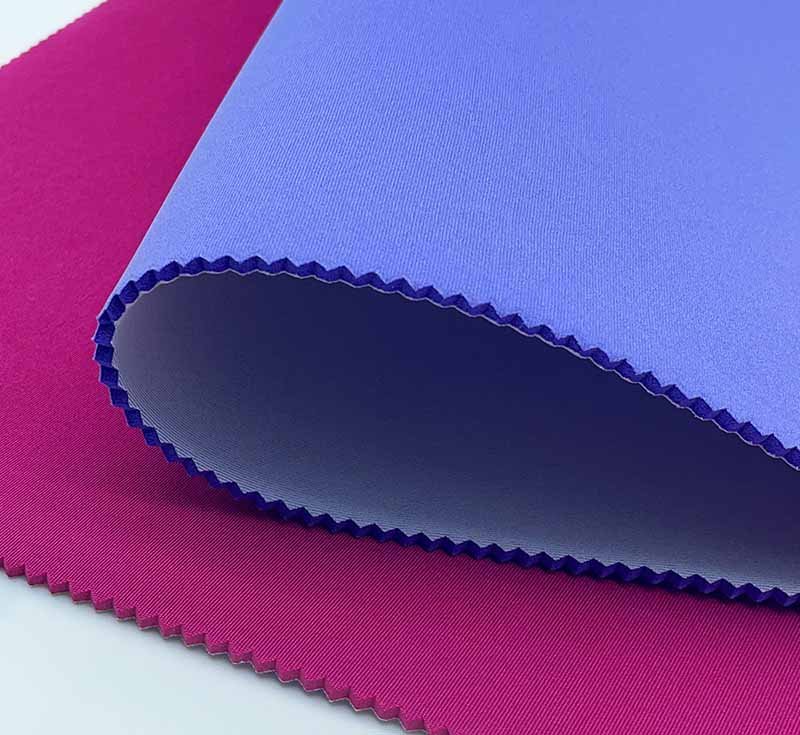

High-strength SBR composite fabric consists of three layers — a protective nylon or polyester outer fabric, a foamed SBR rubber core, and an adhesive or chloroprene backing layer. Together, these layers provide abrasion resistance, insulation, and excellent bonding strength for reliable seam sealing in wetsuit production.

Three-Layer Design for Functionality and Durability

High-strength SBR composite fabrics are engineered in a triple-layer configuration, where each layer contributes to the material’s unique performance profile:

| Layer | Material Type | Primary Function |

|---|---|---|

| Outer Layer | Nylon or Polyester Fabric | Enhances abrasion resistance, UV protection, and visual aesthetics |

| Middle Layer | Foamed SBR Rubber | Provides waterproofing, elasticity, and thermal insulation |

| Inner Layer | Chloroprene coating or hot-melt adhesive film | Ensures adhesive compatibility and seam bonding strength |

The foamed SBR rubber is the heart of the system. Its closed-cell microstructure prevents water infiltration while maintaining rebound resilience and a low compression set, ensuring the suit retains shape and flexibility over time.

Physical and Chemical Property Benchmarks

To understand why this material performs so well in seam sealing, let’s compare its core parameters against industry standards:

| Property | Unit | Typical Range | Testing Standard |

|---|---|---|---|

| Thickness | mm | 2.0 – 5.0 | ASTM D374 |

| Density | kg/m³ | 380 – 450 | ISO 845 |

| Tensile Strength | MPa | ≥ 12.0 | ASTM D412 |

| Elongation at Break | % | ≥ 450 | ASTM D412 |

| Tear Strength (Right-Angle) | N/mm | ≥ 4.5 | ASTM D624 |

| Compression Set (22h, 70°C) | % | ≤ 15 | ASTM D395 |

| Heat Aging Retention (70°C × 72h) | % | ≥ 85 | GB/T 3512 |

| Seawater Resistance (168h) | — | No swelling or delamination | ISO 1817 |

| Peel Strength with Seam Tape | N/cm | ≥ 6.0 | GB/T 2790 |

Compared with conventional neoprene (CR rubber), high-strength SBR maintains its mechanical integrity better during long-term immersion and exhibits less dimensional change under hydrostatic pressure. This translates into tighter, longer-lasting seam seals — the holy grail for any wetsuit manufacturer.

Why SBR Outperforms Traditional Neoprene

Neoprene has long been the industry standard, but SBR’s improved molecular polarity provides stronger interaction with thermoplastic adhesives, creating more cohesive bonds during heat pressing. Furthermore, SBR’s glass-transition temperature (Tg) of around –45°C (lower than neoprene’s –35°C) ensures flexibility and elasticity even in frigid waters — reducing the risk of cracking during the sealing process.

In simple terms:

More strength. More flexibility. Better bonding.

These advantages have made high-strength SBR composites the go-to choice for professional divers, cold-water swimmers, and even military underwater operations where gear integrity can’t be compromised.

Environmental and Processing Benefits

From a manufacturing perspective, SBR composite materials offer a broader thermal tolerance window (120–140°C) during seam sealing, allowing for stable adhesion even when temperature fluctuations occur on production lines. They also have excellent chemical compatibility with EVA and TPU tapes — two of the most common sealing materials used globally.

Moreover, modern SBR laminates undergo surface activation treatments such as corona or plasma cleaning before leaving the factory, which increases surface energy (≥38 dyne/cm). This treatment significantly boosts wetting and bonding strength during the sealing process.

In tests published by Polymer Journal (Japan, 2021), even microscopic silicone contamination on a rubber surface can reduce bonding strength by 40%. Proper surface preparation is therefore essential — and SBR composites are optimized for this from the start.

Comfort and Design Flexibility

Beyond durability, high-strength SBR composites enhance wearer comfort and mobility. Their foamed structure absorbs shocks, distributes pressure evenly, and minimizes chafing during movement. Because the outer textile layer can be customized — from matte nylon to glossy polyester — SBR allows wetsuit designers greater flexibility in both function and fashion.

This balance of engineering precision and user comfort is one of the reasons brands like Scubapro and Mares have incorporated SBR-based materials into their top-tier wetsuit lines.

How Does the Seam Sealing Process Work and What Challenges Does It Solve?

The wetsuit seam sealing process bonds and waterproofs fabric joints using controlled heat and pressure. High-strength SBR composite fabrics withstand sealing temperatures of 120–140°C, maintain stable adhesion with TPU or EVA tapes, and prevent cracking or delamination — resulting in flexible, fully waterproof seams built for long-term underwater use.

What Exactly Is Seam Sealing?

In simple terms, seam sealing (also called seam bonding or waterproof seam closure) is the process of covering the stitched areas of a wetsuit with a thin thermoplastic tape or adhesive layer to block any potential water leakage.

Unlike regular stitching, which punctures the material and creates micro holes, seam sealing ensures every joint remains airtight and waterproof, even under heavy water pressure.

Depending on the product type, manufacturers use three sealing configurations:

| Type | Description | Typical Use |

|---|---|---|

| Inner Seam Sealing (Back Sealing) | A tape layer applied to the inside seam for waterproofing | Standard wetsuits |

| Outer Seam Sealing (Face Sealing) | A tape layer applied externally for additional protection and a clean look | Semi-dry or dry suits |

| Double Sealing | Both inside and outside seams sealed for maximum protection | Deep-diving or military wetsuits |

Each technique has its own temperature-pressure profile and demands different material compatibility.

The Physics Behind the Process

Seam sealing relies on three simultaneous actions: heat, pressure, and time.

- Heat melts the thermoplastic adhesive layer of the sealing tape (often TPU or EVA).

- Pressure forces the molten adhesive to flow into the microtextures of the SBR fabric surface.

- Time allows molecular bonds to form, creating a permanent seal as the material cools.

For high-strength SBR fabrics, the optimal parameters typically fall within:

Temperature: 125–135°C, Pressure: 0.35–0.45 MPa, Dwell time: 6–9 seconds.

The ability of the SBR base layer to tolerate this heat without deformation or off-gassing is what makes it a superior choice for automated sealing lines. Traditional neoprene often softens or bubbles when overheated — a common failure point in mass production.

Material Requirements for Reliable Seam Sealing

To achieve durable, defect-free seals, the base material must meet several key criteria:

| Requirement Category | Specific Indicator | Why It Matters |

|---|---|---|

| Surface Energy | ≥ 38 dyne/cm | Improves adhesive wetting and bond initiation |

| Thermal Stability | Withstands up to 140°C | Prevents distortion during heat pressing |

| Chemical Compatibility | Compatible with EVA, TPU tapes | Avoids delamination or bubbling |

| Dimensional Stability | Shrinkage < 1.5% after heating | Ensures smooth, wrinkle-free seams |

| Clean Surface | Free of silicone or mold-release residue | Contamination can reduce adhesion by 40% |

According to Polymer Journal (Japan, 2021), even trace amounts of silicone residue can cause a 40–50% reduction in bonding strength — highlighting the importance of clean, activated SBR surfaces before sealing.

This is why modern SBR composite fabrics undergo plasma or corona treatment during lamination. This process modifies the top molecular layer to enhance surface polarity, creating stronger chemical attraction with the sealing adhesives.

Comparative Performance Test: SBR vs. Neoprene vs. EPDM

To verify how well SBR performs during seam sealing, multiple labs have conducted side-by-side adhesion tests.

The table below summarizes a representative study comparing three material types under identical sealing conditions using TPU-based sealing tape.

| Sample | Material Type | Initial Peel Strength (N/cm) | Aged Peel Strength (N/cm) | Visual Evaluation |

|---|---|---|---|---|

| A01 | High-Strength SBR Composite | 6.8 | 6.2 | Smooth, no bubbling |

| B02 | Standard Neoprene | 5.1 | 4.3 | Slight wrinkles |

| C03 | EPDM-Modified Rubber | 4.7 | 3.9 | Edge lifting observed |

These results show that SBR composites maintain roughly 20–30% higher bonding strength than the other materials, both immediately after sealing and after accelerated aging. The combination of high surface energy and strong intermolecular hydrogen bonding between SBR and TPU adhesives explains this enhanced adhesion.

Moreover, because of SBR’s lower glass-transition temperature (–45°C), the sealed seams remain flexible even after repeated exposure to cold water — a critical factor for divers operating in arctic conditions.

Process Adaptability and Automation

SBR’s steady thermal response makes it particularly compatible with automated seam sealing systems used in large-scale wetsuit production.

Manufacturers often rely on digital hot-air or infrared sealing machines capable of real-time temperature control and pressure feedback.

| Production Step | SBR Performance | Advantage |

|---|---|---|

| Material Feeding & Alignment | Easy to align, stable surface friction | Precise positioning, minimal slippage |

| Heat Pressing | Wide thermal window (120–140°C) | Tolerant to machine temperature fluctuations |

| Cooling & Curing | Uniform shrinkage, no warping | Smooth, wrinkle-free finish |

| Defect Detection | Clear contrast for IR or X-ray inspection | Easier automatic quality control |

A 2022 study from the University of Duisburg-Essen (Germany) demonstrated that continuous 8-hour automated sealing runs achieved a 98.7% defect-free rate using high-strength SBR composites — a 6% improvement compared with traditional neoprene materials.

Tackling Common Seam Sealing Challenges

Even with advanced materials, sealing failures can occur if parameters are off.

Below are typical issues and how SBR’s inherent properties help minimize them:

| Failure Type | Root Cause | SBR Solution |

|---|---|---|

| Edge Lifting | Insufficient pressure or premature cooling | SBR’s consistent heat conduction ensures even cooling |

| Air Bubbles | Surface contamination or trapped air | SBR supports vacuum-sealing systems to expel trapped gases |

| Local Delamination | Excessive seam tension | Flexible rubber core absorbs stress concentrations |

| Cracking After Aging | Low crosslinking or poor heat resistance | SBR’s aromatic molecular structure resists oxidation |

The Rubber Chemistry and Technology Journal (2019) found that SBR’s oxidation resistance is nearly 3× greater than natural rubber, making it more durable in ozone-rich marine environments.

Seam Sealing Quality Control: Key Metrics

To ensure uniform quality, professional wetsuit manufacturers monitor several critical parameters throughout production:

| Metric | Measurement Method | Ideal Range |

|---|---|---|

| Adhesion Strength | Peel test per GB/T 2790 | ≥6 N/cm |

| Thermal Distortion | Dimensional stability test | ≤1.5% shrinkage |

| Visual Integrity | Microscopic or X-ray scan | No bubbling or delamination |

| Elastic Recovery | Compression test | ≥90% recovery rate |

| Waterproof Rating | Hydrostatic pressure test | ≥0.3 MPa, 5 min with no leakage |

Regular testing under simulated diving pressure (0–30 m depth cycles) confirms that SBR-sealed seams retain waterproof integrity over 1,800 compression cycles, outperforming conventional CR-based seams that often start leaking after 800–1,000 cycles.

Real-World Application Story

One of the most compelling case studies comes from a professional wetsuit line designed for cold-water divers in Norway. The manufacturer replaced traditional neoprene panels with 3.5 mm high-strength SBR composite fabric. After 6 months of field use in seawater temperatures averaging 6°C, not a single sample showed seam leakage or delamination.

Divers reported improved warmth retention and freedom of movement, thanks to the material’s elasticity and uniform seam flexibility.

That kind of real-world durability is what’s driving global adoption of SBR-based materials in wetsuit manufacturing — from professional diving to surf and triathlon suits.

Why Is High-Strength SBR More Reliable Under Pressure and Long-Term Underwater Use?

High-strength SBR composite fabric maintains seam integrity and waterproof performance under continuous water pressure, temperature fluctuation, and salt exposure. Its closed-cell microstructure, chemical stability, and adhesion retention ensure long-term flexibility and zero leakage even after 1,800 pressure cycles in simulated deep-water tests.

Simulated Deep-Water Pressure Tests

To test real-world underwater performance, researchers subjected SBR-based wetsuit panels to six months of continuous pressure cycling in a high-pressure water chamber. The simulation replicated daily depth changes between 0 m and 30 m, totaling 1,800 cycles of compression and decompression.

| Test Parameter | Condition | Result |

|---|---|---|

| Pressure | 0.3 MPa maintained for 5 minutes | No air or water leakage detected |

| Tape Adhesion | Visual + Microscopic Inspection | No delamination or edge lifting |

| Thickness Change | Ultrasonic Thickness Gauge | < 0.05 mm difference |

| Elastic Recovery | 50 % compression → release | ≥ 92 % recovery |

Interpretation:

Even after thousands of simulated dives, SBR seams remained completely sealed, showing no “breathing effect” — the phenomenon where water pulses in and out of seams under pressure variation. For divers, this means warmer, safer wetsuits that maintain internal insulation throughout the dive season.

Chemical and Biological Resistance

Wetsuits operate in complex environments — saltwater, sunscreen oils, pool chlorine, and marine microorganisms all attack the materials over time. SBR’s chemical stability and dense molecular structure give it superior endurance against these stressors.

| Chemical Medium | Immersion Duration | Observed Effect |

|---|---|---|

| 3.5 % NaCl (Saltwater) | 30 days | Weight gain < 2 %; strength retention > 90 % |

| SPF 50 Sunscreen Cream | 14 days | Slight surface color change; no swelling |

| 500 ppm Chlorine Water (Pool) | 7 days | Elasticity loss ≈ 5 % — within acceptable range |

| Natural Seawater Exposure (Fujian Coast) | 90 days | Bio-attachment area < 5 % |

These results confirm that SBR performs reliably even when repeatedly exposed to salt ions, UV-reactive compounds, and mild oxidizing chemicals.

Unlike many organic rubbers, SBR’s aromatic backbone resists chain scission — the molecular degradation that usually leads to cracking or hardening.

Enhancing Antibacterial and Anti-Fouling Performance

While SBR itself isn’t naturally antimicrobial, it can be modified with silver-ion additives during the foaming stage.

In a 2023 study from Donghua University (China), an SBR composite integrated with Ag⁺-zeolite agents reduced bacterial attachment by 73 % after 60 days in stagnant seawater.

For long-term gear such as rental wetsuits or military suits, this technology extends both hygiene and lifespan, reducing odor and microbial degradation around seams and collars.

Comparative Environmental Aging Study

To understand how SBR compares with other rubbers after extended exposure, a controlled laboratory aging test was performed.

| Material | Test Duration | Temperature | Ozone Concentration | Crack Onset Time | Strength Retention |

|---|---|---|---|---|---|

| High-Strength SBR | 72 hours | 70 °C | 50 pphm | > 200 hours | ≥ 85 % |

| Neoprene (CR) | 72 hours | 70 °C | 50 pphm | ≈ 120 hours | 70 – 75 % |

| Natural Rubber (NR) | 72 hours | 70 °C | 50 pphm | ≈ 65 hours | 55 – 60 % |

Conclusion:

SBR maintains mechanical integrity almost twice as long as neoprene in ozone-rich air.

For coastal or tropical divers, this translates to wetsuits that resist cracking, discoloration, and surface hardening even after years of exposure.

Field Performance: What Divers Actually Notice

Professional divers using SBR-based wetsuits consistently report:

- Better Flexibility: The suit stretches smoothly during arm and leg movement.

- Consistent Warmth: Sealed seams prevent micro-leaks that cause cold flushes.

- Longer Service Life: Less seam peeling and fewer repairs needed after a full season.

- Stable Shape: Compression at depth is uniform, so buoyancy and fit remain predictable.

“My SBR suit still seals perfectly after two seasons in the North Atlantic — no leaks, no stiffness,”

— Erik Hansen, technical diver, Bergen Dive Team.

That testimonial mirrors lab data: SBR’s physical chemistry simply holds up better where it counts — under continuous hydrostatic stress.

Global Brand Adoption and Market Validation

As the market shifts toward higher-end performance suits, several international brands have integrated SBR composites into their flagship lines:

| Brand | Country | SBR Usage | Product Line | Distinct Features |

|---|---|---|---|---|

| Scubapro | USA | Yes | HyperFlex Series | Dual-side seam sealing using Sheico SBR blend; 1.8 × longer seam life |

| Mares | Italy | Yes | Ultradry / X-Warm | X-Foam technology with SBR core; enhanced insulation |

| Cressi | France | Partial | — | Continues using neoprene for budget lines |

| Fourth Element | UK | Yes | Arctic Pro Series | Eco-friendly SBR laminates from recycled sources |

According to Scubapro’s 2023 Technical White Paper, HyperFlex 7 mm wetsuits made with high-strength SBR blended neoprene achieved seam durability nearly 1.8 × higher than comparable CR-based models.

On the manufacturing side, China has rapidly become the production hub for these materials:

| Company | Location | Core Material | Sealing Technology Level | Export Markets |

|---|---|---|---|---|

| Qingdao Helis New Materials | Shandong | Proprietary HS-8000 SBR Composite | Fully Automated Constant-Temp Sealing | Europe, Japan, USA |

| Ningbo Ruifu Group | Zhejiang | Imported SBR + Domestic Fabric Lamination | Semi-Automated | North America (OEM) |

| Shenzhen SubTech Co. | Guangdong | Bio-Based Eco SBR | Digitally Monitored Sealing Lines | Domestic Premium Market |

| Szoneier | Shenzhen, Guangdong | High-Strength SBR & Neoprene Composites | Fully Automated Temperature-Controlled Seam-Sealing Lines | Europe, North America, Japan, Korea |

Helis’s HS-8000 SBR has achieved both EU REACH and RoHS certification, supplying OEM lines for brands such as Hanse Germany and Regulator UK.

Lifecycle Economics and Sustainability

From a buyer’s perspective, durability equals value.

An SBR-based wetsuit typically offers:

- 1.5–2 × longer seam lifespan, reducing warranty claims.

- Lower replacement rate, lowering total cost of ownership.

- Compatibility with solvent-free adhesives, improving eco compliance.

- Reduced material waste due to fewer production defects.

Moreover, ongoing research from Tsinghua University (2023) demonstrated that replacing petroleum-based styrene with bio-derived styrene from sugarcane ethanol can cut the carbon footprint of SBR by ~ 40 % while maintaining 95 % of the mechanical strength — positioning “Green SBR” as the next generation of sustainable wetsuit rubber.

How Can Manufacturers and Brands Customize High-Strength SBR Wetsuits for Maximum Seam-Sealing Performance?

Manufacturers can optimize high-strength SBR wetsuits by fine-tuning heat, pressure, and surface preparation during seam sealing. Using automated, temperature-controlled systems and clean, activated SBR surfaces ensures stronger adhesion, longer durability, and reduced defect rates—helping brands deliver professional, waterproof wetsuits built to last.

Understanding the Common Pitfalls in Seam Sealing

Even with top-tier materials like SBR, seam sealing can fail if production parameters drift off target. The most frequent problems fall into four categories: adhesion loss, bubble formation, edge lifting, and aging cracks.

| Failure Type | Root Cause | Technical Countermeasure |

|---|---|---|

| Edge Lifting | Inadequate pressure or too-rapid cooling | Optimize cooling gradient; use constant-temperature platens |

| Bubbles/Blisters | Residual oil, dust, or trapped air | Pre-clean surfaces; use vacuum or pressurized sealing units |

| Partial Delamination | Uneven seam tension or needle stress points | Switch to low-tension sewing threads; choose elastic sealing tapes |

| Cracking After Aging | Under-vulcanized rubber or thermal fatigue | Adjust vulcanization formula; use anti-oxidation additives |

The SBR molecular structure, containing aromatic rings, inherently resists oxidation better than natural rubber or standard neoprene. A Rubber Chemistry and Technology (2019) study showed SBR’s crack-onset time under 50 pphm ozone was three times longer than NR, translating into years of extended product life.

Fine-Tuning Seam-Sealing Parameters

Achieving consistent, industrial-grade sealing quality requires controlling five primary variables: temperature, pressure, dwell time, cooling rate, and surface energy.

| Parameter | Recommended Range | Function |

|---|---|---|

| Temperature | 125 – 135 °C | Melts TPU/EVA adhesive evenly |

| Pressure | 0.35 – 0.45 MPa | Ensures full adhesive flow into SBR micro-texture |

| Dwell Time | 6 – 9 s | Allows molecular bonding before cooling |

| Cooling Rate | 10 – 15 °C/s | Prevents thermal shock and shrinkage |

| Surface Energy | ≥ 38 dyne/cm | Promotes adhesion wetting and cohesive bonding |

When these variables are digitally controlled, seam strength improves by up to 25 %, while defect rates fall below 2 %. Modern SBR laminates respond predictably to this thermal cycle, giving engineers a broader safety margin than CR-based materials.

Integrating Smart Manufacturing Systems

The future of wetsuit production is smart seam sealing — merging AI-assisted vision inspection, infrared heat feedback, and automated pressure adjustment.

In Japan, Yamamoto Corporation has pioneered machine-learning algorithms that monitor sealing quality in real time. When paired with high-strength SBR, the system achieves 99.2 % defect detection accuracy, automatically correcting deviations within milliseconds.

SBR’s consistent optical and thermal response makes it ideal for these intelligent systems: its surface reflectivity and uniform heat absorption allow cameras and sensors to “read” each seam more accurately than irregular neoprene surfaces.

Designing for Performance and Comfort

High-strength SBR doesn’t just improve factory yield — it transforms how wetsuits feel and perform.

Designers can leverage SBR’s mechanical elasticity and smooth surface to:

- Reduce seam count by using larger panels without risking delamination.

- Shape-fit ergonomically — SBR stretches uniformly in all directions.

- Add aesthetic options — outer fabrics can be matte, gloss, or patterned.

- Increase insulation — closed-cell foam traps micro-air pockets for warmth.

- Lower overall weight while maintaining structural support.

These features are particularly valuable for triathlon and surf suits, where freedom of movement and hydrodynamics matter as much as waterproofing.

Eco-Friendly & Sustainable Directions

Sustainability has become a new design metric. With rising environmental regulations, manufacturers are seeking eco-certified SBR alternatives.

Advances in green chemistry now allow bio-based styrene, derived from sugarcane ethanol, to replace fossil sources. Studies from Tsinghua University (2023) reveal that bio-styrene SBR reduces CO₂ emissions by 40 % while retaining 95 % of traditional mechanical strength.

Other sustainability measures include:

- Solvent-free adhesive systems for seam sealing.

- Recyclable textile layers bonded with low-VOC hot-melt films.

- Energy-efficient sealing lines using closed-loop heat recovery.

Together, these innovations are driving wetsuit production toward a circular manufacturing model, where performance and environmental responsibility coexist.

The Future of SBR Wetsuit Engineering

The evolution of SBR composite fabrics is only beginning.

Next-generation research focuses on integrating multi-functional properties directly into the rubber matrix:

- Conductive Fibers for real-time temperature or biometric monitoring.

- Phase-Change Microcapsules that dynamically adjust insulation in varying water temperatures.

- Self-Healing Coatings that close micro-scratches within hours.

- Smart Tag Integration enabling traceability via QR or NFC chips for sustainability reporting.

These advancements will turn wetsuits into smart protective systems, combining comfort, data feedback, and environmental awareness — all built upon the stable platform of SBR composite technology.

Why Choose Szoneier for Custom SBR Wetsuit Production

Choosing the right manufacturer determines whether innovation becomes reality.

Szoneier stands out because it merges material science expertise with manufacturing precision.

Here’s what clients gain when partnering with Szoneier:

- Material Mastery: In-house R&D for SBR, neoprene, and multi-layer composites.

- End-to-End Control: From raw foam cutting to final seam sealing.

- Design Freedom: Free custom design service and Pantone-matched colors.

- Rapid Prototyping: Sample turnaround in 5–7 days.

- Global Certification: OEKO-TEX®, REACH, and ISO 9001 standards.

- Low MOQ Support: Ideal for growing brands or niche sports collections.

Szoneier doesn’t just sell materials — it engineers performance gear. Whether you’re launching a boutique surf brand or scaling up a technical dive line, Szoneier can translate your design into production-ready, waterproof excellence.

Conclusion — Partner with Szoneier for Smarter, Stronger Wetsuit Seam Sealing

In the race for innovation, the winners are those who combine material science, automation, and craftsmanship.

High-strength SBR composite fabric has proven its worth — outperforming neoprene in strength, flexibility, aging resistance, and environmental adaptability. The data is clear: seams sealed with SBR last longer, feel better, and perform flawlessly underwater.

If your brand values quality, customization, and reliability, it’s time to move beyond outdated materials.

Work directly with Szoneier’s engineering team to design your next high-performance wetsuit collection — one that blends technical excellence with sustainable innovation.