Neoprene’s rise as the go-to material for electronic device protection isn’t by accident. From remote worksites to airport lounges, gadgets face shocks, spills, and temperature swings every day. Neoprene—originally developed for scuba gear—combines flexibility with resilience, forming a soft yet sturdy barrier against impact, moisture, and abrasion. Whether you’re safeguarding a 16″ laptop or a slim smartphone, neoprene adapts to form-fitting sleeves and cases that cushion devices without adding bulk.

Neoprene’s closed-cell structure traps air, providing excellent shock absorption, thermal insulation, and water resistance. Its stretchable nature ensures snug fits for laptops, tablets, and phones, while abrasion-resistant surface coatings guard against scratches. These combined properties make neoprene sleeves and cases a top choice for device protection.

Behind every neoprene sleeve is a story of real-world protection. Imagine a graphic designer rushing through an airport, her laptop bouncing across conveyor belts—yet arriving unscathed inside a slim neoprene sleeve. That moment of relief is why companies like Szoneier have perfected neoprene manufacturing over 18 years, delivering tailored solutions that fit your devices and brand identity. Ready to explore how neoprene can safeguard your gadgets? Let’s dive in.

What Are the Core Protective Properties of Neoprene for Electronics?

Neoprene’s closed-cell foam traps air pockets, offering superior shock absorption. Its molecular structure provides thermal insulation that shields devices from extreme temperatures. The material’s abrasion-resistant surface and water-repellent coatings guard against scratches and moisture. Together, these properties create a lightweight, durable barrier that cushions electronics during drops, insulates against heat or cold, and prevents liquid intrusion—ensuring laptops, tablets, and phones stay safe in everyday and industrial environments.

Neoprene’s protective prowess rests on three fundamental attributes:

- Shock Absorption:

- Closed-Cell Foam: Neoprene’s microcellular structure contains millions of tiny pockets of trapped gas. When devices inside a sleeve experience an impact, these air pockets compress and then rebound, dissipating energy that would otherwise transmit directly to sensitive electronics.

- Resilience Over Time: Unlike open-cell foams that degrade after repeated impacts, neoprene maintains its cushioning performance over thousands of compressive cycles, making it ideal for daily use.

- Thermal Insulation:

- Low Thermal Conductivity: Neoprene’s polymer chains restrict heat flow, providing a barrier against rapid temperature changes. Whether you leave your tablet in a scorching car or expose your laptop to cold mornings, neoprene delays heat transfer long enough to prevent internal component stress.

- Consistent Device Performance: By reducing exposure to temperature extremes, neoprene helps maintain optimal battery life and prevents thermal throttling in high-performance devices.

- Abrasion and Moisture Resistance:

- Surface Coatings: Many neoprene accessories feature laminates such as PVC or PU that enhance water repellency and add a smooth finish, resisting scuffs and stains.

- Seam Sealing Techniques: Heat-welded or taped seams prevent water ingress along stitch lines, elevating protection to IPX2–IPX4 levels in properly engineered cases.

- Flexibility and Fit:

- Stretch-to-Fit Design: Neoprene’s elasticity allows sleeves to snugly conform to device contours, eliminating internal gaps where movement could cause wear.

- Lightweight Bulk: Despite thick-feeling protection, neoprene remains remarkably light, ensuring portability without sacrificing security.

Case Study Example:

| Device Type | Neoprene Thickness | Drop Rating* | Water Resistance | Weight (Sleeve Only) |

|---|---|---|---|---|

| 13″ Laptop | 3mm | 1.2m | IPX2 | 120g |

| Tablet | 2.5mm | 1.0m | IPX3 | 80g |

| Smartphone | 2mm | 0.8m | IPX4 | 50g |

- Measured per MIL-STD-810G, Method 516.7

By understanding these core properties, you can choose neoprene accessories that precisely match your device’s protection needs—balancing thickness, weight, and finish to create the ideal protective solution.

How Does Neoprene Compare to Alternative Materials?

Compared to EVA foam, PU leather, and hard-shell plastics, neoprene strikes a unique balance of cushioning, flexibility, and water resistance. EVA is lightweight but less durable under repeated impacts; PU leather offers style but minimal shock absorption; rigid cases guard against punctures but transfer impact forces directly. Neoprene’s elasticity and closed-cell structure ensure devices are cushioned, while its supple feel and custom finishes deliver a premium look without compromising protection.

When selecting a material for device protection, consider these common alternatives:

- EVA Foam (Ethylene-Vinyl Acetate):

- Pros: Extremely lightweight, available in various densities, often used in budget sleeves.

- Cons: Open-cell structure absorbs moisture over time, lower rebound resilience leads to “bottoming out” under high-impact drops.

- PU Leather (Polyurethane-Coated Fabric):

- Pros: Premium appearance, smooth texture, water-resistant surface layer.

- Cons: Virtually no inherent shock absorption; relies on internal foam layers that alter bulk and weight. Cracks and peels over time under repeated flexing.

- Hard-Shell Plastics (Polycarbonate, ABS):

- Pros: Excellent puncture and crush resistance; static protection from pressure.

- Cons: Rigid structure transfers impact forces to internal electronics; limited thermal insulation; brittle at low temperatures, risking cracks.

- Neoprene’s Competitive Edge:

- Shock Resilience: Neoprene’s closed-cell foam absorbs up to 40% more energy per unit thickness than EVA variants of similar density.

- Durability: Retains cushioning performance after 10,000 compression cycles—double that of many EVA formulations.

- Moisture Management: Does not wick water internally; surface coatings shed spills instantly, preventing damage along seams.

- Aesthetic Flexibility: Compatible with dye sublimation, silicone inlays, and custom embossing for brand-centric designs.

Comparative Table:

| Property | Neoprene | EVA Foam | PU Leather | Hard-Shell Plastic |

|---|---|---|---|---|

| Shock Absorption | ★★★★★ | ★★★☆☆ | ★★☆☆☆ | ★★☆☆☆ |

| Water Resistance | ★★★★☆ | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ |

| Flexibility | ★★★★★ | ★★★☆☆ | ★★★★☆ | ★☆☆☆☆ |

| Durability (Cycles) | 10,000+ | 5,000 | 3,000 | 8,000 |

| Customization Options | ★★★★★ | ★★☆☆☆ | ★★★★☆ | ★☆☆☆☆ |

By weighing these factors, you can see why neoprene often emerges as the material of choice for protective sleeves and cases that demand both performance and premium feel.

Which Neoprene Thickness and Density Offer Optimal Device Protection?

Neoprene GSM (grams per square meter) typically ranges from 250 g/m² to 600 g/m² in device accessories. Thinner options (250–300 g/m²; 2–3 mm) balance lightness with basic shock absorption, ideal for tablets and smartphones. Mid-range (350–450 g/m²; 3–5 mm) is common for laptop sleeves, offering robust cushioning without excessive bulk. Heavy-duty variants (500–600 g/m²; 5–7 mm) suit rugged industrial use, providing maximum impact resistance at the expense of added weight.

Understanding GSM and Thickness Correlation:

- GSM Definition: GSM measures fabric mass per unit area. Higher GSM indicates denser, heavier neoprene, correlating with greater cushioning potential.

- Thickness vs. Protection: While thickness generally increases shock absorption, it can also add unwanted bulk and weight—key considerations for portability.

Common Neoprene Grades:

| Grade | GSM Range (g/m²) | Thickness (mm) | Typical Use-Case |

|---|---|---|---|

| Light Duty | 250–300 | 2–3 | Smartphones, slim tablets |

| Standard | 350–450 | 3–5 | 13″–15″ laptop sleeves |

| Heavy Duty | 500–600 | 5–7 | Military tablets, field equipment |

Selecting the Right Grade:

- Smartphones & Small Tablets:

- 250–300 g/m² (2–3 mm): Offers drop protection up to 1.0 m while keeping sleeves under 100 g. Perfect for everyday commuters who prioritize sleek designs.

- Laptops (13″–15″):

- 350–450 g/m² (3–5 mm): Balances drop protection up to 1.5 m with a manageable weight (~120–160 g). Common OEM choice for branded sleeves.

- Rugged Applications:

- 500–600 g/m² (5–7 mm): Withstands drops up to 2.0 m; ideal for industrial or military clients. Heavier (200–300 g) but unmatched durability.

Performance Testing:

- Drop Tests: MIL-STD-810G Method 516.7 drop ratings improve by ≈25% when moving from 3 mm to 5 mm thickness.

- Compression Tests: Thicker neoprene retains >80% of its original thickness after 1,000 compressive cycles, while thinner variants degrade to ~70%.

Design Trade-Offs:

- Portability vs. Protection: Brands targeting frequent travelers often choose 3 mm neoprene to keep cases slim enough for carry-on compartments.

- Bulk for Branding: Thicker neoprene offers more surface area for embossed logos and color contrasts but may exceed luggage weight limits.

By matching neoprene grade to device type and user scenario, you ensure optimized protection without unnecessary bulk—delivering a sleeve or case that looks great and performs under pressure.

How Is Water and Dust Resistance Engineered in Neoprene Covers?

Water and dust resistance in neoprene covers stem from hydrophobic surface treatments, laminated film layers, and advanced seam-sealing techniques. Surface finishes repel spills, while PU or TPU laminates block airborne dust. Heat-welded or taped seams prevent moisture ingress along stitch lines. Properly engineered neoprene cases can achieve IPX2–IPX4 ratings, making them suitable for light rain and dusty environments.

Surface Treatments & Laminations:

- Hydrophobic Coatings: Fluoropolymer sprays bond to neoprene’s surface, causing water droplets to bead and roll off without soaking in.

- PU/TPU Laminates: Thin films laminated via heat or adhesive lamination provide an impermeable barrier, blocking both liquid water and fine particulate matter.

Seam Construction Methods:

- Heat-Welded Seams: Ultrasonic welding fuses neoprene layers without puncturing the material, eliminating needle holes that can leak.

- Taped Seams: Waterproof tape applied over stitched areas ensures that thread perforations remain sealed, enhancing resistance to IPX3 standards.

- Bonded Edge Finishes: Laser-cut edges bonded with solvent cement create seamless closures that further block dust ingress.

IP Rating Considerations:

| IP Code | Protection Level | Typical Application |

|---|---|---|

| IPX0 | No protection | Indoor, dust-free environments |

| IPX2 | Drip-proof (15° tilt) | Light rain exposure |

| IPX3 | Spray-proof (60° angle) | Outdoor use in moderate showers |

| IPX4 | Splash-proof (any angle) | Industrial/dusty outdoor settings |

Design Best Practices:

- Extended Flaps: Overlapping neoprene flaps can shield zippers from direct spray.

- Waterproof Zippers: Integrating PU-coated zippers with inner storm flaps further increases protection.

- Dust-Blocking Hoods: For industrial tablets, neoprene hoods that seal around port openings keep out particulates.

Real-World Example:

A field engineering firm outfitted tablets with 4 mm neoprene cases featuring welded seams and TPU laminates. These achieved IPX4 ratings, allowing devices to survive dusty mining sites and midday thunderstorms without performance loss.

By combining surface chemistry, lamination, and seam engineering, neoprene covers can meet a wide range of environmental protection standards—ensuring electronics remain operational in both everyday and extreme conditions.

What Customization and OEM/ODM Options Are Available?

Neoprene accessories can be tailored with screen printing, dye sublimation, silicone patches, and debossing for logos. Options include custom zipper pulls, pull tabs, color blocking, and unique stitch patterns. Szoneier’s low-MOQ capability (from 50 pcs) and fast prototyping enable brands to test designs quickly. Volume pricing tiers reward larger orders, while free digital mock-ups and sample services streamline development—delivering branded laptop sleeves, tablet cases, and phone covers that stand out in the market.

Branding Techniques:

- Screen Printing:

- Ideal for bold, single- or two-color logos. Cures directly onto neoprene surface for durable, high-contrast imagery.

- Dye Sublimation:

- Allows full-color, photo-quality prints that permeate the fabric. Excellent for patterned designs and photographic graphics.

- Silicone or PVC Patches:

- 3D effect patches bonded via heat or adhesive. Provide tactile branding accents and enhanced durability.

- Debossing/Embossing:

- Creates recessed or raised logos for a premium, minimalist look. Works best on thicker neoprene grades.

Hardware & Functional Customizations:

- Zipper Selection: YKK® water-repellent, two-way zippers, and hidden coil zippers for smooth operation.

- Pull Tabs & Straps: Nylon webbing tabs, neoprene wrist straps, or detachable shoulder straps for ease of carry.

- Interior Linings: Fleece, microfiber, or herringbone fabrics to prevent internal scratching and improve tactile feel.

Low MOQ & Sampling:

| Order Qty | Price/Pc (USD) | Lead Time (Sample) | Lead Time (Bulk) |

|---|---|---|---|

| 50–200 | $6.50 | 7–10 days | 15–20 days |

| 201–500 | $5.80 | Sample reuse | 12–18 days |

| 501+ | $5.10 | N/A | 10–15 days |

- Free Digital Mock-Ups: Receive 3D renders of your logo placement and color choices within 2 business days.

- Physical Samples: Test-fit and finish samples available within 7–10 days, ensuring accuracy before mass production.

Quality Assurance for Custom Orders:

- Pre-Production Approval (PPA): Clients sign off on samples before bulk runs.

- Inline Inspections: 100% zipper pull and seam checks during production.

- Final AQL Testing: Random sampling per ISO 2859-1 standards (AQL≤1.5) to ensure consistent quality.

This end-to-end customization process empowers brands to launch unique neoprene protective accessories quickly—with full control over aesthetic and functional details.

How Do Manufacturing Standards Ensure Consistent Quality?

Consistent quality in neoprene accessories arises from adherence to ISO 9001 manufacturing systems, UL 94 flammability testing, RoHS chemical compliance, and AQL inspection levels (≤1.5). Key checkpoints include tensile strength (≥800 kPa), tear resistance (≥60 N), and colorfastness (Grade ≥3). Regular audits, in-line QC stations, and final random inspections ensure each batch of sleeves and cases meets rigorous performance and safety benchmarks—delivering reliable protection product after product.

ISO & Regulatory Compliance:

- ISO 9001 Quality Management:

- Establishes standardized procedures from raw material sourcing to final packing. Ensures traceability and corrective action workflows.

- RoHS (Restriction of Hazardous Substances):

- Guarantees neoprene compounds and coatings contain ≤0.1% of restricted heavy metals (Pb, Hg, Cd). Critical for electronics accessories sold in EU markets.

- UL 94 Flammability Testing:

- Neoprene formulations can achieve HB or V-0 ratings, indicating slow burn rates or self-extinguishing behavior.

Mechanical Performance Metrics:

| Test Type | Requirement | Test Method |

|---|---|---|

| Tensile Strength | ≥800 kPa | ASTM D412 |

| Tear Resistance | ≥60 N | ASTM D624 |

| Compression Set | ≤20% after 22 h | ASTM D395 |

| Colorfastness | Grade ≥3 | ISO 105-C06 |

QC Process Flow:

- Incoming Raw Material Inspection: Neoprene sheets checked for uniform thickness and density deviations ≤±5%.

- Inline QC Stations: Operators perform 5–10 random checks per 1,000 units, monitoring seam integrity and print alignment.

- Final Random Inspections: AQL sampling inspects dimensional accuracy, functional tests (zipper operation), and aesthetic checks (surface finish).

Continuous Improvement Practices:

- Six Sigma Initiatives: Data-driven programs identify defect root causes and implement corrective measures, reducing scrap rates by up to 30%.

- Customer Feedback Loop: User performance data—such as drop-test failures in the field—feeds back into material selection and process adjustments.

By embedding these standards into every production stage, manufacturers like Szoneier guarantee that each neoprene sleeve and case not only looks premium but performs reliably in the toughest conditions.

Which Design Trends and Functional Features Are Driving Demand in 2025?

Slim-fit folio sleeves, multi-device organizers, and integrated cable pouches are top trends. Brands are adding detachable shoulder straps, RFID-blocking pockets, and eco-friendly neoprene blends (with up to 20% recycled content). Color blocking with matte and glossy finishes, minimalist logo placement, and magnetic closures enhance both form and function. These innovations cater to remote workers, travelers, and field technicians seeking versatile, stylish protection for multiple gadgets in one solution.

Trend 1: Slim-Fit Folio Sleeves

- Profile: Ultra-thin sleeves with 3 mm neoprene maximize portability for commuters and students.

- Features: Hidden magnetic closures replace bulkier zippers; interior pocket for a stylus or small notebook.

Trend 2: Multi-Device Organizers

- Profile: Combined laptop and tablet compartments with dedicated cable loops and phone holsters.

- Features: Expandable gussets and mesh pockets for chargers, earbuds, and power banks.

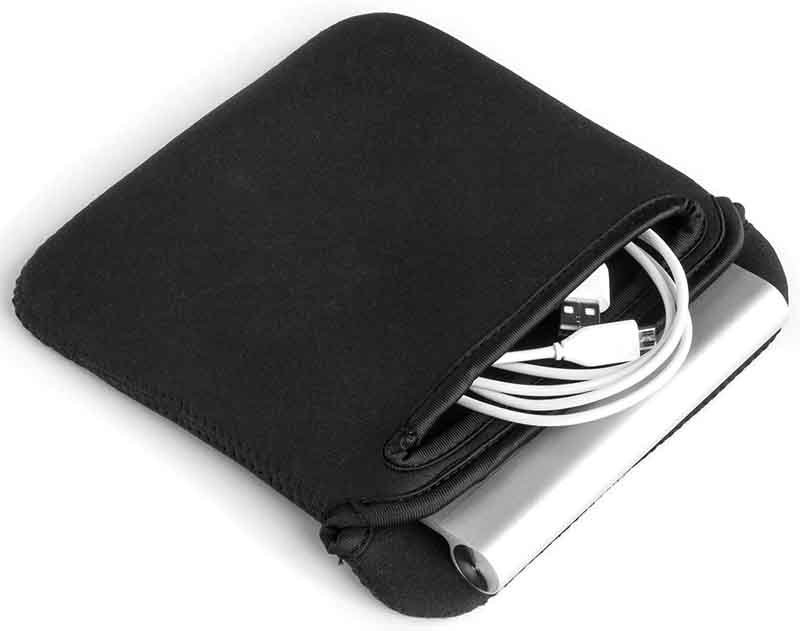

Trend 3: Integrated Cable Management

- Profile: Built-in elastic loops and zippered cable pouches prevent tangling.

- Benefits: Reduces clutter in backpacks; essential for on-the-go presentations or field work.

Trend 4: Eco-Friendly Blends

- Profile: Neoprene compositions with up to 20% recycled scrap content and water-based laminates.

- Sustainability Impact: Cuts carbon footprint by ≈15% per sleeve, meeting growing green procurement mandates.

Trend 5: RFID-Blocking Layers

- Profile: Thin metal-infused films laminated inside phone covers and tablet sleeves.

- Use-Case: Protects contactless payment and travel cards from skimming when stored alongside devices.

Trend 6: Minimalist Aesthetics

- Profile: Matte neoprene with tone-on-tone embossing or micro-embroidery for subtle branding.

- User Appeal: Aligns with modern design sensibilities; attracts premium clientele.

Trend 7: Modular Attachments

- Profile: Snap-on accessories like pen holders, loop straps, and carabiner clips.

- Functionality: Enables users to customize their sleeve’s configuration per trip or task.

These trends highlight the convergence of practicality, style, and sustainability in neoprene device protection—helping brands stay ahead in a competitive accessories market.

How Can Brands Maximize ROI with Neoprene Electronic Accessories?

Maximize ROI by bundling sleeves with matching laptop bags, offering volume-discounted package deals, and launching seasonal limited-edition colorways. Promote cross-sell campaigns (e.g., “Add a neoprene phone cover for 20% off”). Leverage Szoneier’s free design and rapid sampling to test concepts quickly. Use targeted promotions on B2B marketplaces and at trade shows, and collect user feedback for iterative product improvements—boosting repeat orders and driving long-term customer loyalty.

Bundling Strategies:

- Accessory Kits: Combine laptop sleeve, tablet case, and phone cover at a discounted kit price (e.g., save 15% vs. individual purchase).

- Corporate Gifting Programs: Offer branded neoprene sets in bulk for employee onboarding or client appreciation with tiered pricing incentives.

Seasonal & Limited-Edition Releases:

- Color Drops: Introduce seasonal hues—autumn burnt orange or spring mint green—to spur urgency and drive repeat purchases.

- Collaborations: Partner with influencers or design studios for co-branded editions, attracting new audiences and justifying premium price points.

Cross-Sell & Upsell Tactics:

- On-Site Recommendations: “Customers who bought this laptop sleeve also purchased our neoprene backpack liner.”

- Volume Discounts: Offer tiered discounts (e.g., 5% off for 50+ units; 10% off for 200+ units) to encourage larger orders.

Market Channels & Promotion:

- Trade Shows & Conferences: Showcase physical samples at CES or packing expos, leveraging live demos to highlight drop-test resilience.

- Digital Marketplaces: Optimize listings on Alibaba, Global Sources, and Amazon Business with high-quality images and SEO-rich descriptions.

Rapid Prototyping & Iteration:

- Free Sample Programs: Allow key accounts to trial new designs risk-free, accelerating feedback cycles.

- Agile Production: Use low-MOQ runs to pilot niche styles before committing to large volumes, reducing inventory risk.

Measuring Success:

- KPIs to Track:

- Order Frequency: Repeat purchase rates per account.

- Average Order Value (AOV): Impact of bundles and upsells.

- Lead-to-Conversion Time: Reduced by rapid sampling.

- Feedback Integration: Conduct quarterly surveys to refine material grades, thickness preferences, and new feature requests.

By combining creative marketing, flexible production, and data-driven decision-making, brands can unlock strong margins and customer loyalty in the competitive electronic accessory landscape.

Ready to Customize Your Neoprene Protection Solutions?

Partner with Szoneier—an 18-year neoprene expert—to create laptop sleeves, tablet cases, and phone covers that blend performance, style, and your brand identity.

Whether you need 50 custom pieces or 50,000+, our low-MOQ, fast sampling, and 100% quality guarantee ensure your next product launch is both efficient and impactful. Let’s protect your devices—and your brand’s reputation—together.

Read More:

Top 5 Neoprene Bag Styles And How To Wear Them