If you’ve ever designed or sourced a neoprene product — whether it’s a wetsuit, laptop sleeve, medical brace, or cooler bag — you’ve faced the same critical question: “How thick should the neoprene be?” On the surface, it seems simple. But in reality, neoprene thickness is one of the most complex, performance-impacting, and cost-sensitive choices in the entire production process.

Neoprene fabric thickness directly affects a product’s flexibility, warmth, protection, weight, and cost. Standard options like 1mm, 3mm, 5mm, and 7mm serve different industries, from lightweight sleeves to heavy-duty wetsuits. Thicker neoprene improves insulation and impact resistance but adds bulk and stiffness. Choosing the right thickness depends on your product’s usage, environment, user comfort, and manufacturing budget.

The wrong neoprene thickness can literally ruin your product. Too thin — it tears or offers no protection. Too thick — it becomes heavy, stiff, expensive, and uncomfortable. Finding the sweet spot means understanding your customers, application scenarios, and the physical science behind neoprene itself.

Let’s break it down step-by-step.

What Is Neoprene Fabric and How Does Thickness Affect Its Performance?

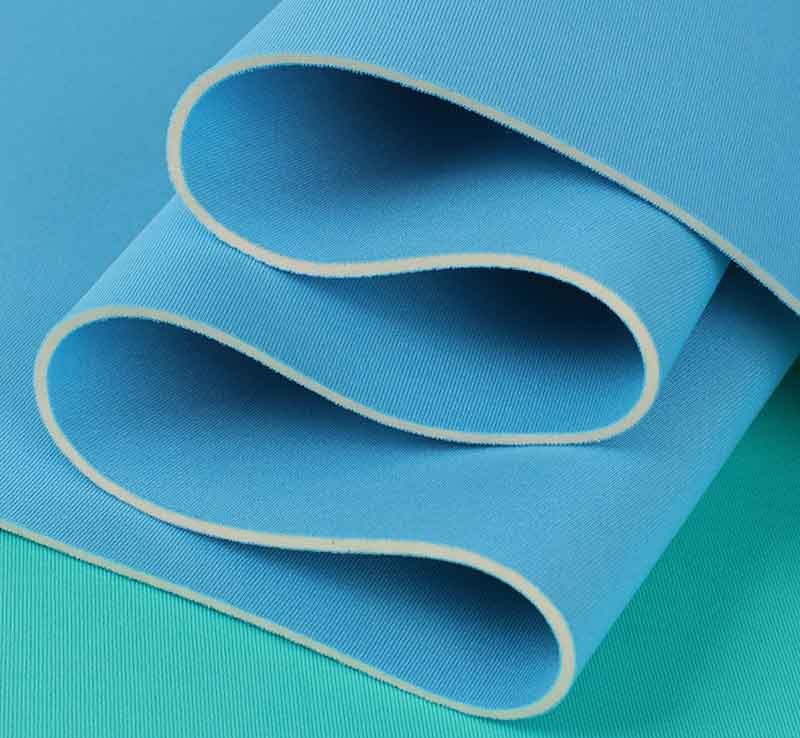

Neoprene is a closed-cell synthetic rubber known for its flexibility, insulation, waterproof properties, and cushioning. Its thickness dramatically changes how it performs: thicker neoprene increases insulation, durability, and protection, while thinner neoprene improves flexibility, breathability, and comfort. The correct thickness balances these factors depending on whether the product requires mobility, temperature control, or impact resistance.

What is Neoprene?

Neoprene, chemically called polychloroprene, was originally invented by DuPont in 1930. Today, it’s one of the most widely used technical fabrics in multiple industries because of its unique closed-cell foam structure. Inside neoprene:

- Air bubbles are trapped inside each microscopic cell.

- These cells create natural insulation and buoyancy.

- The rubber exterior offers excellent waterproof and weatherproof protection.

That’s why you see neoprene everywhere — from surfboards to laptop sleeves.

The 4 Key Performance Factors Controlled by Thickness

Let’s get very practical for OEM buyers:

| Performance Factor | Thin Neoprene | Thick Neoprene |

|---|---|---|

| Flexibility | Excellent | Limited |

| Insulation | Low | High |

| Shock Absorption | Minimal | Excellent |

| Weight | Lightweight | Heavy |

- Thinner neoprene (1mm-3mm):

- Flexible, form-fitting, lightweight

- Great for warm water wetsuits, sleeves, or casual bags.

- Thicker neoprene (5mm-7mm):

- Heavy-duty, highly protective

- Ideal for cold-water wetsuits, orthopedic braces, heavy-duty industrial padding.

The Science Behind Thickness Impact

- Thermal Insulation: Thicker neoprene traps more air inside its foam cells, providing superior insulation. That’s why divers use 7mm suits in cold water.

- Buoyancy: Thicker neoprene floats better due to more trapped air volume.

- Impact Resistance: Thicker neoprene absorbs shocks better, protecting fragile equipment or joints.

- Elasticity: As thickness increases, flexibility drops. Thicker neoprene resists stretching.

- Manufacturing Complexity: Thicker neoprene becomes much harder to cut, sew, and bond during production.

Which Neoprene Thicknesses Are Commonly Used in Manufacturing?

Manufacturers commonly use neoprene thicknesses of 1mm, 3mm, 5mm, and 7mm. Each thickness serves different applications depending on the product’s function. Thin neoprene (1mm) is used for lightweight items like sleeves and drink holders, while thick neoprene (5-7mm) is required for high-impact gear, wetsuits, and medical supports. Manufacturers select thickness based on the perfect balance of flexibility, protection, weight, and cost for each product.

Industry Standard Thickness Options

Let’s break down the most requested neoprene thicknesses from Szoneier’s real customer orders:

| Thickness | Industry Use | Product Examples |

|---|---|---|

| 1mm | Lightweight accessories | Laptop sleeves, camera pouches, fashion bags |

| 2mm | Entry-level water gear | Light wetsuits, beer koozies |

| 3mm | Versatile mid-range | Wetsuits, tablet covers, pet harnesses |

| 4mm | Sports braces & gear | Ankle supports, elbow braces |

| 5mm | Heavy-duty protection | Diving suits, orthopedic braces, industrial covers |

| 7mm | Extreme protection | Deep diving wetsuits, tactical padding |

Why These Thicknesses Dominate B2B Orders

- Raw material availability: Global neoprene sheet suppliers (Yamamoto, Sheico, Nam Liong, etc.) all stock these standard thicknesses.

- Tooling compatibility: Factories like Szoneier already have cutting molds, sewing machines, and heat presses optimized for these thicknesses.

- Buyer familiarity: International buyers are trained to spec products using these key sizes for consistency in design.

Real Sourcing Scenario Example

A European outdoor brand contacts Szoneier:

- Wants to develop a line of camping cookware protectors.

- Asks for light protection, water resistance, but easy packing.

- After review, Szoneier recommends 3mm neoprene: ➔ Soft enough for flexible packing ➔ Thick enough for scratch protection ➔ Not too bulky for backpackers

Neoprene Thickness Quick-Reference Table

| Thickness | Flexibility | Protection | Target Market |

|---|---|---|---|

| 1mm | Maximum | Minimal | Fashion bags, sleeves |

| 3mm | High | Moderate | Outdoor gear, wetsuits |

| 5mm | Moderate | High | Medical braces, diving suits |

| 7mm | Low | Maximum | Extreme cold or impact zones |

How to Choose Neoprene Thickness for Different Product Applications?

Choose neoprene thickness based on product category and functional needs. Lightweight items like laptop sleeves use 1-2mm neoprene for flexibility. Koozies use 2-3mm for insulation. Wetsuits vary from 3mm to 7mm depending on water temperature. Sports braces often require 5mm for support. Thicker neoprene provides better protection but sacrifices flexibility and comfort.

Bags, Laptop Sleeves, Cosmetic Cases (1-3mm)

- Key focus: Flexibility + Light Protection.

- Neoprene at 1mm feels soft, easy to fold, highly comfortable for travel gear.

- 2-3mm adds slight padding for bump protection.

Beverage Holders & Koozies (2-3mm)

- Key focus: Insulation + Grip.

- Thin neoprene hugs beverage containers tightly.

- Keeps drinks cooler while offering hand comfort.

| Product | Ideal Thickness |

|---|---|

| Slim cans | 2mm |

| Beer bottles | 3mm |

| Coffee sleeves | 2-3mm |

Wetsuits & Water Sports Gear (3-7mm)

| Water Temperature | Suggested Thickness |

|---|---|

| 24°C+ (Warm Water) | 1-3mm |

| 16-23°C (Mild Water) | 3-5mm |

| Below 15°C (Cold Water) | 5-7mm |

- Warmth retention is the primary driver here.

- 7mm wetsuits protect divers in icy waters.

Gloves, Socks & Flexible Accessories (1-5mm)

- Thin gloves (1-2mm): surfing, warm water.

- 3mm gloves: cold water diving, water sports.

- Socks: usually 2-5mm depending on temperature.

Sports Protection & Medical Braces (5-7mm)

- Joint braces (knee, elbow, wrist): 3-5mm.

- Weightlifting belts: 5-7mm for back support.

- Orthopedic gear prioritizes firm compression with light flexibility.

Is Thicker Neoprene Always Better for Durability and Protection?

Thicker neoprene offers superior protection, shock absorption, and insulation but reduces flexibility, comfort, and breathability. Optimal thickness depends on balancing safety needs with product function. For most daily-use items, excessive thickness adds bulk without significant benefit. Choosing the correct thickness ensures both durability and comfort.

Advantages of Going Thicker

- Better insulation for temperature-sensitive items.

- Enhanced protection against drops, shocks, or compressive forces.

- Longer lifespan in heavy-use environments.

- Better puncture resistance.

Why Thicker Isn’t Always Better

- Less flexible — difficult for wearables.

- Higher raw material and production cost.

- Difficult to fold or compress for packaging/shipping.

- Increases product weight.

Case Study: Laptop Sleeve vs Diving Suit

| Product | Optimal Thickness | Why? |

|---|---|---|

| Laptop Sleeve | 3mm | Slim, enough shock resistance |

| Diving Suit (Cold Water) | 7mm | Max thermal insulation |

How Does Neoprene Thickness Affect Production Cost and MOQ?

Thicker neoprene raises production costs due to higher raw material consumption, more complex cutting and sewing processes, and increased shipping volume. Thinner neoprene is easier to process and more economical for mass production. Thicker grades may require higher minimum order quantities (MOQs) due to waste control and setup costs.

Material Cost Impact

| Thickness | Cost per Sheet | Processing Complexity |

|---|---|---|

| 1mm | Low | Easy |

| 3mm | Moderate | Simple |

| 5mm | High | Complex |

| 7mm | Very High | Highly specialized |

Labor Impact

- Sewing thicker neoprene requires special needles and industrial sewing machines.

- Laminating thick panels may require additional heat-pressing or bonding.

MOQ Considerations for OEM Buyers

| Thickness | Typical MOQ (OEM Custom) |

|---|---|

| 1-3mm | 300-500 pcs |

| 5-7mm | 500-1000 pcs |

Do Neoprene Thickness Standards Vary Between Industries?

Yes. Neoprene thickness standards vary by industry to meet specific safety, performance, and comfort requirements. Wetsuits follow thermal insulation guidelines, medical braces prioritize joint support, while electronics cases focus on lightweight shock protection. Industry standards help OEM buyers determine optimal neoprene thickness when sourcing custom products.

Why Thickness Standards Matter for OEM Buyers

- Industry standards avoid product failure.

- International buyers often request specific thickness ranges to comply with safety and market norms.

- Choosing the wrong thickness could lead to poor product performance or even legal issues (medical & safety gear).

Industry-Specific Thickness Ranges

| Industry | Common Thickness | Key Performance |

|---|---|---|

| Wetsuits & Diving | 3mm – 7mm | Thermal insulation, buoyancy |

| Medical & Orthopedic | 3mm – 5mm | Joint support, compression |

| Bags & Electronics Cases | 1mm – 3mm | Lightweight shock absorption |

| Koozies & Drink Holders | 2mm – 3mm | Temperature control, grip |

| Sports & Tactical Gear | 5mm – 7mm | Impact protection, abrasion resistance |

Examples of International Standards

- Wetsuits: Often follow ISO 12402 buoyancy and warmth retention tests.

- Medical braces: Follow ASTM and CE compression, flexibility, and durability standards.

- Consumer electronics sleeves: Follow drop-test protocols where 3mm neoprene typically meets base impact safety.

OEM Buyer Tip

When working with OEM factories like Szoneier, always provide:

- End-use scenario

- User demographic (adult/child/professional/sport use)

- Market destination (EU, US, Japan)

This allows the factory to adjust thickness recommendations for full compliance.

How to Work with a Neoprene OEM Manufacturer for Custom Thickness?

Working with an experienced OEM neoprene manufacturer ensures you receive precise thickness control, material consistency, and full customization for your product line. Top suppliers like Szoneier offer free sampling, in-house testing, small MOQs, private label production, and global export expertise to meet brand and regulatory requirements.

Critical OEM Specifications to Prepare

| Specification | Importance |

|---|---|

| Thickness | Core structural function |

| Tolerance Range | Controls quality consistency |

| Lamination Fabric | Nylon, polyester, jersey, smooth skin |

| Color | Branding, Pantone color-matching |

| Logo Options | Silk screen, embossing, heat transfer |

| Production Volume | Impacts pricing and lead time |

The Sampling Process

At Szoneier:

- Sampling lead time: 5-7 business days

- Free design assistance.

- Pre-production samples for buyer approval.

- Thickness is measured to ±0.2mm tolerance for most products.

Full OEM/ODM Capability

Szoneier offers:

- Material R&D support.

- Custom molds & cutting tools.

- High-capacity production lines.

- In-house QC for thickness consistency.

- Export experience across Europe, North America, Australia, and Asia.

MOQ Flexibility for Global Buyers

| Buyer Type | MOQ Range |

|---|---|

| Small Startup | 300 pcs |

| Mid-Sized Brand | 500-1000 pcs |

| Large Retailer | 2000+ pcs |

Conclusion: Work with Szoneier to Get the Perfect Neoprene Thickness for Your Product

Choosing the right neoprene thickness is far more than selecting a number — it’s a balancing act between protection, comfort, flexibility, weight, cost, and end-user satisfaction. Whether you’re manufacturing dive suits, braces, laptop cases, or beverage holders, each thickness level serves a very different purpose.

As one of China’s leading neoprene OEM factories, Szoneier provides:

✅ Full range of thickness options from 1mm to 7mm

✅ OEM/ODM custom manufacturing services

✅ Free design and fast sampling

✅ Low MOQ for startup brands

✅ Consistent quality with in-house thickness inspection

✅ Export experience serving global clients

Contact Szoneier today for a free consultation, free samples, and factory-direct pricing to start your next neoprene product project.