When people first hear “neoprene,” they usually think about scuba wetsuits or promotional koozies. But in reality, neoprene fabric is one of the most versatile engineered textiles of our time. Developed as a synthetic rubber (polychloroprene), it comes in a wide range of forms—solid sheets, foams, laminated fabrics, and coated surfaces—each tuned for specific applications. The one factor that unites them all? Thickness.

Thickness determines whether neoprene acts as a flexible fashion material, a protective case, a thermal insulator, or a heavy-duty shock absorber. A 1 mm sheet may be perfect for lining gloves, while a 15 mm block may be used to dampen industrial vibration. Knowing the available thickness range—and what’s considered the thickest neoprene fabric—is crucial for buyers, designers, and engineers alike.

The thickest neoprene fabric available typically ranges from 10 mm to 20 mm. Standard consumer products use 0.5 mm to 7 mm, but ultra-thick sheets are produced for heavy-duty applications in marine, automotive, and industrial sectors.

Still, it’s not as simple as “the thicker, the better.” Thickness interacts with density, lamination, and finish. Too thin and neoprene loses insulation. Too thick and it becomes rigid, expensive, and difficult to work with. Success lies in matching the right thickness to the right end use.

And here’s where it gets practical. Think about a diver who relies on a 7 mm wetsuit in icy waters—comfort and safety depend on millimeters. Or a global logistics company that pads containers with 15 mm neoprene sheets to absorb shocks. Both cases highlight how choosing the correct thickness is not just technical—it’s a make-or-break decision.

This guide will take you deeper: from the fundamentals of neoprene thickness, to the maximum grades produced today, to how thickness impacts cost and flexibility. By the end, you’ll have clarity on which neoprene fabric suits your project, and how to source it with confidence.

What Is Neoprene Fabric and Why Does Thickness Matter?

Neoprene is a synthetic rubber (polychloroprene) used in foams, sheets, and laminated fabrics. Thickness matters because it affects insulation, durability, flexibility, and comfort.

Neoprene’s story begins in the lab—it was invented by DuPont in the 1930s as a synthetic alternative to natural rubber. Over time, engineers discovered that by foaming neoprene, laminating it with fabrics, and producing it in various thicknesses, it could serve radically different purposes: from dive suits to orthopedic braces to industrial seals.

Why thickness is critical:

- Insulation: Thicker neoprene traps more air, providing better thermal resistance. This is why wetsuits for cold waters use 5–7 mm, while tropical suits may use just 1–3 mm.

- Durability: More material means higher resistance to tearing, punctures, and long-term wear.

- Flexibility: Thinner neoprene bends and stretches more easily, while thicker grades can feel stiff.

- Protection: In bags and cases, thickness provides cushioning against impact.

Think about laptop sleeves: 3–5 mm neoprene is common because it balances protection with portability. In contrast, industrial gaskets might require 12 mm to withstand vibration and compression. Thickness directly connects the material’s performance with its use case.

Critically, thickness is not the only variable. Density (hardness), fabric lamination, and coatings can either enhance or diminish the role thickness plays. This means buyers should avoid focusing only on thickness numbers, and instead evaluate how the material behaves in real applications.

What Is the Standard Thickness Range of Neoprene?

Neoprene fabric is generally produced in thicknesses from 0.5 mm up to 10 mm. Most consumer and commercial applications fall within the 2 mm to 7 mm range, while extra-thin and extra-thick grades are available for specialized uses.

Understanding Neoprene Thickness Options

Neoprene thickness is not arbitrary — it is engineered to match performance requirements. Depending on the end product, you’ll find neoprene cut anywhere from ultra-thin 0.5 mm liners to heavy-duty 10+ mm sheets.

- Ultra-thin neoprene (0.5–1 mm): Often used as linings for gloves, fashion accessories, or lightweight braces. It’s flexible, breathable, and barely noticeable in thickness, making it ideal for comfort-driven designs.

- Thin-to-medium neoprene (2–3 mm): The most common thickness for items like beverage koozies, summer wetsuits, and protective sleeves. It offers light insulation while keeping weight and bulk low.

- Mid-range neoprene (4–5 mm): Popular for laptop bags, cooler bags, protective covers, and standard wetsuits. At this range, neoprene balances durability, thermal insulation, and flexibility.

- Thicker neoprene (6–7 mm): Favored for cold-water wetsuits, orthopedic supports, and high-protection gear. These grades retain body heat effectively but are less flexible, which is a trade-off divers and athletes accept for warmth and support.

- Extra-thick neoprene (8–10 mm+): Rare in consumer products but common in industrial, marine, or automotive applications. Used for vibration dampening, sealing gaskets, or heavy-duty covers.

Quick Comparison Table

| Thickness Range | Typical Application | Key Characteristics |

|---|---|---|

| 0.5–1 mm | Glove linings, braces, fashion items | Ultra-light, flexible |

| 2–3 mm | Koozies, sleeves, light wetsuits | Slim, basic insulation |

| 4–5 mm | Laptop bags, cooler bags, standard wetsuits | Protection + flexibility |

| 6–7 mm | Cold-water wetsuits, braces, pads | Strong insulation, less flexible |

| 8–10 mm+ | Industrial pads, marine covers, gaskets | Heavy-duty, impact resistant |

Key Takeaway:

Most buyers will source neoprene in the 2–7 mm range, since it covers 90% of consumer and commercial needs. However, suppliers like Szoneier can also provide extra-thin or extra-thick options to meet niche requirements — from fashion to industrial-grade protection.

If you’re not sure which thickness suits your project, request free samples from Szoneier and compare how each grade performs in real-world conditions.

Which Is the Thickest Neoprene Available on the Market?

The thickest neoprene sheets commercially available typically reach 15–20 mm, though the market norm tops out around 10 mm. Specialized suppliers—and custom operations—can produce ultra-thick neoprene for industrial, marine, and vibration-dampening applications.

Exploring Ultra-Thick Neoprene

Neoprene is typically thought of as a lightweight foam ranging from 2 to 7 mm—perfect for wetsuits, sleeves, and promotional gear. However, pushing beyond that opens a realm of heavy-duty possibilities. Let’s break down the ultra-thick end of the spectrum:

1. Industry Norm vs. Specialty Offerings

- Standard Commercial Range (up to ~10 mm): Most stock neoprene sheets top out at 8–10 mm. At this thickness, emphasis remains on flexibility, thermal insulation, and moderate protection.

- Ultra-Thick Specialty Grades (15–20 mm): Specialty mills and experienced factories can produce neoprene up to 15 mm and even 20 mm for niche applications. These are rarely stocked but made to order, often in limited quantities or specific roll lengths.

2. What Demands Ultra-Thick Neoprene?

- Vibration Damping & Shock Absorption: In industrial settings, ultra-thick neoprene acts like a sponge for vibration, reducing noise and protecting machinery and electronics from impact and oscillation damage.

- Marine & Buoyancy Applications: Think of custom-made floats, heavy-duty flotation panels, or marine bumpers—20 mm neoprene offers exceptional buoyancy and durability against abrasion and saltwater exposure.

- Specialized Sealing & Gasket Solutions: In automotive or construction, neoprene gaskets might require thick cross-sections to fill irregular gaps, resist compression, and maintain long-term sealing integrity under pressure.

3. Practical Trade-offs

- Reduced Flexibility: Once neoprene hits the upper ranges (15 mm+), it becomes significantly stiffer and heavier. It’s no longer wearable but purely structural.

- Higher Cost & Weight: Material usage—and thus cost—rises sharply with thickness. Transport, handling, and customization also become more complex.

- Fabrication Limits: Ultra-thick sheets sometimes need specialized cutting, gluing, or lamination tools. Not every factory can handle them efficiently.

4. Workaround: Bonded or Laminated Layers

A common solution: bond multiple thinner sheets (e.g., two 7 mm layers) to simulate a single ultra-thick 14 mm board. This approach:

- Maintains some flexibility between layers

- Simplifies handling and reduces rigidity

- Can sometimes be more cost-effective than sourcing a single 14+ mm block

5. Buyer Questions to Ask Suppliers

- Can you supply neoprene in 15 mm or 20 mm thickness?

- What’s the density (durometer) at these thicknesses?

- Is this thickness achieved via a single foam pour, or by bonding layers?

- Do you provide samples? What’s the tolerance (e.g., ±0.2 mm)?

- Which finishes or fabric laminations (if any) are available on ultra-thick sheets?

Comparison Table: Thick Neoprene Options

| Thickness (mm) | Typical Use Cases | Key Benefits | Considerations |

|---|---|---|---|

| 8–10 mm | Heavy-duty covers, cold-water wetsuits | Strong insulation and protection | Flexibility remains decent |

| 10–15 mm | Vibration pads, marine bumpers, industrial seals | High damping, impact resistance | Stiff, heavier, cost increases |

| 15–20 mm | Specialized marine panels, floatation devices | Maximum thickness for structural use | Very rigid, logistical challenges |

| Laminated stacks | Bonded layers (e.g., 2 × 7 mm = 14 mm) | More flexible, easier handling | Layer separation risk if bonding weak |

Takeaway:

While 10 mm neoprene is widely available, ultra-thick neoprene up to 20 mm does exist—though typically made to order for specific industrial or marine applications. Bonding multiple layers is a clever and often more practical alternative that balances thickness with flexibility.

How Do Thickness and Density (Hardness) Work Together?

Neoprene performance depends on both thickness and density. Thickness affects insulation and impact protection, while density (hardness or durometer) controls stiffness, compression resistance, and durability. A thin high-density neoprene can sometimes outperform a thicker low-density sheet in strength and support.

The Balance of Thickness and Density

When evaluating neoprene, many buyers focus only on millimeters. But that’s only half the story. The other half is density, often measured in hardness (Shore A or Shore C durometer ratings).

- Thickness = how much material is present (mm). More thickness usually means better insulation, cushioning, and durability.

- Density = how compact or heavy the foam is (kg/m³ or durometer). Higher density neoprene feels firmer, resists compression, and provides better support.

These two factors interact in complex ways:

1. Thin vs. Thick — With Density in Play

- A 3 mm high-density neoprene may feel stiffer and provide more compression resistance than a 5 mm low-density neoprene, even though it’s thinner.

- A 7 mm low-density neoprene may insulate better but collapse under weight or long-term compression, while a thinner, denser sheet can stay supportive.

2. Soft Comfort vs. Firm Support

- Low-density neoprene: Soft, compressible, lightweight. Great for koozies, fashion covers, or padding that prioritizes comfort.

- High-density neoprene: Firm, supportive, and durable. Ideal for medical braces, industrial seals, or vibration dampening.

3. Industry Applications

- Sportswear (wetsuits, gloves): Needs medium density with thickness matched to water temperature.

- Medical (braces, supports): Often medium to high density to prevent collapse and provide stability.

- Industrial (gaskets, pads): High density is critical, sometimes more important than thickness.

Comparison Table: Thickness vs. Density

| Property | Thin + Low Density | Thin + High Density | Thick + Low Density | Thick + High Density |

|---|---|---|---|---|

| Flexibility | Very high | Moderate | High | Low |

| Insulation | Minimal | Low | Strong | Very strong |

| Compression Resistance | Weak | Strong | Weak–moderate | Very strong |

| Typical Use Case | Glove lining, light covers | Orthopedic braces, straps | Cold-water wetsuits, padding | Industrial gaskets, vibration dampers |

4. Why Buyers Should Care

Thickness is easy to advertise, but without density information, the material can be misleading. A supplier may sell a “5 mm neoprene” that feels soft and collapses quickly because it’s low density. For applications like medical supports or industrial pads, this would be a failure.

Smart buyers should always request both thickness and density specifications. Ask for the durometer rating (Shore A/C), density in kg/m³, and compression-set test results. This ensures you’re comparing apples to apples.

Key Takeaway:

Thickness gives neoprene its insulation and cushioning, while density gives it strength and stability. The best-performing neoprene comes from matching these two variables to the application’s real-world demands.

Which Neoprene Thickness Is Best for Different Applications?

The best neoprene thickness depends on use: 2–3 mm for koozies and sleeves, 3–5 mm for bags and protective covers, 5–7 mm for wetsuits and braces, and 10+ mm for industrial or marine applications.

Matching Neoprene Thickness to Real-World Uses

Neoprene’s flexibility makes it popular across industries—from promotional drink coolers to deep-sea diving suits to industrial vibration pads. But the secret to success isn’t just “using neoprene.” It’s choosing the right thickness for the right job.

Let’s look at how different thickness ranges fit specific applications:

1. Bags, Sleeves, and Protective Covers (3–5 mm)

This is the sweet spot for consumer products like laptop sleeves, tablet cases, and cooler bags.

- 3 mm provides enough shock absorption without making products bulky.

- 5 mm is used when extra durability is needed—such as travel bags that endure heavy handling. Balance is key: too thin risks poor protection; too thick makes the product heavy and inflexible.

2. Beverage Koozies and Lightweight Accessories (2–3 mm)

Here, thickness is less about strength and more about insulation.

- 2 mm neoprene is common—it’s light, flexible, and cost-effective.

- Perfect for giveaways, branding items, and casual use. Extra thickness would only add unnecessary cost and weight.

3. Gloves, Sports Accessories, and Apparel (1–2 mm)

Neoprene gloves, cycling gear, or lightweight sportswear prioritize mobility over insulation.

- 1–2 mm neoprene provides stretch and flexibility without stiffness.

- This range is ideal for products that require dexterity (like fishing gloves or gym supports).

4. Wetsuits and Diving Gear (3–7 mm)

This is where neoprene thickness directly relates to survival in cold water.

- 3 mm wetsuits are common for tropical waters.

- 5 mm wetsuits are standard for moderate temperatures.

- 7 mm wetsuits are essential for cold waters, where insulation is critical. Divers often mix thicknesses: e.g., 5 mm body + 3 mm arms for better mobility.

5. Medical Braces and Orthopedic Supports (4–6 mm)

Neoprene braces use medium thickness for compression, warmth, and stability.

- 4 mm is flexible enough for knees and elbows.

- 6 mm provides stronger support for joints under strain. Here density matters too—firmer neoprene is often preferred.

6. Industrial, Automotive, and Marine (8–20 mm)

At the heavy-duty end of the scale:

- 8–12 mm neoprene is used for industrial gaskets, vibration pads, and protective mats.

- 15–20 mm neoprene (sometimes achieved by laminating layers) is used for marine bumpers, flotation panels, and shock-absorbing components. These grades are stiff and not wearable—they serve purely structural or protective functions.

Comparison Table: Neoprene Thickness by Application

| Application | Ideal Thickness | Key Benefits |

|---|---|---|

| Laptop sleeves, cooler bags | 3–5 mm | Balance of portability + shock protection |

| Beverage koozies, promos | 2–3 mm | Slim, light, affordable insulation |

| Gloves, sports gear | 1–2 mm | Flexibility and dexterity |

| Wetsuits & dive gear | 3–7 mm | Thermal insulation for varying water temps |

| Medical braces & supports | 4–6 mm | Compression, support, warmth |

| Industrial/marine pads | 8–20 mm | Heavy-duty sealing, impact, buoyancy |

Key Takeaway

Every millimeter matters. A laptop sleeve that’s too thin won’t protect your device. A wetsuit that’s too thick will restrict movement and comfort. And an industrial gasket that’s too thin may fail under compression.

How Do You Measure and Verify Neoprene Thickness?

Neoprene thickness is measured using calipers or micrometers, often following ASTM/ISO standards. Fabric laminations can increase total thickness.

Methods of measurement:

- Digital calipers: Clamp onto a sample and measure in mm.

- Micrometers: More precise for thin sheets.

- ASTM/ISO standards: Define methods for consistency.

Complications: Laminated fabrics (nylon, polyester) add thickness. Buyers should clarify if thickness includes or excludes fabric.

Buyer tips:

- Always request lab test reports.

- Ask suppliers for tolerance ranges (±0.2 mm common).

- Inspect multiple samples for consistency.

Trustworthy factories disclose both foam thickness and laminated thickness. Transparency here separates professional suppliers from unreliable ones.

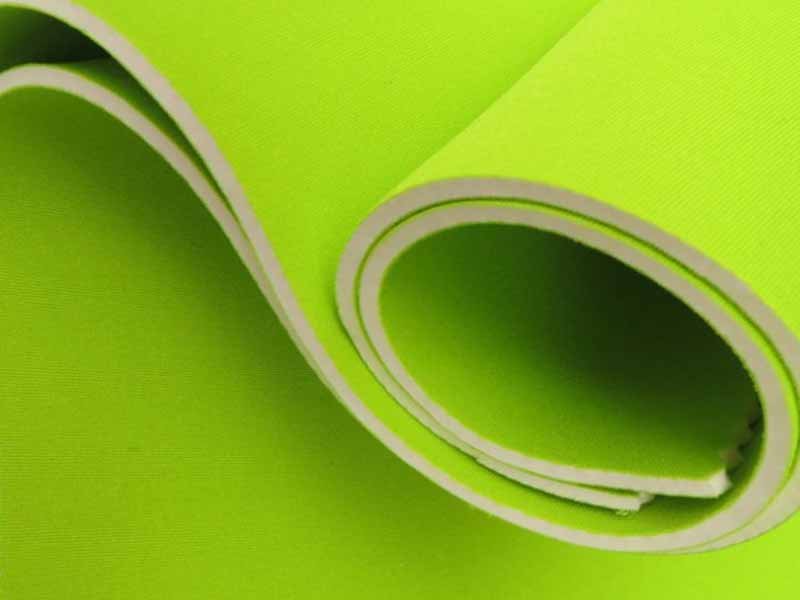

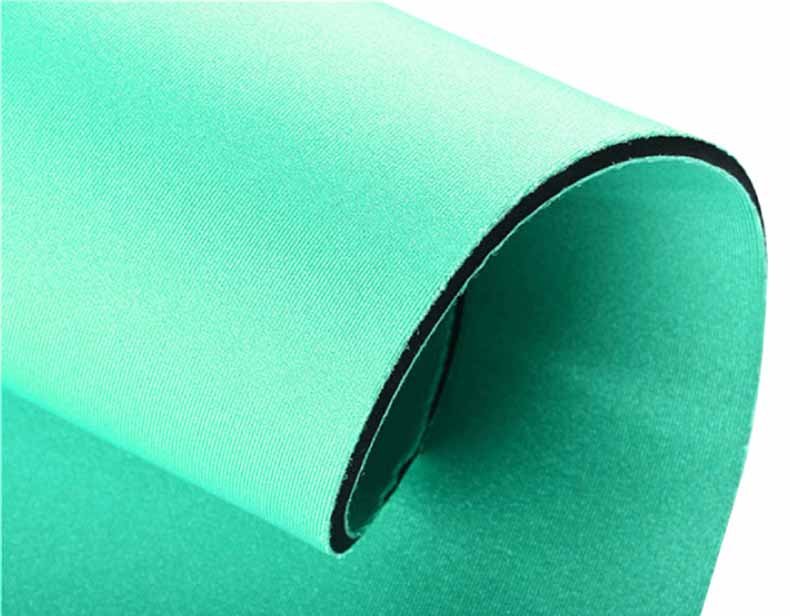

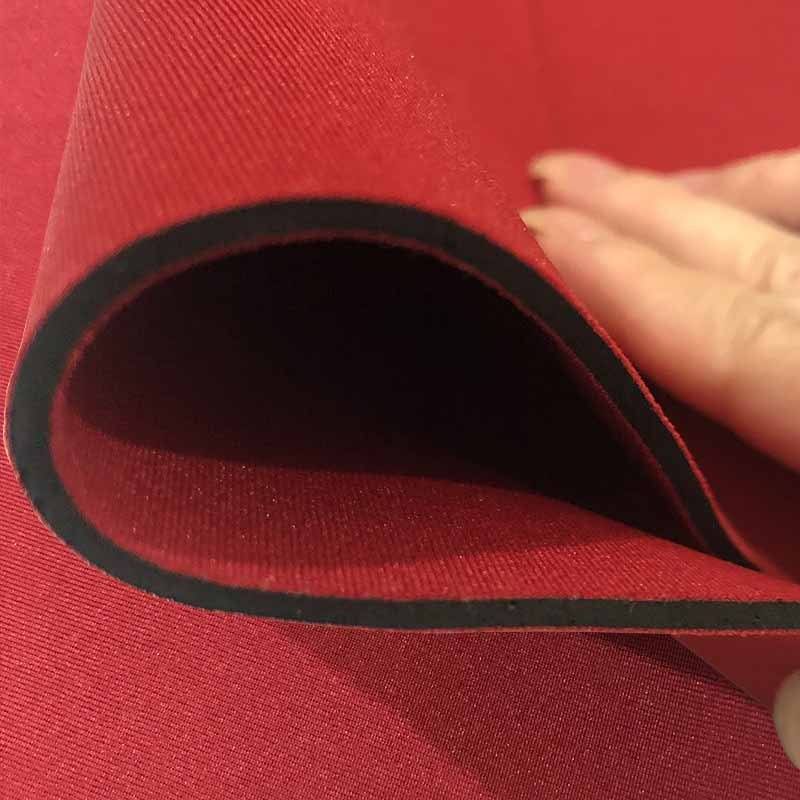

Do Coatings, Laminations, and Finishes Affect Thickness Choice?

Yes. Laminations (nylon, polyester, Lycra) and coatings (PU, silicone) increase total thickness while changing flexibility, abrasion resistance, and durability.

Neoprene rarely comes “naked.” Most products use laminations or surface finishes.

Fabric Laminations:

- Nylon: Durable, abrasion-resistant.

- Lycra: Stretchy, smooth.

- Kevlar: Industrial-strength abrasion protection.

Coatings:

- PU: Waterproofing.

- Silicone: Grip, durability.

- Antimicrobial: Hygiene for medical/fitness.

These layers add thickness. For example, a 5 mm neoprene core with double-sided nylon may measure 5.5–6 mm. Buyers must ask whether listed thickness includes these laminations.

Another effect: flexibility. Laminated neoprene may feel stiffer than bare foam, even at the same thickness.

How to Source Reliable Thick Neoprene Fabric?

Reliable sourcing means checking certifications (OEKO-TEX, REACH), verifying thickness with samples, and working with experienced factories that can customize finishes.

Checklist for buyers:

- Certifications: Look for OEKO-TEX, REACH, RoHS, ASTM.

- Sample Policy: Does the supplier offer free or low-cost samples?

- Transparency: Clear disclosure of foam vs laminated thickness.

- Customization: Ability to laminate, cut, emboss, and coat thick neoprene.

- Lead Times: For thick grades, ensure short and predictable delivery.

An experienced manufacturer like Szoneier brings over 18 years of expertise in neoprene R&D, lamination, and finished product manufacturing. With free design, low minimums, and fast sampling, Szoneier ensures that every millimeter of neoprene thickness meets international quality standards.

Conclusion: Why Thickness Matters and How Szoneier Can Help

Thickness in neoprene is more than a number—it’s the core of performance. From 0.5 mm linings to 20 mm industrial sheets, every use case depends on matching the right grade to the right function.

- Too thin? You risk poor insulation and weak durability.

- Too thick? You lose flexibility and overspend on material.

The smartest buyers ask the right questions: What is the true foam thickness? What density is supplied? Does lamination add to the total measurement?

At Szoneier, we help international buyers solve this challenge daily. Whether you need 3 mm neoprene sleeves, 7 mm wetsuit panels, or 15 mm marine-grade sheets, our factory delivers custom thickness, lamination, and finishing—with guaranteed quality and fast turnaround.

Ready to find the right neoprene thickness for your project? Contact Szoneier today to request free samples and start your custom order.