Have you ever wondered what makes certain products so durable and versatile? Imagine needing a material that can withstand harsh conditions, provide excellent insulation, and still be flexible enough for various applications. This is where neoprene comes into play. Neoprene is a game-changer in the manufacturing world, offering unmatched benefits for both producers and consumers. If you’re looking to enhance your product line with high-quality materials, understanding neoprene is essential.

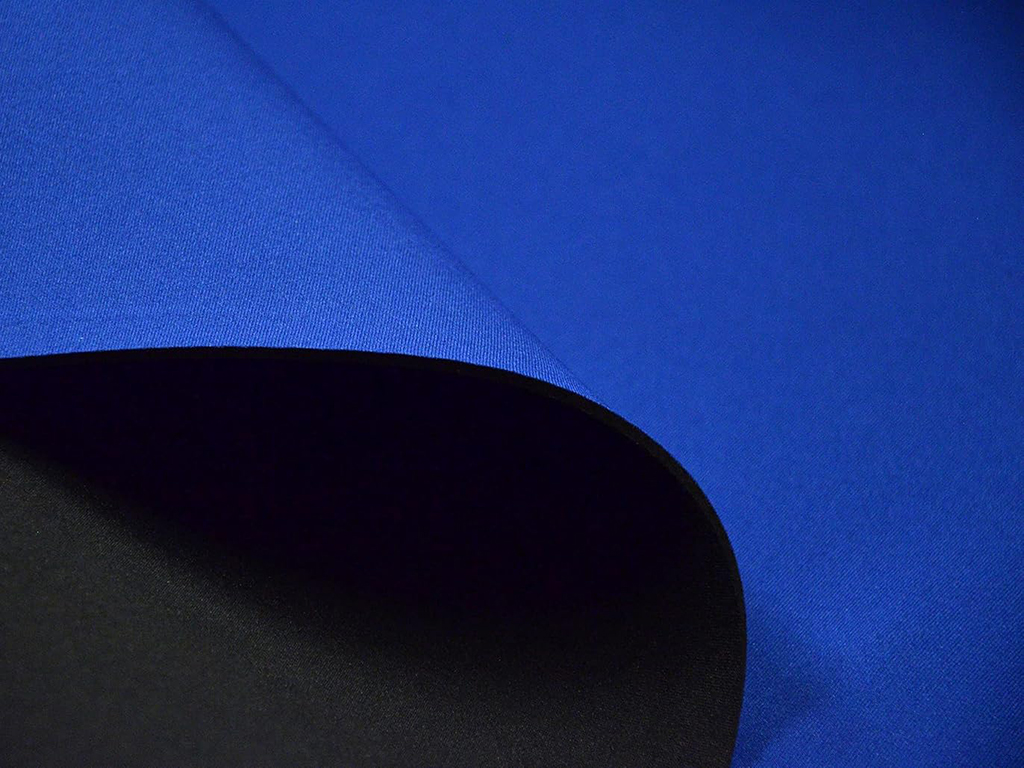

Neoprene is a synthetic rubber that offers durability, flexibility, and excellent insulation properties, making it ideal for a wide range of products.

I remember the first time I encountered neoprene in our factory. It was transforming our product quality, making our custom designs more resilient and appealing. This experience sparked my passion for neoprene and its endless possibilities.

What Is Neoprene?

What exactly is neoprene? Neoprene is a versatile synthetic rubber known for its durability and flexibility. It was first developed in the 1930s by DuPont as a substitute for natural rubber. Today, neoprene is widely used in various industries due to its unique properties.

Neoprene is a synthetic rubber made from polychloroprene, offering excellent resistance to weather, oil, and chemicals, making it suitable for diverse applications.

Let me share a story about how neoprene revolutionized our product offerings. When we first started using neoprene, we noticed a significant improvement in the quality and longevity of our products. This material allowed us to create items that not only met but exceeded our clients’ expectations.

Neoprene’s chemical structure is what sets it apart from other synthetic rubbers. Made from polychloroprene, neoprene has a unique molecular arrangement that provides its exceptional properties. This composition makes neoprene resistant to degradation from environmental factors such as UV rays, ozone, and extreme temperatures. Additionally, the presence of chlorine atoms in its structure enhances its fire-resistant qualities, making it a safe choice for various applications.

What Is Neoprene Used For?

Curious about the applications of neoprene? Neoprene’s versatility makes it suitable for a wide range of products, from everyday items to specialized equipment. Its ability to be molded and customized further expands its usability.

Neoprene is used in products like wetsuits, bags, gloves, koozies, and even electronic cases due to its flexibility, insulation, and protective qualities.

I recall working on a project where we developed neoprene gloves. The flexibility and durability of neoprene made these gloves not only comfortable but also long-lasting, perfect for various industrial applications.

Neoprene’s use extends beyond industrial applications. It’s a common material in consumer products such as laptop sleeves, camera cases, and even fashion accessories. The material’s ability to absorb shocks and provide thermal insulation makes it ideal for protecting delicate electronics and personal items. Moreover, its aesthetic versatility allows designers to create stylish and functional products that appeal to a broad audience.

Which Industries Commonly Use Neoprene?

Which sectors benefit the most from neoprene? Neoprene’s robust characteristics make it a favorite across various industries. Its adaptability allows it to meet the specific needs of each sector effectively.

Industries like automotive, fashion, electronics, sports, and healthcare extensively use neoprene for its durability, insulation, and protective properties.

Oneier has partnered with numerous brands in the automotive industry, providing high-quality neoprene components that enhance vehicle performance and safety. Our expertise in neoprene manufacturing ensures that each product meets the highest standards of quality and functionality.

In the automotive sector, neoprene is used for gaskets, seals, and vibration dampening components. Its resistance to oil, heat, and chemicals makes it an ideal material for these applications. Neoprene gaskets ensure that engines remain leak-free, while vibration dampers reduce noise and wear, enhancing the overall driving experience. By providing reliable and durable neoprene parts, manufacturers can improve vehicle longevity and performance.

What Are the Benefits of Using Neoprene for Custom Products?

Why choose neoprene for custom products? Neoprene offers numerous advantages that make it an excellent choice for various custom manufacturing needs. Its unique properties provide both functional and aesthetic benefits.

Using neoprene in custom products ensures durability, thermal insulation, water resistance, and the ability to customize designs, colors, and sizes to meet specific client needs.

When we started producing custom neoprene bags, the feedback was overwhelmingly positive. Clients appreciated the material’s ability to keep items insulated and protected, while also enjoying the wide range of customization options available.

One of the standout benefits of neoprene is its high degree of customization. Manufacturers can easily alter the color, texture, and design of neoprene products to match brand identities and consumer preferences. For instance, neoprene can be printed with logos, patterns, or unique color schemes, allowing businesses to create distinctive products that stand out in the market. Additionally, neoprene’s flexibility allows for the creation of various shapes and sizes, catering to diverse product requirements.

Customization Techniques

| Technique | Description |

|---|---|

| Screen Printing | Applying detailed designs and logos with ink. |

| Embroidery | Stitching patterns or logos for a textured look. |

| Laser Engraving | Creating precise and intricate designs. |

| Embossing | Raising designs to add depth and dimension. |

These techniques enable brands to create personalized products that resonate with their target audience, enhancing brand loyalty and recognition.

What Are the Disadvantages of Neoprene?

Is neoprene flawless? While neoprene has many advantages, it’s important to consider its limitations. Understanding these drawbacks can help in making informed decisions about its use in products.

Neoprene can be heavy compared to other materials, may not be as breathable, and its production involves chemicals that can impact the environment if not managed properly.

During one project, we faced challenges with neoprene’s weight in lightweight applications. It required careful design adjustments to balance durability with product weight, ensuring the final product met client expectations without compromising on functionality.

Neoprene production involves the use of chemicals that can be harmful to the environment if not handled responsibly. The manufacturing process releases volatile organic compounds (VOCs) and other pollutants. Additionally, neoprene is not biodegradable, contributing to long-term environmental pollution. However, advancements in production techniques and the development of eco-friendly neoprene alternatives are mitigating some of these impacts. Companies like Oneier are committed to sustainable practices, ensuring that our neoprene products are manufactured with minimal environmental footprint.

Is Neoprene 100% Waterproof?

Can neoprene completely prevent water ingress? Understanding the waterproof capabilities of neoprene is crucial for applications that require water resistance.

Neoprene is highly water-resistant and offers excellent waterproofing, but it is not entirely 100% waterproof as some moisture can still penetrate through seams and seams unless properly sealed.

In developing our neoprene wetsuits, we ensured that all seams were fully sealed to maximize water resistance. This attention to detail was crucial in creating products that perform well in water sports, providing both comfort and protection to users.

To achieve maximum waterproofing, various sealing techniques are employed during the manufacturing process. These include:

- Taping Seams: Applying waterproof tape over all seams to prevent water from seeping in.

- Gluing Seams: Using waterproof adhesives to bond seam areas tightly.

- Stitchless Construction: Creating products without seams or using bonded seams instead of stitched ones to eliminate potential entry points for water.

Implementing these techniques ensures that neoprene products maintain their integrity and functionality in wet conditions, making them reliable for users who need dependable water resistance.

Are There Customization Options Available with Neoprene Products?

Can neoprene products be personalized to fit specific needs? Customization is a key factor in creating unique and marketable products.

Yes, neoprene products can be customized in design, color, size, and packaging, allowing brands to create unique products that align with their identity and meet their customers’ preferences.

When we worked with a beach bag brand, they wanted bags that not only offered functionality but also reflected their vibrant brand image. By customizing the colors and adding their logo, we helped them create a product that resonated with their target audience and enhanced their brand presence.

Customization in neoprene products involves several techniques that allow for a high degree of personalization:

Design Customization

Brands can choose specific patterns, logos, and artwork to be printed or embroidered on neoprene products. This ensures that each product aligns with the brand’s visual identity and stands out in the market.

Color Customization

Neoprene comes in a wide range of colors, allowing brands to select hues that match their branding or seasonal themes. Custom color options help in creating products that are visually appealing and trendy.

Size and Shape Customization

Neoprene is highly flexible, enabling manufacturers to produce products in various sizes and shapes. This adaptability is essential for creating items like bags, gloves, and koozies that meet specific functional requirements.

Packaging Customization

Customized packaging enhances the overall presentation of neoprene products. Brands can design unique packaging solutions that reflect their identity and provide a memorable unboxing experience for customers.

These customization options not only enhance the aesthetic appeal of products but also improve their marketability, leading to increased customer satisfaction and brand loyalty.

How to Choose the Right Neoprene Product Manufacturer?

Looking for a reliable neoprene manufacturer? Choosing the right partner is crucial for the success of your custom products.

Selecting the right neoprene manufacturer involves evaluating their experience, quality control, customization capabilities, and reliability to ensure they can meet your specific needs and deliver high-quality products consistently.

At Oneierhttps://neoprene-bag.com/, we understand the importance of finding a trustworthy manufacturing partner. With over a decade of experience, 12 advanced production lines, and a commitment to quality, we are equipped to handle all your neoprene product needs efficiently and effectively.

Experience and Expertise

A manufacturer with extensive experience in neoprene production understands the material’s nuances and can offer valuable insights into the best practices for creating high-quality products. Oneier’s long-standing presence in the industry ensures that we have honed our skills and processes to deliver exceptional results.

Quality Control

Strict quality control measures are essential to ensure that each product meets the highest standards. At Oneier, we implement rigorous testing and inspection protocols at every stage of production to guarantee the durability, functionality, and aesthetic appeal of our neoprene products.

Customization Capabilities

The ability to customize products according to your specific requirements is a significant advantage. Oneier offers a wide range of customization options, including design, color, size, and packaging, allowing you to create unique products that align with your brand identity.

Reliability and Timeliness

Reliable manufacturers adhere to agreed-upon timelines and maintain consistent production schedules. Oneier prides itself on its punctuality and ability to manage large-scale orders efficiently, ensuring that your products are delivered on time, every time.

Communication and Support

Effective communication is vital for a smooth manufacturing process. Oneier provides responsive and transparent communication, keeping you informed about the progress of your orders and addressing any concerns promptly.

Competitive Pricing

Balancing cost with quality is essential for maintaining profitability. Oneier offers competitive pricing without compromising on the quality of our products, ensuring that you receive the best value for your investment.

Sustainability Practices

With increasing awareness of environmental impacts, choosing a manufacturer that prioritizes sustainability is important. Oneier is committed to eco-friendly practices, utilizing sustainable materials and implementing waste reduction strategies to minimize our environmental footprint.

By considering these factors, you can select a neoprene manufacturer that not only meets your production needs but also supports your business goals effectively.

Conclusion

Neoprene is a remarkable material that offers unparalleled benefits for a wide range of products. Its durability, flexibility, and customization options make it an ideal choice for brands looking to create high-quality, functional, and aesthetically pleasing items. At Oneier, we specialize in manufacturing top-tier neoprene products, including koozies, bags, gloves, and wetsuits, tailored to meet the unique needs of our clients.

With our extensive experience, advanced production lines, and commitment to quality, Oneier stands out as a reliable partner for your neoprene product needs. We understand the importance of timely delivery, exceptional quality, and customization in today’s competitive market. Our team is dedicated to providing you with products that not only meet but exceed your expectations, helping you build a strong and recognizable brand.

If you’re ready to elevate your product offerings with high-quality neoprene items, don’t hesitate to reach out. Contact me, Eric, at info@neoprene-bag.com or visit our website www.neoprene-bag.com to learn more about how Oneier can support your business. Let us help you create products that your customers will love and trust, ensuring your brand’s success in the competitive market.