Choosing the right material for outdoor and sun-exposed gear is more than just a matter of style—it’s a matter of longevity, safety, and customer satisfaction. Neoprene has earned its place as a versatile, durable synthetic rubber used in bags, koozies, gloves, covers, wetsuits, and more. But under the relentless rays of the sun, how well does neoprene hold up? In everyday scenarios—from beach tote bags left on sand dunes to promotional koozies handed out at summer festivals—UV exposure can lead to color fading, loss of elasticity, and premature material failure.

Neoprene offers moderate natural UV resistance due to its closed-cell structure, but prolonged sun exposure can degrade its polymer chains, leading to color fade and reduced flexibility. Adding UV stabilizers, surface coatings, and choosing optimized formulations can significantly enhance resistance, ensuring your neoprene products withstand sun, salt, and time.

Yet the story doesn’t end there. Imagine a boutique brand launching a neon-colored wetsuit line—only to find customers reporting cracked sleeves after a single sunny weekend. Or a promotional campaign where hundreds of branded koozies lose vibrancy by mid-summer. These cautionary tales underscore the need for science-backed UV solutions. Read on to discover how different neoprene formulations, additives, testing standards, and proper care can keep your products looking fresh and performing flawlessly under the sun’s glare.

What Is Neoprene and How Does It React to Sunlight?

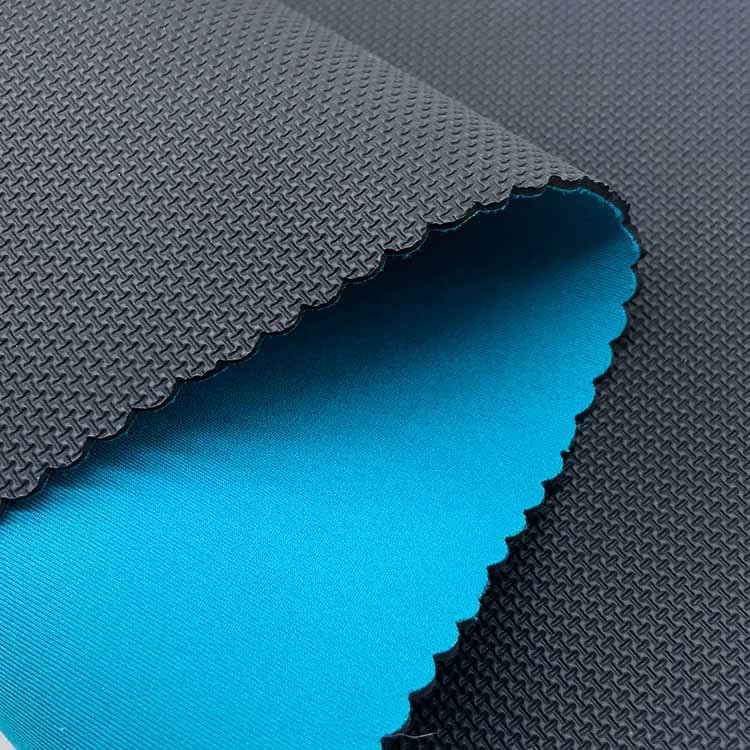

Neoprene is a chloroprene-based synthetic rubber known for flexibility, water resistance, and insulation. Its polymeric chains can absorb UV energy, causing molecular bonds to break over time. This UV-induced photodegradation manifests as surface chalking, color fading, and loss of tensile strength, especially in formulations without UV stabilizers.

Neoprene, first developed in the 1930s, revolutionized materials for harsh environments. Its closed-cell structure provides excellent insulation and buoyancy, making it indispensable in wetsuits and protective covers. However, like many polymers, neoprene’s resilience has limits when faced with ultraviolet (UV) radiation.

UV radiation encompasses wavelengths from 100 to 400 nm (UVA: 315–400 nm; UVB: 280–315 nm; UVC: 100–280 nm). While UVC is mostly filtered by the atmosphere, UVA and UVB penetrate clothing and material surfaces, initiating photochemical reactions. In neoprene, UV photons excite chlorine and carbon bonds within the polymer backbone, leading to chain scission (breakage) and cross-linking (unwanted bonding between chains). The resulting changes in molecular weight distribution cause embrittlement, surface chalking, and discoloration.

Mechanisms of UV Degradation:

- Chain Scission: Bond breakage reduces tensile strength and elongation at break.

- Photo-oxidation: Oxygen reacts with UV-activated polymer sites, forming carbonyl and hydroxyl groups—visible as surface chalk.

- Cross-Linking: Uncontrolled bonding increases stiffness, decreasing elasticity.

Factors Influencing UV Reaction:

- Formulation: Chlorine-based neoprene has moderate UV stability; limestone-based and blended variants may react differently.

- Color and Pigments: Dark pigments (carbon black) absorb UV energy, protecting the polymer, while light or transparent dyes offer minimal shielding.

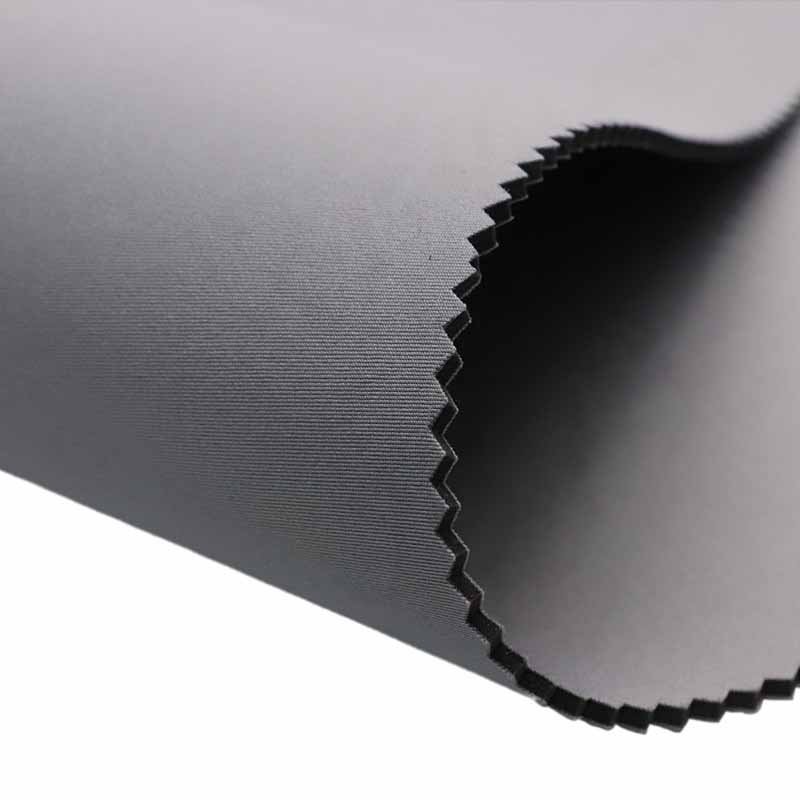

- Surface Finish: Smooth, sealed surfaces reduce oxygen diffusion and UV penetration compared to open-cell or matte finishes.

Real-World Implications:

Outdoor gear designers must account for UV exposure during product development. Wetsuits left on decks between surf sessions can degrade within months, whereas UV-stabilized items may last years. For promotional neoprene goods—koozies or covers—the difference between a product that fades by midsummer and one that keeps its branding intact defines customer satisfaction and brand reputation.

In the next sections, we’ll explore how optimized formulations and targeted additives can mitigate these UV effects, ensuring your neoprene products deliver both performance and longevity under the sun.

How Do Different Neoprene Formulations Handle UV Exposure?

Neoprene formulations vary: traditional chloroprene-based grades offer baseline UV stability, limestone-based neoprene has similar resistance, while CR/NBR blends can differ in flexibility and UV durability. Dope-dye (pre-colored) neoprene and pigment-loaded variants using carbon black significantly improve UV resilience by absorbing harmful rays.

Not all neoprene is created equal. The supplier landscape offers multiple formulations, each with unique UV response profiles. Understanding these differences empowers designers and procurement teams to match material selection with product lifecycle and application demands.

1. Chloroprene-Based Neoprene (CR):

- Composition: Polymerized chloroprene provides inherent flame retardancy and moderate UV resistance.

- UV Performance: Retains elasticity and color for 6–12 months in direct sun when unmodified.

- Use Cases: Standard wetsuits, protective sleeves, insulating panels.

2. Limestone-Based Neoprene:

- Composition: Replaces petroleum-derived carbon black with calcium carbonate fillers to reduce cost and environmental impact.

- UV Performance: Similar to CR, but may exhibit faster chalking without added UV stabilizers due to reduced carbon black content.

- Use Cases: Entry-level bags, budget covers, and eco-focused product lines.

3. CR/NBR Blends:

- Composition: Mixing nitrile rubber (NBR) enhances oil and chemical resistance at the expense of some UV stability.

- UV Performance: Blends show varied outcomes—higher NBR ratios can accelerate photo-oxidation unless countered by stabilizers.

- Use Cases: Industrial gloves, oil-resistant covers.

4. Dope-Dye & Pigment-Loaded Neoprene:

- Mechanism: Colorants added during polymerization (dope-dye) or as pigments (e.g., carbon black) disperse UV absorption evenly.

- UV Performance: Dope-dyed neoprene retains >80% original color after 500 hours in ASTM G154 accelerated UV exposure tests—versus <50% for surface-dyed equivalents.

- Use Cases: Fashion-forward bags, premium wetsuits, branded promotional items.

5. Alternative Polymers & Blends:

- Fluorine-Modified Neoprene: Incorporates fluorinated monomers for superior UV and chemical resistance, at a premium cost.

- EPDM/Neoprene Hybrids: Offer enhanced weathering resistance but may compromise on stretch and feel.

| Formulation | UV Stability (ASTM G154) | Tensile Retention | Cost Factor | Ideal Applications |

|---|---|---|---|---|

| Chloroprene (CR) | Moderate | 85% at 500 h | 1× | Standard wetsuits, general-purpose covers |

| Limestone-Based CR | Moderate | 80% at 500 h | 0.8× | Cost-sensitive bags, eco-conscious lines |

| CR/NBR Blend (70/30) | Lower | 75% at 500 h | 1.1× | Industrial gloves, chemical-resistant fits |

| Dope-Dye Neoprene | High | 90% at 500 h | 1.3× | Fashion items, premium promotional goods |

| Fluorine-Modified Neoprene | Very High | 95% at 500 h | 2× | Specialized outdoor equipment |

While cost often drives material choice, the true total cost of ownership emerges through product returns, warranty claims, and brand reputation. A wallet or cover that discolors quickly may lead to negative reviews, whereas investing in dope-dye or fluorine-modified neoprene can yield higher customer loyalty and premium pricing power.

Which Additives and Coatings Improve Neoprene’s UV Resistance?

Common UV-enhancing additives include carbon black (at ≥2% loading), titanium dioxide (TiO₂), and UV stabilizers such as HALS (Hindered Amine Light Stabilizers). Surface coatings—silicone or acrylic laminates—form a UV barrier. Each option balances effectiveness, cost, and impact on flexibility and appearance.

To mitigate UV damage, formulators and manufacturers leverage a toolbox of additives and surface treatments. Choosing the right combination ensures optimized protection without compromising the hand feel or performance of neoprene products.

1. Carbon Black:

- Mechanism: High-structure carbon black particles absorb UV energy and dissipate heat.

- Effectiveness: At 2–3% by weight, carbon black improves UV resistance by >40%, reducing surface chalking and preserving tensile strength.

- Drawback: Imparts a dark color, limiting use in light-toned or white neoprene goods.

2. Titanium Dioxide (TiO₂):

- Mechanism: TiO₂ nanoparticles scatter and absorb UV rays, especially UVB.

- Effectiveness: At 1–2% loading, enhances whiteness and UV stability; commonly used in white or pastel neoprene.

- Drawback: High loading (>3%) can stiffen the material and reduce stretch.

3. HALS (Hindered Amine Light Stabilizers):

- Mechanism: HALS intercept free radicals generated during UV exposure, preventing polymer chain degradation.

- Effectiveness: Provides long-term protection—HALS remain active even after extended UV exposure.

- Drawback: HALS are relatively expensive and may impart slight yellowing over time.

4. UV Absorbers (Benzotriazoles, Benzophenones):

- Mechanism: UV absorbers chemically convert UV energy into heat or harmless wavelengths.

- Effectiveness: Often combined with HALS for synergistic protection.

- Drawback: Leaching over time can reduce efficacy; requires encapsulation in polymer matrix.

5. Surface Coatings & Laminates:

- Types: Silicone, acrylic, and urethane coatings form a physical barrier to UV.

- Application: Applied via dip coating or lamination.

- Effectiveness: Blocks >90% of UV at 25–50 micron thickness.

- Drawback: Adds weight and may alter surface grip.

| Additive/Coating | UV Protection Gain | Effect on Flexibility | Typical Loading/Thickness | Cost Impact |

|---|---|---|---|---|

| Carbon Black (2–3%) | +40% | Minimal | 2–3% w/w | Low |

| TiO₂ (1–2%) | +35% | Moderate stiffness | 1–2% w/w | Low–Medium |

| HALS (1%) | +50% | Negligible | 1% w/w | High |

| UV Absorbers (0.5–1%) | +30% | Negligible | 0.5–1% w/w | Medium |

| Silicone Coating (25μm) | +90% | Minimal | 25 microns | Medium–High |

Balancing Act:

Formulators must weigh performance against cost. A premium wetsuit might justify HALS plus silicone coating. Conversely, promotional koozies may rely solely on carbon black and TiO₂ to hit tight budgets. By partnering with a factory like Szoneier, brands access expert guidance on additive selection and process optimization to suit price points and performance goals.

What Standards and Tests Verify UV Durability in Neoprene?

Neoprene UV durability is measured using standardized accelerated weathering tests like ASTM G154 and ISO 4892-3, which simulate sunlight via UV lamps and humidity cycles. Tensile strength, elongation, and color retention metrics after set hours indicate material resilience and predict real-world service life.

Assessing UV resistance requires rigorous testing protocols that replicate years of sun exposure in days or weeks. Below are the most prevalent standards and methods:

1. ASTM G154 – UV Fluorescent Lamp Exposure:

- Overview: Uses UVA-340 lamps emitting wavelengths between 295–365 nm to simulate sunlight. Cyclic exposure alternates UV light and condensation phases.

- Procedure: Samples undergo cycles (e.g., 8 hours UV at 60°C followed by 4 hours condensation at 50°C).

- Evaluation Metrics: Tensile strength retention, elongation at break, color ΔE (CIE Lab*), surface chalk rating.

2. ISO 4892-3 – Xenon Arc Testing:

- Overview: Employs xenon arc lamps covering full solar spectrum including visible and infrared rays.

- Procedure: Continuous exposure with controlled irradiance and temperature, optionally including water spray.

- Evaluation Metrics: Similar mechanical and color measurements, plus gloss retention.

3. Real-World Outdoor Exposure:

- Overview: Samples placed in geographic locations (Arizona or Florida) with high sun intensity. Months-long studies record natural degradation.

- Benefits/Drawbacks: Most accurate but time-consuming and weather-dependent.

4. Data Interpretation:

| Test Standard | Duration (hrs) | Tensile Retention (%) | ΔE Color Change | Application Relevance |

|---|---|---|---|---|

| ASTM G154 Cycle 1 | 500 | ≥80 | ≤3 | General consumer products |

| ISO 4892-3 | 1000 | ≥75 | ≤4 | High-end outdoor equipment |

| Outdoor Florida | 12 months | ≥70 | ≤5 | Real-world performance benchmark |

While accelerated tests offer rapid insights, they can over- or under-estimate real-world outcomes. Laboratories must correlate lab data with field results to refine rubber formulations. Brands should request both accelerated and field test data from suppliers like Szoneier to ensure reliable product performance.

Why Does UV Resistance Matter for Bags, Koozies, and Wetsuits?

UV resistance extends product lifespan, maintains visual appeal, and protects structural integrity. For neoprene bags and koozies, it prevents branding from fading; for wetsuits, it safeguards elasticity and thermal insulation. Superior UV performance reduces customer complaints, warranty claims, and environmental waste.

The practical importance of UV-resistant neoprene spans functional, economic, and ecological dimensions:

1. Brand Reputation & Customer Trust:

- Visual Appeal: Promotional items like branded koozies rely on vibrant logos; fading undermines marketing ROI.

- Durability Claims: Premium wetsuit brands guarantee season-long performance; UV-induced cracking invalidates warranty and trust.

2. Economic Impacts:

- Return Rates: Products that degrade quickly lead to higher returns—estimated at 8–12% for low-grade neoprene vs. 2–4% for UV-stabilized materials.

- Warranty Costs: Average claim cost per item can reach 15% of retail price; investing in UV resistance reduces overall costs.

3. Environmental Considerations:

- Waste Reduction: Longer-lasting gear means fewer discarded items; reducing landfill contributions.

- Sustainability Goals: Eco-conscious consumers prioritize durable goods; UV stability aligns with sustainable branding.

4. Case Studies:

- Outdoor Envelope: A watersports brand transitioned to dope-dye neoprene, cutting warranty claims by 60% and increasing customer satisfaction scores by 25%.

- Event Marketing: An events agency reported a 40% drop in promotional koozie reorders after upgrading to TiO₂-enhanced neoprene.

Without UV resistance, neoprene goods risk undermining both functional performance and brand integrity. Manufacturers and retailers must view UV additives not as optional extras but as essential investments in product quality, customer loyalty, and environmental responsibility.

How Can You Customize UV-Resistant Neoprene with Szoneier?

Szoneier offers low-MOQ UV-resistant neoprene customization—choose from CR, dope-dye, and fluorine-modified grades, add carbon black, TiO₂, or HALS, and apply silicone coatings. Rapid prototyping (7–10 days) and full OEM/ODM services ensure tailored, UV-stable bags, koozies, gloves, and wetsuits.

Customization bridges technical performance with brand storytelling. Szoneier’s integrated services enable seamless development of UV-stable neoprene goods:

1. Material Selection:

- Consultation: Technical teams guide clients through formulation choices—balancing UV performance, flexibility, and cost.

- Samples: Free small-batch samples (10–20 pieces) of each formulation help brands evaluate UV stability under their specific designs.

2. Additive Integration:

- Bulk Blending: Incorporate carbon black or TiO₂ during compounding for uniform UV protection.

- Surface Treatments: Optional silicone or acrylic lamination layers applied in-house enhance UV barrier properties.

3. Rapid Prototyping & Sampling:

- Timeline: Digital design approval within 2 days; physical sample delivery in 7–10 days.

- Iteration: Up to three free revisions ensure perfect color match and UV additive performance.

4. Full OEM/ODM Production:

- Low MOQ: Production starts at 50 pieces, catering to small brands and test runs.

- Quality Control: ISO 9001 processes, RoHS compliance, and batch testing for UV durability guarantee consistency.

5. Logistics & Support:

- Global Shipping: Sea and air freight options with DDP terms.

- After-Sales: Technical support on product care, field testing, and potential reformulation needs.

Table: Szoneier UV-Resistant Neoprene Offerings

| Feature | Standard Grade | Dope-Dye Grade | Fluoro-Modified Grade |

|---|---|---|---|

| Carbon Black (%) | 0%–3% | 2%–4% | 4%–6% |

| TiO₂ (%) | 0%–2% | 1%–2% | 2%–3% |

| HALS (w/w) | 0%–1% | 1% | 1% |

| Silicone Coating (µm) | 0 | 10–20 | 25–50 |

| MOQ (pcs) | 50 | 50 | 50 |

| Sample Lead Time | 7–10 days | 7–10 days | 7–10 days |

| Production Lead Time | 30–45 days | 30–45 days | 30–45 days |

By aligning technical expertise with flexible manufacturing, Szoneier empowers brands—from startups to established labels—to deliver UV-resilient neoprene products that uphold quality and captivate customers.

What Care Tips Extend UV Protection in Neoprene Products?

Extend UV protection by rinsing neoprene items in fresh water after sun exposure, air-drying in shade, storing in cool, dry places, and reapplying spray-on UV protectants every 3–6 months. Regular inspections for surface chalking and avoiding prolonged direct sunlight when not in use also preserve performance.

Even the most UV-stable neoprene benefits from proper care to maximize service life and appearance:

1. Post-Use Rinse:

- Salt & Chlorine Removal: Rinse thoroughly with fresh water to wash away salt, chlorine, and pollutants that accelerate UV damage.

- Mild Detergent: Use a gentle, neoprene-safe soap if needed; avoid harsh solvents.

2. Drying & Storage:

- Air-Dry in Shade: Direct sunlight can exacerbate UV exposure—dry items in shaded, well-ventilated areas.

- Flat or Hanging Storage: Prevent creases by laying flat or hanging; avoid folding or crushing.

3. Reapplication of UV Protectants:

- Spray Coatings: Use silicone- or acrylic-based UV spray every 3–6 months to replenish surface protection.

- DIY Options: Home gardeners’ UV-protectant sprays (safe for plastics) can be an interim solution.

4. Regular Inspections:

- Surface Checks: Monthly visual inspections for chalking or micro-cracks.

- Functional Tests: Stretch samples to detect any loss of elasticity; replace if performance drops below 80% of original.

5. Storage Environment:

- Temperature Control: Store neoprene goods between 10–25°C to prevent thermal oxidation.

- Moisture Management: Use desiccants or climate-controlled cabinets to deter mold and mildew.

6. Practical Tips:

- Rinse and dry as soon as possible after water-based activities.

- Rotate between multiple products to reduce constant UV exposure on a single item.

Conclusion

Investing in UV resistance for neoprene is not a luxury—it’s a necessity to ensure your products last, perform, and uphold your brand’s reputation. From choosing the right formulation and additives to rigorous testing and proper care, every step enhances durability under the sun.

Ready to create UV-stable neoprene bags, koozies, gloves, or wetsuits that stand out and stand up to the elements? Contact Szoneier today for expert consultation, low-MOQ sampling, and full-service OEM/ODM customization.