Choosing between neoprene and polyester isn’t as simple as it sounds. These two materials dominate categories from bags and sports gear to covers, sleeves, and apparel, yet buyers often struggle to decide which delivers better performance, cost efficiency, and branding potential.

Neoprene offers superior water resistance, insulation, and durability for applications like wetsuits, laptop sleeves, and protective gear, while polyester excels in lightweight breathability, lower cost, and quick-dry performance for apparel, covers, and mass-market bags. The best choice depends on end-use, budget, and sustainability goals.

Imagine sourcing 10,000 custom laptop sleeves. Polyester might slash your budget by 25%, but a neoprene version keeps devices safer in rain-soaked commutes. The right decision blends practical data, material science, and business priorities—and that’s exactly what this guide uncovers. Let’s break it all down so you can choose with confidence.

What Are Neoprene and Polyester, Exactly?

Neoprene is a synthetic rubber offering excellent insulation, flexibility, and water resistance, while polyester is a synthetic polymer known for durability, lightweight structure, and quick-dry performance. Both materials have unique manufacturing processes, densities, and grades affecting cost, comfort, and sustainability.

Before choosing between neoprene and polyester, buyers need to understand their core structure:

| Property | Neoprene | Polyester |

|---|---|---|

| Base Material | Synthetic Rubber (Polychloroprene) | Synthetic Polymer (PET) |

| Density Range | 1.2–1.6 g/cm³ | 1.3–1.4 g/cm³ |

| Water Resistance | Excellent (closed-cell foam) | Moderate (hydrophobic fibers) |

| Stretchability | High | Moderate |

| Thermal Insulation | Excellent | Low |

| Breathability | Low | High |

| Typical Thickness | 1–10 mm | 0.2–1 mm |

| Typical Cost | $3–5/m² | $1–2/m² |

Manufacturing Insights:

- Neoprene originates as liquid polychloroprene, then foamed into sheets. It offers closed-cell insulation, making it a go-to for wetsuits and impact gear.

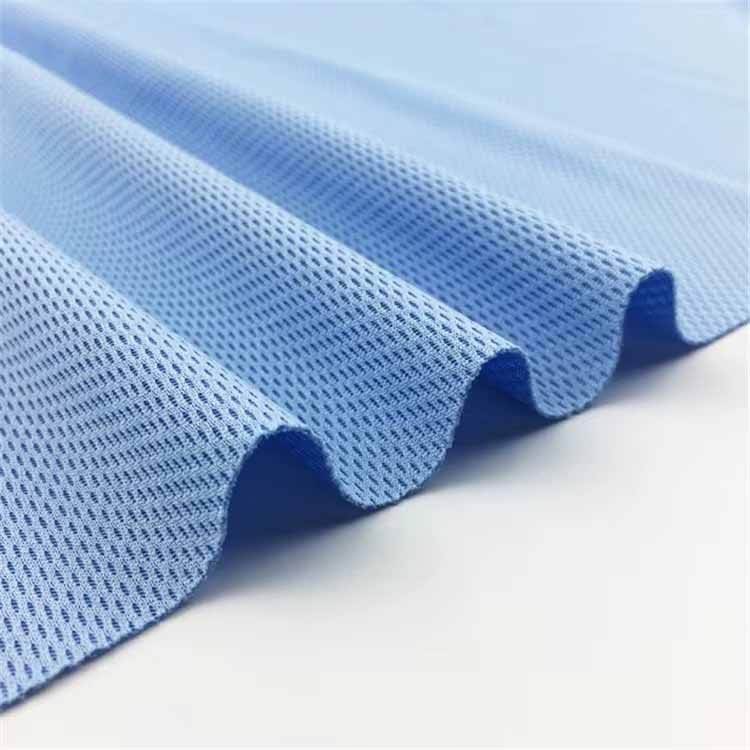

- Polyester is extruded into fibers, woven or knitted into fabrics, with water-repellent finishes often added later for outdoor gear.

Critical Perspective:

- Neoprene’s foam structure provides padding and insulation but adds bulk and cost.

- Polyester’s fiber-based versatility supports lighter, breathable products for mass-market bags, covers, and apparel.

- Sustainability favors recycled polyester (rPET), while eco-neoprene alternatives remain niche due to cost.

For buyers, this means technical specs drive sourcing decisions: choose neoprene for impact resistance and premium feel, polyester for cost efficiency and lightweight performance.

Which Performance Properties Matter Most in Real Use?

Neoprene outperforms polyester in thermal insulation, water resistance, and impact absorption, while polyester offers better breathability, quick-dry performance, and lightweight comfort—making the right choice application-dependent.

| Property | Neoprene Use Cases | Polyester Use Cases |

|---|---|---|

| Thermal Insulation | Wetsuits, laptop sleeves, bottle covers | Jackets, windbreakers, rain covers |

| Water Resistance | Dive gear, marine bags | Umbrellas, outdoor furniture covers |

| Stretchability | Sports braces, gloves | Athletic apparel, tents |

| Breathability | Limited (can trap heat) | High (keeps user cooler) |

| UV Resistance | Moderate | Excellent with coatings |

| Weight | Heavier | Lightweight, portable |

Critical Analysis:

- Neoprene’s closed-cell structure locks out water and retains warmth, ideal for cold, wet environments.

- Polyester’s microfibers enable quick drying, but it lacks natural padding unless laminated with foams.

- In outdoor covers, polyester dominates due to UV coatings and light weight; for protective cases, neoprene shines with cushioning properties.

For example, a neoprene laptop sleeve protects from drops and rain, while a polyester rain cover keeps weight minimal for backpackers. Buyers should analyze end-use environments before deciding.

How Do Neoprene vs. Polyester Compare by Product Category?

Neoprene dominates wetsuits, laptop sleeves, and protective gear where insulation and cushioning matter, while polyester leads in apparel, outdoor covers, and budget-friendly bags due to breathability and cost efficiency.

| Product Type | Recommended Material | Why It Works |

|---|---|---|

| Laptop Sleeves | Neoprene | Shock absorption + water resistance |

| Gym & Travel Bags | Polyester | Lightweight, affordable, quick-dry |

| Wetsuits & Sports Gear | Neoprene | Thermal insulation, flexibility |

| Outdoor Covers | Polyester | UV resistance, weatherproof coatings |

| Bottle Koozies | Neoprene | Keeps drinks cold, insulates well |

| Fashion Backpacks | Polyester | Wide color/texture options |

Buyer Perspective:

- Premium markets lean toward neoprene for its luxury feel and performance.

- Mass retail favors polyester for scalability and pricing flexibility.

- Hybrid designs, like polyester shells with neoprene padding, balance cost and durability.

This hybrid approach often appears in camera bags and sports backpacks, combining polyester’s affordability with neoprene’s shock absorption.

Do Branding, Printing, and Aesthetics Work the Same on Both?

Both materials support branding, but polyester handles sublimation and screen printing better, while neoprene excels with heat-transfer logos and embroidery for premium finishes.

| Printing Method | Neoprene Suitability | Polyester Suitability | Notes |

|---|---|---|---|

| Screen Printing | Good | Excellent | Low cost, simple logos |

| Heat Transfer | Excellent | Good | Vivid colors, small batch customization |

| Sublimation Printing | Limited | Excellent | Best for full-color designs |

| Embroidery | Excellent | Moderate | Premium look, durable branding |

Insights for OEM/ODM Buyers:

- Polyester supports high-volume, full-color graphics for branding-heavy markets like promotional gear.

- Neoprene creates tactile, luxury finishes for upscale products, ideal for corporate gifting or high-end retail.

- Szoneier’s low MOQ and free design support help buyers test multiple branding methods before scaling.

Is Neoprene More Durable Over Time—or Just Different?

Neoprene generally offers longer-lasting performance under water exposure, thermal stress, and impact, while polyester withstands UV, abrasion, and frequent washing better. The right choice depends on environmental stress factors and product lifecycle expectations.

| Durability Factor | Neoprene Performance | Polyester Performance |

|---|---|---|

| Water Resistance | Excellent, no wicking | Moderate, treated finishes help |

| UV Resistance | Moderate, may degrade over years | High with UV coatings |

| Abrasion Resistance | Moderate, foam can tear | Excellent with woven textures |

| Compression Set | Resists deformation under load | Less cushioning over time |

| Chemical Resistance | Good against mild solvents | Strong vs. oils, detergents |

| Odor Retention | May trap smells if not ventilated | Quick-dry, less odor retention |

Are There Cost, MOQ, and Lead-Time Trade-Offs to Expect?

Polyester offers lower cost, faster lead times, and smaller MOQs, while neoprene requires higher investment, longer production cycles, and bulk sourcing for competitive pricing.

| Factor | Neoprene Typical Value | Polyester Typical Value |

|---|---|---|

| Material Cost | $3–5 per m² | $1–2 per m² |

| MOQ (Meters/Color) | 2,000–5,000 | 1,000–2,000 |

| Lead Time | 30–45 days (production only) | 15–25 days |

| Sampling Time | 5–7 days | 2–4 days |

| Shipping Weight | Heavier (foam structure) | Lighter (fiber structure) |

Key Analysis:

- Neoprene: Longer curing cycles, fewer global suppliers, higher freight costs.

- Polyester: Readily available worldwide, supports fast-fashion timelines.

- For SMEs, polyester’s low MOQ reduces upfront capital risk. For premium brands, neoprene’s quality justifies volume-based sourcing.

Szoneier’s low-MOQ customization solves this challenge by offering pilot runs before full-scale production—ideal for startups testing new markets.

Are There Sustainability and Compliance Considerations?

Polyester leads in recycled options (rPET) and global certifications, while neoprene is eco-limited but evolving through innovations like limestone-based and plant-oil neoprene.

| Eco Factor | Neoprene | Polyester |

|---|---|---|

| Recycled Versions | Limited (plant-oil neoprene niche) | Widely available (rPET fabrics) |

| Certifications | OEKO-TEX, REACH possible | OEKO-TEX, GRS, Bluesign common |

| Energy Footprint | Higher curing energy | Lower fiber extrusion energy |

| End-of-Life Options | Difficult to recycle | rPET supports closed-loop use |

Analysis:

- Recycled polyester (rPET) reduces plastic waste, suiting brands with sustainability commitments.

- Eco-neoprene exists but at 2–3× cost, slowing adoption.

- Certifications like OEKO-TEX Standard 100 ensure materials meet global safety and chemical compliance standards—critical for export markets like the EU and US.

Szoneier’s factories comply with ISO9001, OEKO-TEX, and REACH, enabling buyers to meet retailer and government requirements for global distribution.

Which Material Should You Choose for Your Use Case?

Choose neoprene for products needing impact resistance, water protection, and premium feel, and polyester for lightweight, budget-friendly, and breathable designs—or combine both for hybrid performance.

| Use Case | Recommended Material | Reason |

|---|---|---|

| Laptop Sleeves & Electronics | Neoprene | Shock absorption + water resistance |

| Travel & Gym Bags | Polyester | Lightweight, scalable, affordable |

| Outdoor Furniture Covers | Polyester | UV resistance + quick dry |

| Wetsuits & Marine Gear | Neoprene | Thermal insulation + flexibility |

| Fashion Backpacks & Apparel | Polyester or Hybrid | Branding + cost efficiency |

| Premium Corporate Gifts | Neoprene | Luxury feel + durability |

Conclusion: Partner with Szoneier for Custom Neoprene & Polyester Solutions

Choosing between neoprene and polyester requires weighing performance metrics, cost structures, branding goals, and sustainability needs. Both materials excel in different areas—neoprene for premium, protective, and thermal applications; polyester for scalable, affordable, and lightweight solutions.

At Szoneier, we help brands prototype, customize, and scale both materials with:

- Free design support for logos and patterns

- Low-MOQ pilot runs for startups and SMEs

- Certified materials meeting OEKO-TEX, REACH, and ISO standards

- Fast sampling (5–7 days) and short lead times (15–45 days)

Whether you need neoprene bags, polyester covers, or hybrid designs, contact Szoneier today for custom quotes and professional sourcing advice.