If you’ve ever reached for a cold drink at a picnic or outdoor event, you know how quickly it can turn warm in the sun. A reliable can cooler can make all the difference. But how are these handy drink holders made, and what do you need to know to create your own? Let’s dive into the world of can coolers, exploring everything from the materials used to the steps manufacturers take to ensure quality.

What Are Can Coolers?

Can coolers, often called koozies, are insulating sleeves designed to keep your canned drinks cold and refreshing. They slip snugly over standard soda or beer cans, acting as a barrier against external heat. With their lightweight and portable design, can coolers have become a popular accessory at outdoor parties, sporting events, and casual gatherings.

What Are The Key Features Of A Can Cooler?

A good can cooler offers more than just insulation. Key features to consider include:

- Thermal Insulation: The primary function of a can cooler is to keep drinks cold for as long as possible. High-quality materials, such as neoprene, ensure excellent temperature retention.

- Durability: Can coolers should withstand regular use without tearing or losing shape. The material and stitching play a crucial role in ensuring long-lasting performance.

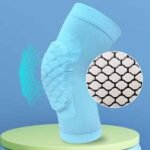

- Grip and Comfort: Many can coolers are designed with a textured or soft exterior for a secure and comfortable grip.

- Portability: Lightweight and collapsible designs make can coolers easy to carry, store, and transport.

- Customization Options: Printing logos, names, or designs on can coolers is a popular way for businesses or individuals to personalize their drink holders.

What Are Can Coolers Made Of?

Can coolers can be made from a variety of materials, each offering unique benefits. Some common materials include:

- Neoprene: A durable, flexible material known for its excellent insulation properties. Neoprene can coolers are popular due to their longevity and ability to maintain a drink’s temperature for extended periods.

- Polyurethane Foam: A lightweight and cost-effective option that provides decent insulation. Foam can coolers are often more affordable and come in a wide range of colors.

- Polyester Fabric: Used for the outer layer of many can coolers, polyester adds a smooth finish and allows for vibrant printing options.

What Material Is Used To Make Koozies?

Neoprene is one of the most commonly used materials for koozies. Its stretchable nature allows it to fit snugly around cans of various sizes, while its insulating properties help maintain the drink’s chill. Neoprene is also water-resistant, making it a practical choice for outdoor events and humid environments. In addition, neoprene is durable and can handle repeated use without losing its shape or effectiveness.

How Do You Design A Custom Can Cooler?

Creating a custom can cooler involves several steps:

- Choose Your Material: Start by selecting a material that meets your insulation and durability requirements. Neoprene is a top choice for most custom projects.

- Decide On The Shape And Size: Determine whether you want a standard-sized can cooler or a custom fit for unique can dimensions.

- Select A Design Or Logo: Use a high-resolution graphic or logo that can be easily printed. Consider the placement and size of the design to ensure it’s visible and aesthetically pleasing.

- Pick A Printing Method: Common options include screen printing, heat transfer, or sublimation. Each method offers different levels of detail, color vibrancy, and cost.

- Order Samples: Before committing to a large batch, create a prototype to ensure the material, fit, and design meet your expectations.

What Equipment Is Needed To Make Can Coolers?

Producing can coolers requires basic equipment and tools:

- Cutting Tools: A cutting die or laser cutter can help achieve precise shapes and sizes.

- Heat Press: For applying printed designs, a heat press ensures consistent results.

- Sewing Machines Or Sealers: To assemble the can coolers, you may need industrial sewing machines or specialized sealing equipment, especially if using neoprene.

- Screen Printing Equipment: If you plan to print logos or patterns, screen printing equipment or a sublimation printer is necessary.

How To Make Can Coolers From Scratch?

Producing a can cooler from scratch may seem challenging, but breaking it down into manageable steps can make the process easier. Here’s how you can go about it:

-

Prepare Your Materials:

- Start by gathering your chosen material, such as neoprene or polyurethane foam.

- Make sure you have a flat, clean surface for cutting and assembling.

- If you’re working with neoprene, ensure it is of adequate thickness (commonly 3mm or more) to provide proper insulation.

-

Measure And Cut:

- Take a standard-sized can and measure its circumference and height. Add a small allowance for seams.

- Cut a rectangular piece of neoprene or foam that matches these dimensions.

- If you’re adding a bottom to your can cooler, cut out a circle that matches the base diameter of the can.

-

Shape The Material:

- Wrap the rectangular piece around the can and mark where the edges meet.

- Trim as needed to ensure a snug fit.

- Be precise—neat edges will make assembly easier and improve the final look.

-

Assemble The Sleeve:

- Use a heat-sealing machine or industrial sewing equipment to join the two sides of the rectangle.

- Ensure the seam is strong and even. If sewing, use a durable thread and stitch pattern that prevents tearing.

-

Attach The Base (Optional):

- Position the circular base piece at the bottom of the sleeve.

- Secure it with a heat press, adhesive, or careful stitching.

- Make sure the base is flush and sturdy.

-

Print Your Design:

- If you want a custom logo or pattern, now’s the time to apply it.

- Use a heat press, sublimation printer, or screen printing equipment to transfer your design onto the surface.

- Ensure the design is positioned correctly and adheres firmly.

-

Quality Check:

- Test the fit by slipping the cooler onto a can. Adjust as needed.

- Inspect all seams and edges for durability.

- Confirm that the cooler maintains the temperature of the can for a reasonable period.

-

Final Touches:

- Clean off any marks or debris.

- Consider adding a finishing edge or trim for a polished look.

- If needed, repeat the process to refine your technique and produce more consistent results.

By following these steps, you can create functional and visually appealing can coolers from scratch, ensuring a custom, high-quality product every time.

How Do Manufacturers Ensure The Quality Of Neoprene Can Coolers?

Quality assurance is a crucial step in producing neoprene can coolers. Manufacturers typically:

- Inspect The Material: Ensure that the neoprene is free from defects, tears, or inconsistencies in thickness.

- Check Seams And Edges: Carefully examine all seams and edges for secure attachment. Weak seams can lead to tearing or reduced insulation performance.

- Test Insulation Properties: Perform tests to confirm that the can cooler maintains the desired temperature for a specific duration.

- Evaluate Printing Quality: Verify that the printed designs are clear, vibrant, and resistant to fading or peeling.

- Conduct Sample Testing: Before mass production, manufacturers often produce a small batch of samples to confirm quality and consistency.

By focusing on these quality checks, manufacturers deliver products that not only look great but also perform reliably.

Conclusion

Creating can coolers involves understanding the materials, tools, and processes that go into producing a high-quality product. By selecting the right material—often neoprene—designing with care, and using reliable equipment, manufacturers can consistently produce can coolers that meet the demands of brands, wholesalers, and retailers. Whether you’re a business looking to offer promotional items or an individual interested in crafting your own drink holders, following these straightforward steps ensures that you’ll end up with can coolers that perform well and look great.

At Szoneier, we specialize in manufacturing high-quality custom can coolers. Our team is here to help you bring your design ideas to life, ensuring your products meet the highest standards. Feel free to reach out to learn more about our services and start creating your own unique can coolers today!