At first glance, putting vinyl on koozies sounds simple. After all, vinyl works on T-shirts, tote bags, and countless DIY projects—so why not koozies? This exact question is searched thousands of times every month by crafters, small businesses, and brands looking to customize drink holders for promotions or resale.

The reality, however, is more complicated.

Koozies are not flat cotton fabric. Most are made from neoprene or foam, materials designed to stretch, insulate, and recover their shape. Vinyl, on the other hand, is relatively rigid once applied. When these two materials meet, the results can vary widely—from clean, durable logos to peeling edges, cracked graphics, or even scorched koozies.

This is why some people swear vinyl works perfectly on koozies, while others say it fails completely. The difference is not luck—it’s material choice, vinyl type, temperature control, and intended use.

For DIY users, understanding these factors prevents wasted time and materials. For brands and bulk buyers, it determines whether vinyl is suitable at all—or whether professional printing methods are the smarter choice.

Yes, you can put vinyl on koozies, but results depend heavily on the koozie material and the type of vinyl used. Heat transfer vinyl can adhere to neoprene koozies when applied at controlled temperatures, while adhesive vinyl often fails. Because neoprene stretches and insulates heat, improper application can cause peeling, cracking, or material damage. For bulk or long-term use, professional printing methods may perform better than vinyl.

What Are Koozies Made Of

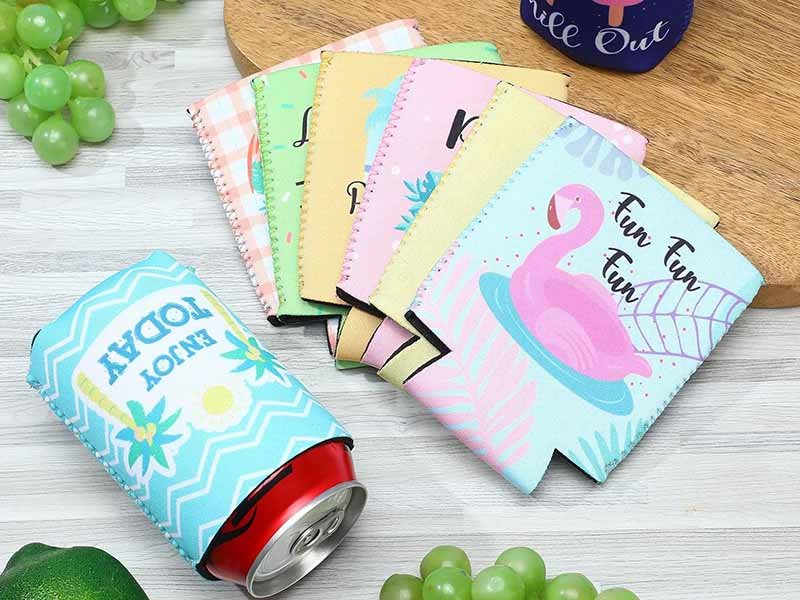

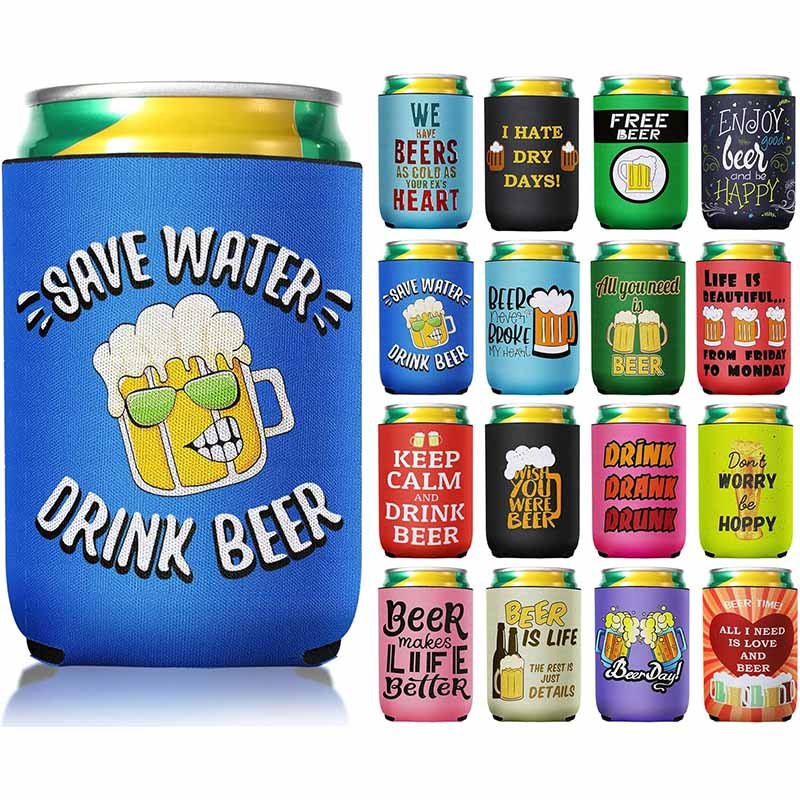

Koozies are most commonly made from neoprene or foam materials designed for insulation and flexibility. Neoprene koozies are durable, stretchy, water-resistant, and reusable, while foam koozies are lightweight, porous, and often disposable. The material choice directly affects insulation performance, comfort, print durability, and whether decoration methods like vinyl or printing will succeed.

At a glance, most koozies look similar. In reality, material choice is the single most important factor influencing how a koozie performs, how long it lasts, and what decoration methods will work.

Understanding koozie materials helps explain why some designs peel, crack, or fade—while others stay intact for years.

What is neoprene, and why is it so common in koozies?

Neoprene is a synthetic rubber originally developed for wetsuits. It is prized for its thermal insulation, flexibility, and durability, which makes it ideal for reusable beverage holders.

Key properties of neoprene koozies include:

- Excellent insulation to keep drinks cold or hot

- Elastic stretch that fits different can and bottle sizes

- Water resistance and resistance to condensation

- Soft, comfortable hand feel

Because neoprene stretches and recovers its shape, it withstands repeated use far better than foam. This is why neoprene koozies are commonly used for branded merchandise, retail products, sports events, and long-term promotional use.

However, neoprene’s elasticity and heat-insulating nature also make customization more technically demanding—especially for vinyl applications.

What types of foam are used in koozies?

Foam koozies are typically made from EVA foam or PU foam. These materials are lightweight, inexpensive, and easy to mass-produce.

Foam koozies are often used for:

- One-time events

- Giveaways

- Large promotional campaigns with tight budgets

Foam provides basic insulation but lacks the durability of neoprene. It compresses easily, does not recover its shape well, and has a porous surface.

From a customization standpoint, foam is less forgiving. The porous texture reduces print clarity, and heat-based decoration methods risk melting or scorching the surface.

Foam koozies are suitable for short-term use—but not for premium or reusable products.

How does koozie material affect insulation performance?

Insulation performance varies significantly by material.

- Neoprene traps air within its rubber structure, slowing heat transfer and maintaining drink temperature longer.

- Foam provides basic insulation but loses effectiveness once compressed or saturated with moisture.

For users, this difference translates into how long a drink stays cold and how comfortable the koozie feels in hand.

For brands, insulation quality affects perceived value. Customers often associate better insulation with higher quality—even if they don’t consciously analyze the material.

How does material choice affect vinyl and printing results?

Material choice directly determines whether vinyl or printing will succeed.

- Neoprene

- Smooth surface allows cleaner prints

- Elastic stretch stresses rigid vinyl

- Heat insulation complicates heat transfer

- Foam

- Porous surface weakens adhesion

- Low heat tolerance limits decoration options

- Compression distorts printed designs

This is why vinyl may appear to work initially but fail after use—especially on neoprene. Printing methods that bond ink into the surface (such as screen printing) perform better across both materials.

In short, decoration problems are often blamed on vinyl—but the real cause is material mismatch.

Are there other materials used for specialty koozies?

Yes, though less common.

Some specialty koozies may use:

- Fabric-covered neoprene for premium aesthetics

- Laminated neoprene for improved print performance

- Recycled neoprene or eco-foam for sustainability-focused brands

These materials require factory-level testing to ensure insulation, durability, and decoration compatibility.

At Oneier, material R&D allows customization beyond standard neoprene thickness and surface treatments—helping brands achieve better results than off-the-shelf options.

Why does material matter so much for buyers and brands?

Because koozies are small products with high use frequency.

Users squeeze them, wash them, stretch them, and expose them to moisture and heat. Any material weakness shows quickly.

For brands, material choice affects:

- Product lifespan

- Customer satisfaction

- Return and complaint rates

- Logo durability and visibility

Choosing the right material is not about cost alone—it’s about matching the product to its real-world use.

Can You Put Vinyl on Koozies

Yes, you can put vinyl on koozies, but results depend heavily on the koozie material, vinyl type, and application method. Heat transfer vinyl can adhere to neoprene koozies under controlled conditions, while adhesive vinyl usually fails. Because koozies stretch and insulate heat, vinyl works best for small DIY projects, not for long-term or commercial use.

Many tutorials say “yes, vinyl works on koozies”. What they usually mean is: vinyl can be made to stick—briefly.

Whether vinyl is a good idea depends on how the koozie is made, how it’s used, and what you expect it to survive.

Why do some people succeed with vinyl on koozies?

Vinyl appears to work when all conditions happen to align:

- The koozie is neoprene with a smooth surface

- A stretch heat transfer vinyl (HTV) is used

- The design is small and placed in a low-stress area

- Heat and pressure are carefully controlled

- The koozie is used lightly

In these cases, vinyl can look clean and professional—at least initially. This is why many DIY users report success after a first test.

However, this success is situational, not universal. Change any variable—larger design, more stretch, colder weather, frequent use—and failure becomes likely.

Why does vinyl fail on koozies so often?

Vinyl fails because vinyl and koozies behave differently under stress.

Koozies—especially neoprene—are designed to:

- Stretch repeatedly

- Recover shape

- Insulate against heat and cold

Vinyl, even stretch HTV, is still a surface layer. When the koozie flexes (for example, when inserting or removing a can), stress concentrates at the vinyl edges. Over time, this leads to:

- Edge lifting

- Cracking

- Peeling

- Premature logo failure

The issue is not user error—it’s material mismatch.

Does vinyl work better on neoprene or foam koozies?

Vinyl works slightly better on neoprene than on foam—but neither is ideal.

- Neoprene

- Smooth surface allows temporary adhesion

- Stretch creates long-term stress

- Heat insulation complicates pressing

- Foam

- Porous surface weakens adhesion

- Low heat tolerance risks melting

- Compression distorts vinyl bonding

On foam koozies, vinyl is usually a short-term novelty solution. On neoprene, vinyl may last longer—but still struggles under real use.

Is vinyl better for DIY projects or commercial orders?

Vinyl is best suited for DIY, hobby, or very small runs.

For example:

- Personal gifts

- One-time events

- Short-term promotional items

For commercial, retail, or bulk orders, vinyl introduces too much risk:

- Inconsistent durability

- Higher complaint rates

- Limited wash and outdoor resistance

This is why professional koozie manufacturers rarely recommend vinyl for large orders, even though it’s popular in DIY communities.

Can vinyl survive washing, condensation, and outdoor use?

This is where most vinyl koozies fail.

Koozies are exposed to:

- Condensation

- Ice water

- Sunlight

- Temperature changes

Water creeps under vinyl edges. UV light makes vinyl brittle. Cold weather reduces vinyl flexibility. Neoprene continues to flex underneath.

The result: vinyl that looks fine on day one often fails weeks later.

When does vinyl make sense on koozies?

Vinyl makes sense only when expectations are realistic.

It can be acceptable if:

- Durability is not critical

- The design is small and simple

- The koozie will not be washed frequently

- The project is experimental or personal

Vinyl should not be treated as a “default” decoration method for koozies—it is a conditional workaround.

What do manufacturers recommend instead of vinyl?

Most experienced factories recommend printing methods that bond into the material, not sit on top of it.

These include:

- Screen printing

- Professional heat transfer printing

- Sublimation (for specific materials)

These methods stretch with neoprene, resist moisture, and hold up to repeated use far better than vinyl.

Which Vinyl Types Work Best on Koozies

The best vinyl for koozies is stretch heat transfer vinyl (HTV) designed for flexible fabrics. Standard adhesive vinyl is not recommended, and regular HTV often fails on neoprene. Even stretch HTV has durability limits due to koozie elasticity and moisture exposure, making vinyl more suitable for small DIY projects than commercial production.

When people say “vinyl works on koozies,” they rarely explain which vinyl or under what conditions. This is the root of most confusion.

Koozies—especially neoprene koozies—are stretchable, insulating, and moisture-exposed products. Most vinyl types were never designed for that environment.

Below is a clear, experience-based breakdown of vinyl options and how they actually perform.

What kind of vinyl do you use on koozies?

For koozies, only heat transfer vinyl (HTV) should even be considered—and only specific types.

Acceptable vinyl characteristics include:

- Designed for stretch fabrics

- Thin and flexible film

- Low-temperature adhesive activation

- Matte or soft-touch finish (gloss cracks faster)

Even with these features, vinyl performance is conditional. It can look good initially but still fail under repeated use.

Permanent adhesive vinyl, despite its name, is not suitable for koozies. It relies on surface adhesion only and does not bond chemically with neoprene or foam.

Why does stretch heat transfer vinyl work better than regular HTV?

Regular HTV is made for cotton or polyester garments that stretch minimally. Neoprene stretches far more aggressively.

Stretch HTV is formulated with elastic polymers that allow limited elongation without cracking. This makes it more compatible with koozies—but not immune to failure.

Key advantages:

- Better edge flexibility

- Reduced cracking during light stretch

- Cleaner look on curved surfaces

Key limitation:

- Still weaker than ink-based printing under repeated stress

Stretch HTV buys you time, not permanence.

Can you use standard Cricut vinyl on koozies?

This is one of the most searched questions—and the most misunderstood.

- Cricut adhesive vinyl: Not recommended

- Cricut regular HTV: High failure risk

- Cricut stretch HTV: Best Cricut option, still limited

Cricut machines are cutting tools, not material validators. Just because Cricut vinyl cuts cleanly does not mean it performs well on neoprene.

DIY users often succeed on their first test koozie, then experience peeling after real use. This leads to false confidence.

Why is adhesive vinyl risky on koozies?

Adhesive vinyl fails for three reasons:

- Surface mismatch Neoprene and foam have low surface energy. Adhesives don’t grip well.

- Moisture exposure Condensation weakens pressure-sensitive adhesives quickly.

- Flex stress Adhesive vinyl cannot stretch with the koozie, causing edge lift.

Adhesive vinyl may stick temporarily—but it is not designed for reusable drinkware.

Are specialty vinyls better for neoprene?

Some specialty vinyls perform slightly better, including:

- Silicone-based HTV

- Ultra-thin elastic HTV

- Low-temp athletic vinyl

These options improve flexibility and reduce scorching risk. However, they also:

- Increase material cost

- Require precise application

- Still underperform compared to printing

For commercial buyers, specialty vinyl often costs more without delivering production-grade durability.

How does vinyl thickness affect performance on koozies?

Thickness matters more than brand.

- Thick vinyl

- Cracks faster

- Lifts at edges

- Feels stiff on neoprene

- Thin vinyl

- Flexes better

- Looks more integrated

- Still limited by stretch and moisture

When vinyl is used at all, thinner is always safer.

When is vinyl actually a reasonable choice?

Vinyl makes sense only when:

- The project is DIY or personal

- The design is small and simple

- Stretch areas are avoided

- Long-term durability is not required

For:

- Retail sales

- Brand merchandise

- Outdoor events

- Reusable premium koozies

Vinyl is not the right tool.

Why do manufacturers discourage vinyl for bulk koozies?

From a factory perspective, vinyl introduces:

- Inconsistent results

- Higher complaint rates

- Difficulty in quality control

- Increased rework or returns

Printing methods bond into neoprene and move with it. Vinyl sits on top and fights the material.

How Do You Apply Vinyl to Koozies Correctly

To apply vinyl to koozies correctly, use stretch heat transfer vinyl (HTV), keep the koozie clean and dry, and apply controlled heat with even pressure using a heat press or mini press. Avoid overheating neoprene or foam, use short test presses, and let the adhesive fully bond before peeling the carrier sheet. Cricut can cut the vinyl, but proper application still depends on temperature, pressure, and timing.

Applying vinyl to koozies isn’t the same as applying vinyl to cotton shirts. Koozies are insulating, flexible, and often curved, which means heat and pressure behave differently.

Below is the most reliable process for DIY and small-run production—plus the “why” behind each step.

Can you use a Cricut on koozies?

Yes—but only for cutting the vinyl design, not applying it.

A Cricut machine is perfect for:

- Cutting HTV shapes and letters

- Creating layered designs

- Making consistent logos for small batches

But Cricut does not solve the hard part, which is bonding vinyl to neoprene or foam correctly. To apply vinyl, you still need:

- A heat press, mini press, or iron

- Controlled heat and pressure

- Correct pressing time

If you’re doing more than a few pieces, a heat press is strongly recommended because irons create uneven heat and pressure—one of the biggest causes of peeling.

How should the koozie surface be prepared?

Surface prep is simple, but it determines whether the vinyl bonds evenly.

Do this every time:

- Clean the surface

- Remove dust, oils, or residue from handling

- A clean dry cloth is usually enough; avoid harsh solvents on neoprene

- Dry completely

- Moisture trapped on the surface weakens the adhesive layer

- Pre-press briefly (a quick warm-up press)

- This removes surface moisture and flattens the surface

- It also helps stabilize the area where the vinyl will sit

Important: don’t stretch the koozie flat aggressively when preparing it—stretching changes how it rebounds later and can cause the vinyl to crack once released.

What temperature and pressure are required?

This is where most koozie vinyl projects fail.

Koozies are not fabric—they trap heat. That means you typically need:

- Lower temperatures than garment settings

- Controlled pressure (firm but not crushing)

Why lower heat matters:

- Neoprene can scorch, shine, or warp

- Foam can melt or compress permanently

- Excess heat can damage the koozie before the adhesive properly activates

Pressure matters because:

- Too little pressure → weak bonding → peeling edges

- Too much pressure → compresses neoprene/foam → uneven bonding and texture distortion

Best practice: follow the vinyl manufacturer’s HTV range, then test slightly lower first and adjust gradually.

How long should vinyl be pressed to avoid damage?

Long presses are risky on koozies. A safer approach is short, controlled presses.

Why:

- Neoprene’s insulation makes surface temperatures rise quickly

- Overheating causes cosmetic damage even if the vinyl “sticks”

A reliable technique is:

- Press for a shorter time

- Check bonding edges

- Re-press briefly if needed

This method reduces scorching while still allowing adhesive activation.

Also, allow the koozie to cool and stabilize before heavy handling. A design may look bonded immediately but fail after flexing if the adhesive hasn’t fully set.

How do you place the vinyl so it doesn’t peel later?

Placement affects durability more than many people realize.

To reduce peeling risk:

- Keep designs centered on a flatter area

- Avoid edges near seams or heavy curvature

- Avoid high-stretch zones where the koozie expands most during use

- Use rounded corners instead of sharp corners (sharp corners lift first)

Large solid vinyl panels are the most likely to fail. Smaller logos and simpler shapes survive longer.

If durability is important, design choices matter as much as pressing technique.

How do you peel the carrier sheet correctly?

Incorrect peeling is a common cause of “it stuck, then lifted.”

Follow these rules:

- If your vinyl is cold peel, wait until fully cool

- If it’s warm peel, peel slowly while warm

- Peel at a low angle (close to the surface), not straight up

If any edge lifts during peeling:

- Lay the carrier back down

- Press again briefly

- Then peel again slowly

Ripping the carrier quickly often pulls up edges that were not fully bonded.

How can you test durability before making many koozies?

Testing prevents wasted materials and inconsistent batches.

A simple durability test:

- Let the koozie rest after pressing

- Insert and remove a can/bottle repeatedly

- Flex the neoprene around the design area

- Observe edge lifting and cracking

- Light wipe test to simulate moisture exposure

If the design fails in basic testing, it will fail faster in real use—especially outdoors.

Brands should always validate the method on samples before scaling.

What Are the Common Problems When Putting Vinyl on Koozies

The most common problems when putting vinyl on koozies include peeling edges, cracking after stretching, scorching from excess heat, weak adhesion due to moisture, and poor durability after washing. These issues occur because koozies—especially neoprene—are flexible, heat-insulating materials that do not bond naturally with rigid vinyl. Even correct application cannot fully eliminate these risks.

Many people assume vinyl problems come from poor technique. In reality, most issues are structural and material-based, not user mistakes.

Below are the most common problems users and brands encounter—explained clearly and honestly.

Why does vinyl peel or lift at the edges?

Edge lifting is the number-one complaint.

This happens because koozies constantly expand and contract. Every time a can or bottle is inserted, the neoprene stretches outward. Vinyl, even stretch HTV, resists this movement.

Stress concentrates first at the edges and corners. Over time, this causes:

- Corners to lift

- Edges to curl

- Adhesive bond to weaken

Large vinyl designs fail faster than small ones because more surface area is resisting stretch. Sharp angles fail faster than rounded shapes.

This is not a pressing error—it’s a physics issue.

Why does vinyl crack after a short time?

Cracking occurs when vinyl cannot stretch at the same rate as the koozie.

Neoprene is engineered to stretch repeatedly and recover. Vinyl is a surface layer that stretches only within a limited range. When that limit is exceeded, micro-cracks form. These cracks may not be visible immediately, but they grow with each use.

Cold weather makes this worse. Vinyl becomes stiffer in low temperatures, while neoprene still flexes.

This is why a koozie that looks fine indoors can fail quickly outdoors.

What causes scorching, melting, or shine marks?

Heat damage is extremely common and often irreversible.

Koozies—especially neoprene—trap heat. When pressing vinyl:

- Surface temperature rises quickly

- The inside of the material heats more slowly

As a result, users often apply more heat than needed, causing:

- Burn or shine marks

- Warping or shrinking

- Loss of elasticity

Foam koozies are even more vulnerable, as foam can melt or permanently compress before the vinyl adhesive activates.

Ironically, overheating often damages the koozie before the vinyl fully bonds.

Why does vinyl fail after washing or getting wet?

Moisture is a hidden enemy of vinyl on koozies.

Koozies are constantly exposed to:

- Condensation

- Ice water

- Humidity

Water seeps into microscopic gaps along vinyl edges, weakening the adhesive layer. Repeated wetting and drying cycles accelerate edge lifting and peeling.

Even hand washing can shorten vinyl lifespan. Machine washing almost guarantees failure.

Vinyl is not designed for reusable drinkware environments.

How does stretching during use damage vinyl?

Stretch damage doesn’t happen all at once—it accumulates.

Each stretch cycle slightly weakens the adhesive bond. Over time, this leads to:

- Loss of elasticity in the vinyl

- Visible cracking

- Full separation from the surface

High-stretch zones—such as the center of the koozie body—experience the most stress. Designs placed in these areas fail faster than designs placed on flatter, less flexible zones.

Why do some vinyl koozies look fine at first but fail later?

This is one of the most misleading aspects of vinyl.

Vinyl can appear fully bonded immediately after pressing. The adhesive may feel secure, and edges may look clean.

However:

- Adhesive curing continues after pressing

- Stress exposure reveals weak bonding

- Environmental conditions accelerate failure

What looks like a success on day one often becomes a problem after real-world use.

This delayed failure is why vinyl is risky for customer-facing products.

Can these problems be completely avoided?

Not entirely.

You can reduce risk by:

- Using stretch HTV

- Keeping designs small

- Avoiding high-stretch zones

- Controlling heat carefully

But you cannot eliminate the fundamental mismatch between vinyl and koozie materials.

That’s why professional manufacturers treat vinyl as a conditional option, not a standard solution.

Are Vinyl-Printed Koozies Durable for Real Use

Vinyl-printed koozies are generally not durable enough for real-world, long-term use. While they may look good initially and work for short-term or DIY projects, vinyl designs often crack, peel, or lift after repeated stretching, washing, or outdoor exposure. For reusable, retail, or promotional koozies, professional printing methods offer far better durability than vinyl.

Durability isn’t about how a koozie looks right after pressing. It’s about what happens after weeks or months of real use.

Koozies are handled, stretched, squeezed, washed, and exposed to moisture and temperature changes. These conditions reveal vinyl’s limitations quickly.

How do vinyl koozies perform after repeated use?

Repeated use is where vinyl struggles the most.

Every time a can or bottle is inserted, the koozie stretches outward. Vinyl resists this movement, placing stress along its edges. Over time, this causes:

- Micro-cracking

- Edge lifting

- Loss of adhesion

Even stretch HTV cannot fully keep up with neoprene’s elasticity. What begins as minor edge wear eventually becomes visible peeling.

This wear pattern is consistent across DIY projects and factory tests.

What happens to vinyl koozies in outdoor environments?

Outdoor use accelerates failure.

Vinyl reacts strongly to temperature changes:

- In cold conditions, vinyl stiffens and cracks more easily

- In hot conditions, adhesive softens and loses grip

UV exposure further degrades vinyl, making it brittle over time. Meanwhile, neoprene continues to flex normally.

This mismatch causes vinyl designs to fail faster outdoors than indoors—especially at sports events, beaches, and tailgates.

Do vinyl koozies survive washing and moisture?

Washing is a major durability test—and one vinyl rarely passes well.

Condensation from cold drinks introduces constant moisture. Water penetrates tiny gaps along vinyl edges, weakening the adhesive bond.

Even gentle hand washing can:

- Lift edges

- Reduce adhesion

- Shorten design lifespan

Machine washing almost guarantees peeling or cracking.

Because koozies are reusable and frequently wet, vinyl is poorly suited for this product category.

How long do vinyl-printed koozies typically last?

Lifespan varies, but patterns are clear:

- Short-term / decorative use: acceptable

- Weeks to months of light use: visible wear

- Frequent use or outdoor exposure: rapid failure

Vinyl durability on koozies is measured in uses, not years. For products expected to represent a brand over time, this is a critical limitation.

Are vinyl koozies acceptable for promotions or resale?

It depends on expectations.

Vinyl may be acceptable for:

- One-time events

- Personal gifts

- Low-risk giveaways

Vinyl is not ideal for:

- Retail sales

- Brand merchandise

- Reusable promotional products

Customer dissatisfaction often stems from vinyl failing sooner than expected—even if the product looked good initially.

Why do manufacturers avoid vinyl for production orders?

From a manufacturing perspective, vinyl introduces:

- Inconsistent results

- Higher quality control risk

- More customer complaints

- Increased returns or rework

Printing methods that bond ink into neoprene stretch naturally with the material and last far longer. This is why experienced factories rarely recommend vinyl for bulk koozie orders.

What Are Better Alternatives to Vinyl on Koozies

Better alternatives to vinyl on koozies include screen printing, professional heat transfer printing, and sublimation (for compatible materials). These methods bond more effectively with neoprene or foam, stretch with the material, and provide superior durability against washing, moisture, and outdoor use. For commercial, retail, or reusable koozies, manufacturers strongly prefer these methods over vinyl.

Vinyl sits on top of the koozie. Professional printing methods work with the koozie material.

That single difference explains why alternatives consistently outperform vinyl in real use.

Below are the most reliable options used by experienced koozie manufacturers—and why they work.

Why is screen printing the most common alternative?

Screen printing is the industry standard for neoprene koozies.

Instead of forming a surface layer, specially formulated inks penetrate and bond with the neoprene surface. This allows the printed area to flex naturally as the koozie stretches.

Key advantages:

- Excellent stretch tolerance

- Strong resistance to peeling and cracking

- Good performance in wet and outdoor conditions

- Cost-effective for medium to large quantities

Screen printing also produces a clean, professional look that customers associate with quality merchandise.

For most reusable neoprene koozies, screen printing offers the best balance of durability, appearance, and scalability.

How does professional heat transfer printing differ from vinyl?

Heat transfer printing is often confused with vinyl—but they are not the same.

Unlike HTV vinyl, professional heat transfer prints use printed transfer sheets that distribute stress evenly across the design. The ink layer is thinner and more flexible than vinyl film.

Benefits include:

- Better stretch compatibility than vinyl

- Cleaner edges and finer detail

- Improved wash resistance

- More consistent results in production

This method is especially useful for:

- Multi-color designs

- Gradients

- Small-to-medium production runs

Heat transfer printing bridges the gap between vinyl convenience and screen printing durability.

When does sublimation work for koozies?

Sublimation works only on specific materials.

It requires:

- Polyester-coated surfaces

- Light-colored or white bases

When compatible, sublimation creates a dye-level bond—the design becomes part of the material itself. This means:

- No cracking

- No peeling

- Excellent wash and fade resistance

However, standard neoprene is not naturally sublimation-ready. Sublimation is typically used on fabric-covered neoprene or specially treated surfaces.

This method is ideal for full-color, photo-quality designs—when material conditions allow.

How do these alternatives handle stretching and real use?

This is where vinyl falls behind.

- Screen printing stretches with neoprene

- Heat transfer printing distributes stress evenly

- Sublimation becomes part of the surface

All three outperform vinyl under:

- Repeated can insertion

- Moisture exposure

- Washing

- Outdoor temperature changes

They are designed for reusable products, not temporary decoration.

Which method is best for different use cases?

Different needs require different solutions:

- Bulk promotional koozies → Screen printing

- Detailed or multi-color logos → Heat transfer printing

- Photo or full-coverage designs → Sublimation (if material allows)

- DIY or very small runs → Vinyl (with limitations)

Understanding the end use prevents choosing a method that fails prematurely.

Why do manufacturers discourage vinyl for production?

From a factory perspective, vinyl introduces:

- Inconsistent durability

- Higher quality control risk

- More customer complaints

- Increased returns or remakes

Professional printing methods are easier to standardize, test, and scale. They reduce risk for both the manufacturer and the brand.

How does choosing the right alternative protect your brand?

Koozies are small items—but they are high-touch brand assets.

When logos peel or crack:

- Customers notice

- Perceived brand quality drops

- Trust erodes

Choosing a durable printing method ensures the koozie continues to represent your brand positively throughout its usable life.

What Should Buyers Know Before Customizing Vinyl Koozies

Before customizing vinyl koozies, buyers should understand that vinyl is best suited for small DIY or short-term projects, not long-term or commercial use. Material compatibility, design size, stretch zones, moisture exposure, and expected lifespan all affect success. For bulk orders or reusable koozies, professional printing methods usually deliver better durability and lower risk than vinyl.

From a buyer’s perspective, vinyl koozies seem attractive: low setup cost, fast turnaround, and flexibility for small orders. However, vinyl adds hidden risks that many buyers only discover after products reach customers.

Understanding these factors before ordering saves time, money, and reputation.

What is the biggest misconception buyers have about vinyl koozies?

The most common misconception is assuming vinyl behaves like printed ink.

Many buyers believe:

- If vinyl sticks once, it will last

- Stretch HTV guarantees durability

- A good first sample equals production success

In reality, vinyl is a surface film. It does not integrate with neoprene or foam. Stretch, moisture, and temperature changes gradually weaken the bond—even if the first sample looks perfect.

Buyers should judge vinyl not by appearance on day one, but by performance after weeks of use.

How does intended use affect whether vinyl is appropriate?

Intended use should guide the decoration method.

Vinyl may be acceptable for:

- One-time events

- Personal gifts

- Short-term promotions

Vinyl is risky for:

- Retail products

- Brand merchandise

- Reusable drinkware

- Outdoor or sports events

If customers are expected to reuse, wash, or take koozies outdoors, vinyl failure becomes likely. Buyers must align decoration choice with how the product will actually be used—not how it looks on a shelf.

How do design choices impact vinyl performance?

Design matters more with vinyl than with printing.

High-risk design features include:

- Large solid vinyl areas

- Sharp corners and thin strokes

- Placement on high-stretch zones

Safer vinyl designs are:

- Small logos

- Rounded shapes

- Centered on flatter areas

Buyers who push complex or oversized designs often experience faster peeling and cracking—even with stretch HTV.

How do MOQ and scale change the vinyl decision?

Vinyl can seem cost-effective at very low quantities, but scale changes the equation.

At small volumes:

- Vinyl may reduce setup costs

- DIY or semi-manual application is feasible

At larger volumes:

- Inconsistency increases

- Labor cost rises

- Quality control becomes difficult

- Complaint risk multiplies

For bulk orders, screen printing or professional heat transfer printing is often cheaper per unit and far more reliable than vinyl.

What quality risks should buyers plan for?

Vinyl introduces several quality risks buyers should anticipate:

- Variation between units

- Edge lifting after shipping

- Early wear complaints

- Higher return or replacement rates

These issues are harder to detect during pre-shipment inspection because vinyl often fails after real use begins.

Experienced manufacturers flag these risks early—but buyers must be willing to consider alternatives.

Why does supplier experience matter so much with vinyl koozies?

Not all factories understand neoprene behavior.

A factory with neoprene R&D experience can:

- Predict vinyl failure points

- Recommend safer design adjustments

- Suggest alternative decoration methods

- Run real-world stress testing

When should buyers choose printing instead of vinyl?

Buyers should choose printing when:

- Durability matters

- The product is reusable

- The brand reputation is involved

- Orders are medium to large volume

Printing methods bond with the material and stretch naturally with neoprene—delivering consistent results across batches.

Vinyl should be a deliberate choice, not a default.

How Can Oneier Help Customize Neoprene Koozies

Oneier helps customize neoprene koozies by combining in-house neoprene material R&D, decoration testing, and OEM/ODM manufacturing expertise. Instead of simply applying vinyl, Oneier evaluates material thickness, stretch behavior, and end use to recommend durable printing methods, optimize designs, and deliver consistent quality with low MOQ, fast sampling, and reliable lead times.

Many suppliers can make koozies. Very few understand how neoprene behaves after months of real use.

That difference defines Oneier’s role in customization.

How does Oneier’s neoprene expertise improve koozie quality?

Oneier is not just a koozie assembler—it is a neoprene-focused manufacturer.

With over 18 years of experience in neoprene material R&D and product development, Oneier understands:

- Stretch ratios under repeated use

- Heat tolerance limits during decoration

- How thickness affects insulation and logo durability

This knowledge allows Oneier to adjust neoprene density, lamination, and surface treatment before decoration, which directly improves final product performance.

How does Oneier test vinyl and printing compatibility?

Before approving any decoration method, Oneier runs material-specific tests, including:

- Stretch-and-recovery testing

- Edge adhesion checks

- Heat tolerance trials

- Moisture and condensation exposure

If vinyl is requested, Oneier evaluates whether it will realistically survive the intended use. In many cases, Oneier proactively recommends screen printing or professional heat transfer printing instead—saving buyers from future complaints.

This consultative approach reduces hidden risk.

What decoration options can Oneier provide besides vinyl?

Oneier supports multiple production-grade decoration methods for neoprene koozies, including:

- Screen printing for durability and scalability

- Professional heat transfer printing for detail and flexibility

- Embossed or debossed logos for premium branding

- Sewn labels or patches for long-term use

Each method is matched to use case, quantity, and budget, not chosen by habit.

How does Oneier support low MOQ and fast sampling?

Oneier is structured to serve both small-to-mid buyers and premium brands.

Buyers benefit from:

- Low MOQ for testing and market validation

- Free design support and artwork adjustment

- Rapid prototyping to validate decoration choice

- Sample testing before mass production

This flexibility is especially valuable for brands experimenting with koozies as promotional or retail items.

How does Oneier ensure consistency in bulk production?

Consistency is one of the biggest challenges in koozie customization.

Oneier controls:

- Neoprene sourcing and cutting

- Lamination and surface treatment

- Decoration parameters

- Final QC and packaging

By managing these steps in-house or through long-term partner facilities, Oneier minimizes batch variation—one of the main reasons vinyl-based koozies fail at scale.

How does Oneier help buyers avoid common koozie mistakes?

Oneier’s role goes beyond production.

The team actively helps buyers:

- Avoid oversized or high-risk vinyl designs

- Choose decoration methods aligned with real use

- Balance cost, durability, and brand perception

- Prevent redesigns after market feedback

This guidance is especially valuable for buyers new to neoprene products.

What types of buyers work best with Oneier?

Oneier typically works with:

- Overseas small and mid-sized buyers

- Promotional product companies

- E-commerce brands

- Sports, beverage, and lifestyle brands

These buyers value honest recommendations, not just execution.

Conclusion

Choose the Right Method—Not Just the Easy One

So, can you put vinyl on koozies? Yes—but knowing when not to is just as important.

For DIY projects, vinyl can work with care. For brands, promotions, and retail products, professional printing methods are safer, more durable, and more cost-effective.

If you’re planning to customize neoprene koozies—or any neoprene products such as bags, koozies, sports or medical supports—Oneier is ready to help.

Contact Oneier today to discuss your project and choose a customization method that actually lasts—not just one that looks good on day one.

Good customization isn’t about shortcuts. It’s about choosing the right process from the start.