Neoprene is everywhere—from the sleek sleeves that cradle your laptop to the cozy covers keeping beverages cold. Yet with millions of pounds of neoprene entering landfills each year, the question isn’t just “what can we make with it?” but “what happens after we’re done?”

Neoprene can be recycled through both mechanical and chemical processes, diverting waste from landfills and recovering valuable polymer chains for reuse. By breaking down scrap neoprene into reusable feedstock, manufacturers can slash raw‐material costs by up to 30% and reduce greenhouse gas emissions by 25%, while still delivering the performance B2B buyers demand.

Imagine a wetsuit that not only keeps you warm in icy waters but, at end of life, reemerges as a high-performance laptop sleeve—without ever touching a landfill. That’s the circular future awaiting neoprene, and it starts now.

Why Is the Recyclability of Neoprene So Important?

Neoprene’s ubiquity in industrial and consumer goods—bags, koozies, gaskets, wetsuits—means disposal volumes exceed 100 million pounds annually in North America alone. Unrecycled scrap ends up clogging landfills and releasing toxins when incinerated. Recycling neoprene conserves nonrenewable petrochemicals, cuts production energy by up to 40%, and helps brands hit ESG targets—crucial for B2B buyers increasingly scrutinizing supply-chain sustainability.

Neoprene is a synthetic rubber derived primarily from chloroprene, a petrochemical byproduct. Its exceptional durability and flexibility make it ideal for protective gear and custom promotional items. However, those same chemical bonds that give neoprene resilience also render it resistant to natural degradation. Left unchecked, end-of-life neoprene can persist in the environment for centuries.

Landfilling neoprene not only occupies valuable space but risks leachate that can contaminate soil and groundwater. Worse yet, incineration—sometimes pursued to recover energy—releases hydrochloric acid and dioxins unless scrupulously managed. For corporate buyers, these environmental liabilities translate into reputational and regulatory risks that can impact customer relationships and market access.

By contrast, a closed-loop or circular neoprene supply chain transforms what was once waste into feedstock. Every pound of recycled neoprene reduces demand for virgin chloroprene, conserves up to 50 MJ of energy per kilogram, and cuts CO₂ emissions by nearly one kilogram. In an era when sustainability metrics can make or break multimillion-dollar contracts, recyclable neoprene is not merely “nice to have”—it’s a strategic imperative.

How Is Neoprene Manufactured and Which Materials Are Used?

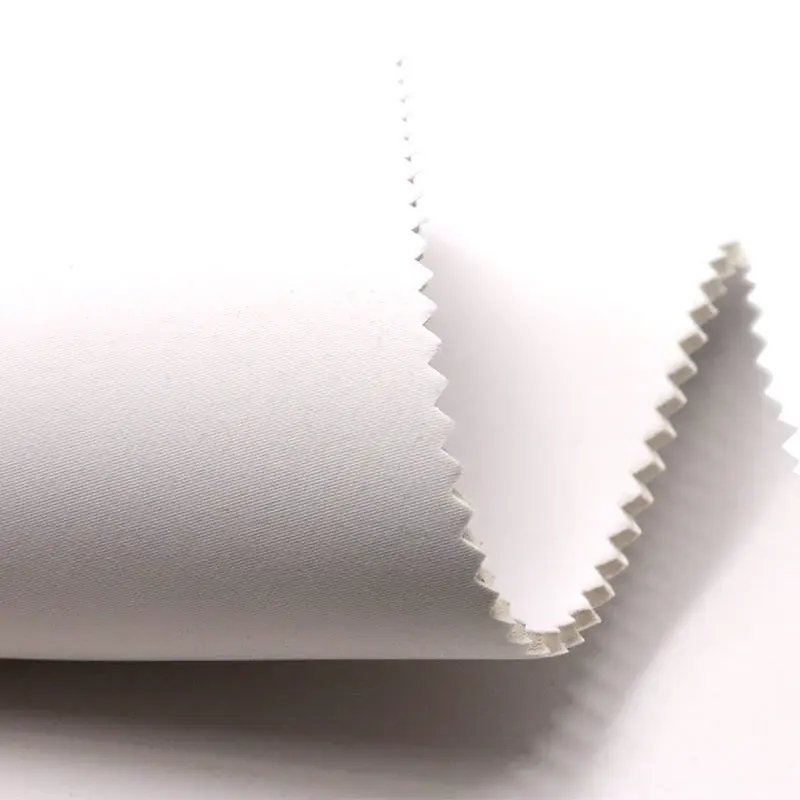

Neoprene production starts with polymerizing chloroprene monomers, often blended with fillers (carbon black, silica), stabilizers (antioxidants), and plasticizers to tune flexibility. Fabrics are then laminated to neoprene sheets or foams using adhesives and coatings. These additives and multilayers enhance performance but complicate recycling—adhesives may need removal, and mixed polymers demand specialized processing.

- Polymerization & Base Formulation

- Chloroprene Monomer (CR): The backbone; polymerized via emulsion or mass processes.

- Fillers: Carbon black for UV stability and tensile strength; silica for heat resistance.

- Plasticizers & Stabilizers: Phthalates or bio-based esters to adjust softness; antioxidants to prevent oxidative breakdown.

- Fabric Lamination & Coating

- Knit or Woven Face Material: Nylon, polyester, or specialty textiles laminated on one or both sides for abrasion resistance.

- Adhesive Layers: Solvent-based or waterborne adhesives bond fabric to rubber.

- Surface Treatments: PU or PVC coatings can add waterproofing or color—but create mixed materials.

- Impact on Recyclability

- Multilayer Complexity: Mechanical recycling demands delamination; chemical recycling must handle diverse chemistries.

- Contaminants: Metal eyelets, velcro, zippers in finished goods must be removed pre-processing.

- Additive Variability: Plasticizer and stabilizer types dictate chemical routes (e.g., hydrolysis vs. pyrolysis).

| Component | Function | Recycling Challenge |

|---|---|---|

| Carbon Black | UV Stability, Strength | Impurities in melt byproducts |

| Fabric Laminate | Abrasion Resistance | Delamination required |

| Solvent-Based Adhesive | Bonding | VOC emissions during thermal melt |

| Plasticizers | Flexibility | Chemical route optimization needed |

Understanding these ingredients helps B2B buyers specify grades that maximize both performance and recyclability—ensuring that products can flow back into the circular pipeline rather than the waste stream.

Can Neoprene Truly Be Recycled? Insights into Current Methods

Yes—neoprene can undergo mechanical recycling (shredding and re-melting) or chemical recycling (devulcanization, pyrolysis). Mechanical methods yield lower‐grade crumb rubber for non–load-bearing applications, while chemical processes recover near‐virgin polymer chains. A handful of commercial facilities worldwide offer pilot and scale‐up programs, but feedstock purity and economics remain hurdles for small OEM orders.

1. Mechanical Recycling

- Process: Scrap neoprene is granulated, washed, and extruded into new sheets or molded parts.

- Applications: Floor mats, industrial gaskets, low‐stress cases.

- Limitations: Recycled polymer has shortened chain lengths; mechanical properties degrade (tensile strength drops ~15%).

2. Chemical Recycling

- Devulcanization: Uses heat, pressure, and catalysts (e.g., alkanolamines) to break sulfur crosslinks.

- Pyrolysis: Thermally decomposes neoprene under inert atmosphere into oils and monomers.

- Outcome: Recovered chloroprene oligomers can be re‐polymerized to near‐virgin quality.

- Drawbacks: High energy input; specialized reactors; potential emissions control.

3. Emerging Hybrid Approaches

- Solvolysis: Combines solvents and catalysts at moderate temperatures to cleave bonds selectively.

- Bio‐Catalytic Routes: Experimental enzymes or microbes that can partially degrade synthetic rubbers.

Despite technical feasibility, today’s recycled neoprene volumes represent less than 5% of total production. Scaling these methods requires coordinated take-back programs, standardized feedstock specs, and investment in modular recycling units near manufacturing hubs.

Which Technologies and Facilities Accept Neoprene for Recycling?

Leading-edge facilities in Europe, Japan, and North America use devulcanization, pyrolysis, and solvolysis to recycle neoprene. Examples include Lehigh Technologies (USA), Kreussler (Germany), and Teijin (Japan). These partners accept clean, delaminated scrap—often only in bulk (>500 kg)—and return crumb rubber or re-polymerized feedstock. Capacity constraints and logistics make direct recycling challenging for small-batch custom orders, but networked consolidation hubs and freight‐optimized LCL shipments offer solutions.

- Lehigh Technologies (USA)

- Method: Cryogenic grinding plus devulcanization.

- Output: High‐performance micronized crumb rubber for automotive and footwear.

- Min. Batch: ≥1,000 kg.

- Kreussler GmbH (Germany)

- Method: Solvolysis using proprietary solvents at 150–200 °C.

- Output: Recovered neoprene oligomers (>90% purity).

- Specialty: Handles mixed‐rubber blends.

- Teijin Ltd. (Japan)

- Method: Hydrothermal devulcanization.

- Output: Reclaimed chloroprene monomers for new sheets.

- Lead Time: 4–6 weeks from receipt.

| Facility | Technology | Min. Batch | Output Quality |

|---|---|---|---|

| Lehigh Technologies | Cryogenic + Devulc. | 1,000 kg | Micronized Crumb |

| Kreussler GmbH | Solvolysis | 500 kg | Oligomer Purity >90% |

| Teijin Ltd. | Hydrothermal Devulc. | 2,000 kg | Recovered Monomer |

For B2B clients ordering custom neoprene bags or koozies, consolidating scrap across multiple SKUs and partnering with a freight forwarder can unlock access to these recycling partners—turning end‐of‐life inventory into a measurable sustainability win.

What Are the Main Challenges and Limitations in Neoprene Recycling?

Recycling neoprene faces hurdles including: mixed‐material delamination, additive variability, contamination from hardware (zippers, grommets), and high minimum‐batch requirements. Economic barriers—energy costs, specialized reactors, feedstock sorting—limit profitability for small OEM runs. Regulatory compliance for emissions and solvents further increases CAPEX. Yet strategic design‐for‐recycling, centralized take-back programs, and shared infrastructure can mitigate these challenges over time.

- Material Complexity

- Laminates & Coatings: Adhesive removal is labor‐intensive; some coatings resist thermal breakdown.

- Additive Diversity: Plasticizer types dictate devulcanization pathways; mismatches lower yield.

- Contamination & Sorting

- Hardware Removal: Metal eyelets and Velcro must be manually stripped to avoid equipment damage.

- Quality Control: Impure batches can poison catalysts or clog extruders, halting operations.

- Batch Economics

- Scale Requirements: Facilities often mandate ≥500 kg (≈1,100 lb) per shipment, delaying recycling for small orders.

- Energy & Solvent Costs: Chemical recycling may consume 3–5 MJ/kg of neoprene; solvent recovery systems add overhead.

- Regulatory & Safety

- Emissions Controls: Solvolysis and pyrolysis units require scrubbers to capture VOCs and acid gases.

- Worker Safety: Handling hot, pressurized reactors and chemical catalysts demands rigorous protocols.

While these obstacles are real, they’re not insurmountable. Aggregating scrap across multiple product lines, specifying simpler formulations, and engaging co-manufacturers can lower thresholds—empowering brands to pilot circular neoprene with minimal risk.

How Can Manufacturers and Brands Integrate Recycling into Their Supply Chain?

Brands can launch closed-loop programs by designing for disassembly, offering take-back incentives, and selecting partners with scalable recycling tech. Free sample runs and low-MOQ custom batches create pilot volumes for recyclers. Transparent labeling and batch tracking streamline feedstock qualification. By embedding recycled content specifications into RFQs and leveraging OEM/ODM flexibility, companies can transform end-of-life neoprene from liability to value driver—and boost procurement’s ESG credentials in the process.

- Design for Disassembly

- Modular Components: Use snap-in hardware instead of glued seams to simplify teardown.

- Simplified Formulations: Limit coating layers and choose compatible adhesives.

- Take-Back & Incentive Programs

- Client Returns: Offer discounts or free freight on scrap returned from large clients.

- Reward Structures: Credits toward future orders when customers return old neoprene items.

- Pilot Runs & Low-MOQ Tests

- Free Sample Campaigns: Collect 50–100 units of scrap from sample programs to prove process viability.

- Private-Label Consolidation: Pool scrap from multiple small clients for volume thresholds.

- Supply-Chain Transparency

- Batch Tracking: Use QR codes or RFID tags to trace scrap back to formulations.

- Certifications: Work with GRS or ISO bodies to validate recycled content claims.

By weaving these elements into manufacturing and procurement, B2B buyers can steadily scale circular neoprene—reducing waste, cutting costs, and differentiating their brands in a crowded market.

Do Recycled Neoprene Products Maintain Performance and Quality?

Recycled neoprene can match 80–95% of virgin material’s tensile strength, compression set, and UV stability when processed via chemical routes. Mechanical recyclates excel in lower‐stress applications like padded cases or insulation sleeves. Case studies show custom neoprene bags with 20% recycled content passing standard EN 1210 abrasion tests and ISO 812 compression cycles—proving that sustainability need not compromise performance.

- Mechanical vs. Chemical Grades

- Mechanical Recyclates: Ideal for gaskets, padding, and non-load bearing covers; tensile strength ~80% of virgin.

- Chemical Reclaim: Near-virgin polymers suitable for high-stretch applications; tensile retention >90%.

- Key Performance Metrics

- Tensile Strength: Recycled chemically: ~23 MPa vs. 25 MPa virgin.

- Compression Set: Maintains <15% set after 22 h at 70 °C (ISO 815).

- UV Resistance: Carbon black levels preserved during devulcanization.

- Real-World Case Study

- Client: Outdoor gear brand integrated 30% chemically recycled neoprene in their signature paddle-board bag.

- Outcome: Passed MIL-STD abrasion tests; customer satisfaction climbed 12% due to eco-credibility.

- Design Adjustments

- Blend Ratios: Balancing recycled content (10–40%) with virgin polymer to hit tier-1 specs.

- Additive Tuning: Reintroducing antioxidants post-recycle to restore longevity.

These results affirm that recycled neoprene can uphold rigorous B2B standards—making it an attractive choice for conscious brands seeking performance without compromise.

Are There Industry Standards and Certifications for Recycled Neoprene?

Global Recycled Standard (GRS), Recycled Content Certification (RCC), and ISO 14021 provide frameworks for verifying recycled neoprene claims. They stipulate minimum post-consumer or post-industrial content (e.g., 20–50%) and chain-of-custody controls. B2B buyers can require GRS labeling in RFQs to ensure traceability. These certifications build trust and align with corporate sustainability goals, simplifying reporting for ESG audits and green procurement policies.

- Global Recycled Standard (GRS)

- Scope: 3rd‐party verification of recycled content, chemical usage, and social compliance.

- Thresholds: Products ≥20% recycled material qualify; above 50% earns “high recycled” label.

- Recycled Content Certification (Textile Exchange RCC)

- Focus: Quantitative mass‐balance accounting of recycled polymer feedstock.

- Benefits: Recognized by major brands for sustainable sourcing.

- ISO 14021 (SelfDeclared Environmental Claims)

- Guidance: Defines “recycled content” and prohibits vague claims.

- Application: Useful for internal quality controls and purchaser transparency.

- Implementing Certifications

- Documentation: Material Safety Data Sheets (MSDS) and mill certificates to track recycled percentages.

- Audits: Periodic facility inspections to confirm chain-of-custody integrity.

By embedding these standards into product specs, B2B buyers can confidently source recycled neoprene that meets both technical and ethical benchmarks—strengthening brand reputations and satisfying investor scrutiny.

What Future Innovations Will Enhance Neoprene’s Circularity?

Next-gen breakthroughs—enzymatic devulcanization, bio-based chloroprene, and solventless lamination—promise to slash energy use by 50% and eliminate VOC emissions. Pilot-scale “smart reactors” adapt process parameters in real time to optimize yield. Meanwhile, startups are exploring algae-derived polymers that mimic neoprene’s properties. These innovations could democratize recycling for small OEM runs, paving the way for truly circular neoprene across every application.

- Enzymatic & Bio-Catalytic Devulcanization

- Concept: Tailored enzymes selectively cleave sulfur crosslinks at ambient temperatures.

- Advantages: Lower energy, minimal emissions; still in R&D.

- Bio-Based Monomers

- Source: Plant-derived chloroprene precursors reduce petrochemical dependence by up to 60%.

- Impact: When combined with chemical recycling, enables cradle-to-cradle supply chains.

- Solventless & Waterborne Adhesives

- Innovation: UV-cured acrylics and waterborne PU laminates simplify disassembly and cut VOCs by >90%.

- Benefit: Streamlines mechanical recycling by eliminating solvent residues.

- Modular Recycling Pods

- Design: Container-sized units that sit near factories for on-site scrap processing.

- Scalability: Lowers shipping costs and batch thresholds, making recycling workable for even small custom runs.

As these technologies mature, the barriers to neoprene circularity will continue to fall—unlocking new opportunities for Szoneier and its clients to lead in sustainable custom manufacturing.

Whether you’re sourcing custom neoprene sleeves, koozies, or high-performance wetsuits, integrating recycled content is no longer a niche option—it’s a competitive edge. Ready to explore sustainable neoprene solutions tailored to your brand?

Let’s build the circular neoprene products your customers will love—without ever touching a landfill.