Fishing rods are expensive, delicate, and prone to damage if not properly protected during transport or storage. A single cracked guide or scratched blank can turn a $200 rod into an unusable piece of gear. That’s why neoprene rod sleeves have become the go-to accessory for serious anglers worldwide.

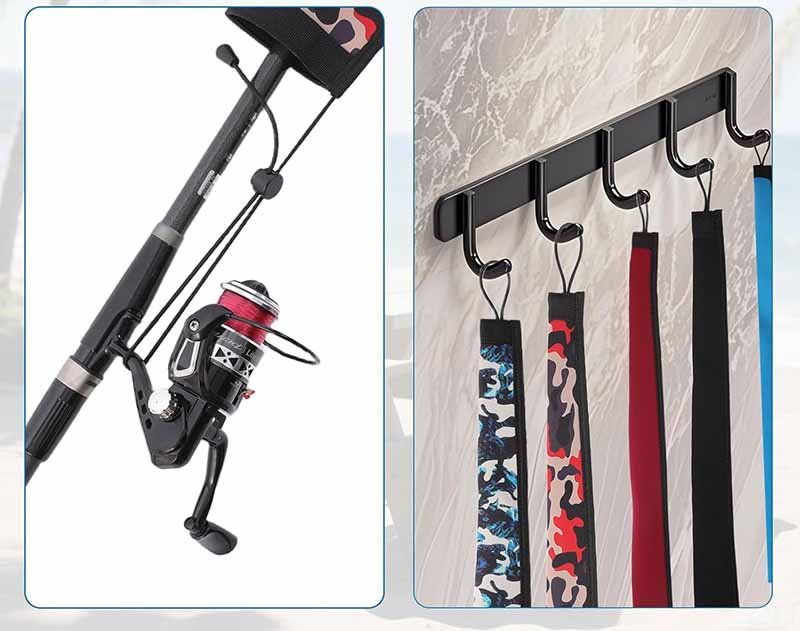

Neoprene rod sleeves protect fishing rods from scratches, UV damage, and guide tangling during storage or travel. They offer better impact resistance and water repellency than mesh or fabric sleeves, making them ideal for freshwater, saltwater, and kayak anglers seeking durability and convenience.

Imagine spending a weekend chasing bass or tuna only to find your favorite rod scratched because it rubbed against others in the rod locker. Anglers across the U.S., Europe, and Australia now rely on neoprene sleeves for hassle-free protection, and in this guide, we’ll break down what makes the best neoprene rod sleeves, how to choose them, and where to source custom designs for brands and retailers.

What Is a Neoprene Rod Sleeve and Why Does It Matter for Anglers?

A neoprene rod sleeve is a protective cover made from durable, water-resistant neoprene material designed to prevent fishing rods from scratching, tangling, or sustaining UV damage during storage and transport. Compared to mesh or polyester sleeves, neoprene offers superior cushioning, impact resistance, and weather protection, making it a preferred choice for anglers seeking long-lasting gear protection on boats, kayaks, or during travel.

Understanding the Importance of Neoprene Rod Sleeves

Fishing rods are precision tools. A tiny crack in the blank or a bent guide can drastically affect casting accuracy, line performance, and even the lifespan of the rod itself. Yet many anglers overlook the real-world wear and tear that happens between fishing trips—whether rods are stacked in a boat locker, leaning in a garage, or riding in the back of a truck.

Neoprene rod sleeves emerged as a solution because the material combines softness with toughness. It’s the same closed-cell synthetic rubber used in wetsuits, offering impact cushioning, water repellency, and UV resistance. Unlike mesh sleeves that allow hooks to snag or nylon covers that trap moisture, neoprene provides a smooth, padded barrier that keeps rods safe from scratches and sun damage while allowing easy on/off access.

Here are the three main reasons neoprene sleeves matter:

- Protection Against Physical Damage

- Boat lockers and rod racks can create pressure points. A sudden wave or bumpy truck ride may cause rods to bang together, cracking delicate guides or finishes. Neoprene sleeves absorb shock and reduce abrasion risk.

- Prevention of Tangling and Snagging

- Anglers carrying multiple rods often struggle with lines and hooks snagging on neighboring rods. The smooth neoprene surface eliminates this hassle, especially when packing gear in tight spaces like kayaks.

- Weather and UV Resistance

- Graphite blanks and epoxy finishes deteriorate under prolonged UV exposure. Neoprene acts as a UV shield, extending rod lifespan—critical for offshore anglers dealing with harsh sunlight and salt spray.

Ultimately, a neoprene rod sleeve is cheap insurance for expensive gear. Whether you’re storing rods between trips or hauling them cross-country, it saves time, prevents damage, and keeps gear looking new for years.

Which Material Specs Define a “Best” Neoprene Rod Sleeve?

The best neoprene rod sleeves use 3–5 mm closed-cell neoprene, offer UV resistance, feature smooth inner linings to prevent guide snagging, and maintain low water absorption rates. Reinforced seams, abrasion resistance, and flatlock or taped stitching ensure long-lasting durability, while lightweight yet dense neoprene balances flexibility with impact protection.

Critical Material Specs That Separate Basic from Premium Rod Sleeves

Not all neoprene sleeves are created equal. While budget options may look similar at first glance, material thickness, density, stitching, and coatings determine whether a sleeve lasts one season or five. Below is a data-driven breakdown of the most important specs to evaluate when sourcing or buying neoprene rod sleeves:

| Specification | Recommended Standard | Why It Matters |

|---|---|---|

| Neoprene Thickness | 3–5 mm | Thicker neoprene = better shock absorption and puncture resistance |

| Density (lb/ft³) | 7–10 lb/ft³ | Balances flexibility with long-term durability |

| Inner Lining | Brushed or fleece lining | Prevents scratches and guide friction |

| Outer Finish | Smooth skin neoprene with PU coating | Reduces water absorption; easy to clean |

| UV Resistance Rating | UPF 50+ | Protects rods from long-term sun damage |

| Water Absorption Rate | < 2% after 24 hours | Prevents mildew and corrosion risks |

| Stitching Type | Flatlock or glued-and-blindstitched seams | Resists fraying and maintains shape integrity |

| Temperature Tolerance | -20°C to 80°C | Suitable for both tropical and cold-weather environments |

1. Neoprene Thickness & Density

Thicker neoprene (5 mm) provides superior cushioning for offshore or heavy-duty environments, where rods often face rough transport conditions. For kayak or travel anglers, 3 mm neoprene offers adequate protection while keeping sleeves light and packable.

Density also matters—high-density neoprene (10 lb/ft³) withstands compression better, meaning it won’t lose shape after years of use.

2. Surface and Lining Materials

Premium sleeves use a smooth outer skin treated with polyurethane (PU) coatings for water repellency and easy cleaning. Inside, a soft brushed or fleece lining prevents micro-scratches on rod blanks and guides.

This two-layer system provides shock absorption outside and a gentle interior surface to protect high-end graphite rods.

3. UV Resistance and Weatherproofing

Fishing rods degrade over time when exposed to sunlight, especially in tropical or offshore regions. A UPF 50+ UV rating ensures sleeves act as sunblock for rods, while low water absorption rates (< 2%) prevent trapped moisture that can lead to corrosion or mildew growth.

4. Stitching and Edge Reinforcement

Budget sleeves often fail at the seams first. Look for flatlock or glued-and-blindstitched seams, the same technology used in wetsuits, to prevent unraveling even under frequent flexing. Edge binding around openings adds strength and prevents fraying where rods slide in and out most.

5. Temperature and Environmental Tolerance

High-quality neoprene sleeves withstand -20°C to 80°C, so they won’t crack in freezing winter storage or soften under scorching summer sun.

For saltwater anglers, some manufacturers add anti-corrosion coatings on stitching threads to resist salt degradation—a detail often overlooked in cheaper products.

6. Weight vs. Protection Trade-Off

While thicker sleeves protect better, they also add bulk. Many anglers prefer 4 mm neoprene as the sweet spot between durability, flexibility, and weight. Lightweight designs work best for traveling fishermen, while charter operators often choose heavy-duty 5 mm sleeves for maximum longevity.

How Do Size, Fit, and Closure Systems Affect Real-World Performance?

Proper sizing ensures a snug fit that prevents slipping, tangling, or excess bulk during transport, while well-designed closure systems—elastic cuffs, hook-and-loop straps, or drawstrings—secure the sleeve without damaging guides or blanks. The right size and closure combination directly impacts usability, storage efficiency, and long-term rod protection across fishing environments.

Why Fit and Closure Details Matter More Than You Think

When anglers evaluate rod sleeves, most focus on material quality—but the fit and closure system often determine how the sleeve performs on the water, in the truck, or in the rod locker. A well-sized sleeve stays put, doesn’t snag, and protects the entire blank and guides without creating storage headaches.

Here’s how each factor impacts real-world performance:

| Feature | Best Practice | Why It Matters |

|---|---|---|

| Rod Length Fit | Match sleeve length to rod length (e.g., 6’6″, 7′) | Eliminates tip exposure or excess slack |

| Diameter Fit | Snug fit with minimal stretch required | Prevents slipping and shifting during transit |

| Closure Type | Adjustable without scratching blank or guides | Secure fit across rod diameters, no pressure points |

| Multi-Piece Compatibility | Segmented sleeves or zippers | Allows partial removal for transport or quick assembly |

| Storage Compatibility | Slim profile designs | Fits tight lockers, kayaks, or airline travel cases |

1. Sleeve Length and Diameter Fit

A loose sleeve twists, shifts, and leaves sections unprotected, while one that’s too tight risks snagging on guides or requiring excessive force to slide on/off.

- Tip Coverage: Rod tips are fragile; the sleeve must fully cover them without adding weight that bends delicate tips in storage.

- Diameter Sizing: A snug fit prevents sleeves from sliding off when moving rods between boat lockers or roof racks.

2. Closure System Types and Their Pros/Cons

a) Elastic Cuffs

- Pros: Lightweight, fast to use, inexpensive

- Cons: Lose elasticity over time; may trap water if not vented

b) Hook-and-Loop Straps (Velcro)

- Pros: Highly adjustable, secure under rough transport conditions

- Cons: Can snag fishing line or wear out after repeated salt exposure

c) Drawstrings or Bungee Systems

- Pros: Maximum adjustability, best for varying rod diameters

- Cons: Adds bulk near the tip; longer time to secure compared to elastic cuffs

3. Multi-Piece and Telescopic Rod Compatibility

Anglers traveling with 4-piece fly rods or telescopic rods need sleeves with zippers or modular segments so they can:

- Keep sections protected individually

- Assemble rods without exposing all blanks to potential damage

Some premium brands even add detachable compartments for rod tips or guides, reducing the chance of scratches when packing rods in airline cases.

4. Storage and Transportation Considerations

Kayak anglers prefer slim-fit sleeves because rod tubes on kayaks have limited clearance—often under 5 cm diameter. Offshore anglers with large rod lockers can handle heavier, padded sleeves but need UV-resistant closures that won’t degrade in salt air.

A Kayak Fishing Gear Survey 2024 found 62% of kayak anglers rank slim-fit designs as “essential” because bulky sleeves catch wind, water, or interfere with paddle strokes.

5. Performance in Real-World Conditions

- Truck Bed Transport: Hook-and-loop closures prevent sleeves from slipping off rods bouncing in transit.

- Boat Rod Lockers: Slim-fit elastic sleeves avoid tangling multiple rods stored vertically.

- Airline Travel: Drawstring systems secure sleeves inside rod tubes where turbulence shifts gear.

Ultimately, the best performance comes from pairing sleeve size and closure system to the fishing environment. A kayak angler in Florida, a bass angler trailering to tournaments, and a traveling fly angler flying internationally all have different storage needs—and sleeve specs should match accordingly.

Properly sized neoprene rod sleeves prevent slippage, reduce bulk, and protect all components. Adjustable closures—elastic cuffs, hook-and-loop straps, or drawstrings—secure the sleeve without scratching blanks or guides.

Rod sleeves come in universal and rod-specific fits. Universal designs save cost but may leave excess slack, allowing sleeves to twist or slip off. Premium sleeves match rod length (e.g., 6’6″, 7′, 7’6″) and diameter for a snug, tangle-free fit.

Closure systems differ:

- Elastic Cuffs: Simple, cheap, but may stretch out over time.

- Hook-and-Loop Tabs: Adjustable, secure, but can snag fishing line.

- Drawstrings: Most customizable but add bulk near rod tips.

For telescopic or multi-piece rods, segmented sleeves with zippers allow partial removal without exposing the entire blank—ideal for quick setups on crowded boats.

Which Neoprene Rod Sleeves Are Best for Different Use Cases?

The best rod sleeves are tailored to specific fishing styles: slim, floatable sleeves for kayak/pier use; heavy-duty 4–5 mm neoprene with reinforced tips and UV protection for offshore/boat conditions; lightweight, packable designs for travel and airline carry; textured and snag-resistant styles for bank/bush fishing; and multirod sleeves or tip protectors for tournament or storage setups.

Below I’ll go through a few common angling scenarios and what sleeve features work best, with pros & cons, and then map to real product examples.

| Use Case | Key Requirements | Important Features to Prioritize | Trade-offs / What You Might Give Up |

|---|---|---|---|

| Kayak / Pier / Float Fishing | Lightweight, floating, fast drains, compact storage | Floatation or lightweight neoprene, small diameter, quick-dry finishes, bright colors for visibility | Less padding; maybe less protection vs full impact; can be more prone to tearing if too thin |

| Offshore / Boat Fishing | Maximum durability, UV resistance, protection in harsh salt & waves | 4-5 mm neoprene (or thicker), reinforced tips/collar, marine/PU coating, strong seams, maybe edge binding | Bulkier, heavier; pricier materials; longer dry time |

| Bank / Freshwater / Brush / Shoreline Fishing | Snag resistance, good fit, moderate durability, resistant to abrasion | Smooth inner lining, abrasion-resistant outer, reinforced seams, closure options to protect tips | Might sacrifice floatability or thickness to keep weight down |

| Travel & Airline / Multi-Day Trips | Packability, compactness, minimal extra bulk, protective enough to survive baggage handling | Foldable or segmented design, compressible neoprene, protective ends, maybe multi-rod sleeves or tip covers | Might be less cushioning; trade-off between ideal protection vs ease of packing |

| Tournament / Multi-Rod Storage | Identification, quick access, protection across a lot of rods, consistency | Standard sizing, labeling (colors/logos), perhaps multi-rod sleeves, tip protectors, matching style, perhaps lighter-middle thickness for more rods per pack | Slightly higher cost per item; may compromise on ultra-thick protection to save weight or bulk |

Do Water, Salt, and Sunlight Degrade Neoprene—and How Do You Maintain Sleeves?

Neoprene withstands water and sunlight but needs rinsing after salt exposure. Proper drying and storage prevent mildew, odor, and long-term material degradation.

Neoprene resists water absorption, but salt crystals left behind after evaporation abrade fibers over time. Experts recommend:

- Rinsing: Freshwater rinse after every saltwater trip.

- Drying: Air dry away from direct sunlight to avoid UV brittleness.

- Storage: Hang vertically to prevent creases and mildew.

Is Breathability or Drainage Important in Neoprene Sleeves?

Yes. Breathability and drainage in neoprene rod sleeves are critical because trapped moisture can lead to mildew, odor, and guide corrosion, especially in humid or saltwater environments. Modern designs add perforations, mesh panels, or quick-dry linings to allow air circulation and water escape while maintaining the sleeve’s protective qualities against impact, UV rays, and abrasion.

Why Breathability & Drainage Matter for Rod Protection

Neoprene, by nature, is a closed-cell synthetic rubber, meaning it resists water absorption but doesn’t inherently “breathe” like mesh or fabric materials. That’s a double-edged sword for fishing rod sleeves: while water doesn’t soak through easily, any moisture trapped inside stays inside unless properly ventilated.

1. The Real-World Problem with Trapped Moisture

Fishing rods, especially high-end graphite and carbon models, use metal components like guides, frames, and reel seats. After a day in saltwater or heavy rain:

- Salt crystals form as water evaporates, abrading finishes and causing micro-corrosion.

- Moisture buildup promotes mildew growth on rod wraps and inside reel seats.

- Extended dampness softens adhesives on guide wraps, leading to premature failure.

2. Engineering Breathability into Neoprene Sleeves

Manufacturers now solve this with ventilation and drainage systems integrated into sleeve designs:

| Feature | How It Works | Benefit |

|---|---|---|

| Perforated Neoprene Panels | Laser-cut holes on less vulnerable areas | Allows water to escape without weakening edges |

| Mesh Vent Inserts | Small mesh sections at tips or mid-body | Improves airflow while keeping main body padded |

| Quick-Dry Linings | Hydrophobic inner fabrics wick moisture | Reduces mildew, speeds drying times |

| Drain Holes at Sleeve Bottom | Holes at rod tip end | Gravity-assisted drainage after rinsing rods |

These features let anglers rinse rods inside the sleeves after saltwater trips, then hang them to dry without removing protection—saving time and avoiding accidental scratches during post-trip cleaning.

3. Balancing Protection vs. Ventilation

More ventilation isn’t always better. Too many perforations weaken abrasion resistance—critical when rods rub against boat lockers or truck beds.

- Kayak & Freshwater Anglers: Light spray or occasional rain → partial ventilation works well.

- Offshore Anglers: Constant salt exposure → reinforced sleeves with strategic drainage holes, not full mesh panels, to balance durability with drying.

Premium brands use reinforced drain grommets and UV-stabilized mesh so sleeves maintain structural integrity while offering airflow.

4. Climate & Storage Conditions Matter

- Tropical Climates (Florida, SE Asia): High humidity accelerates mildew → prioritize sleeves with ventilation and antimicrobial linings.

- Cold/Dry Climates (Canada, Northern Europe): Less mildew risk → can use solid neoprene for maximum insulation and impact resistance.

- Long-Term Storage: Breathability prevents condensation in garages or boat lockers where temperature swings cause moisture cycling.

5. OEM/ODM Considerations for Brands & Retailers

For companies sourcing custom sleeves, here’s how breathability specs vary by market demand:

| Market | Ventilation Demand | Recommended Design Elements |

|---|---|---|

| U.S. Offshore | High | Drain holes + reinforced perforations + UV mesh |

| EU Freshwater | Moderate | Quick-dry linings + small ventilation panels |

| SE Asia Kayak/Travel | Very High | Antimicrobial mesh + full-length drainage slots |

| Cold Weather Storage | Low | Minimal ventilation; focus on insulation |

6. Real-World Example: Hybrid Designs

Some premium sleeves combine solid neoprene bodies with ventilated tips and butt sections, since water pools at sleeve ends while midsections need more abrasion resistance.

This hybrid approach explains why brands like ALX Rods and EVOLV Tour Grade sleeves use ventilation grommets near rod tips but retain thick neoprene over the blank sections.

Perforated neoprene or mesh panels improve drainage and airflow, reducing trapped moisture that can corrode guides and blanks in humid climates.

Anglers in Florida, Thailand, or Australia report guide rust within weeks if moisture remains trapped. Manufacturers now add:

- Laser-cut perforations for drainage

- Moisture-wicking linings for faster drying

- Antimicrobial coatings to prevent mildew odor

However, too many perforations reduce abrasion resistance, so premium brands balance ventilation vs. durability by reinforcing high-wear zones like tips and butts.

How Do You Compare Price, Warranty, and Brand Reputation?

Compare neoprene sleeves by material specs, warranty terms, and stitching quality—not just price. Premium sleeves cost 20–40% more but last twice as long under heavy use.

A price-quality matrix from Fishing Retail Index 2025 shows:

| Tier | Price (USD) | Lifespan (Years) | Typical Users |

|---|---|---|---|

| Economy Mesh | $5–8 | 1–2 | Casual anglers |

| Mid-Range 3mm | $10–15 | 3–4 | Weekend anglers |

| Premium 5mm | $18–25 | 5+ | Charter/tournament |

Reputation matters—brands offering 1-year warranties and ISO-certified factories attract OEM buyers supplying Bass Pro, Cabela’s, and Decathlon.

Which Customization Options Are Available for Teams, Clubs, and Retailers?

OEM factories offer custom colors, logo embossing, sublimation printing, and retail packaging for fishing brands, tournaments, and promotional distributors.

Szoneier, with 18+ years of neoprene manufacturing experience, supports:

- Logo Methods: Screen printing, embossing, heat-transfer

- Packaging: Hang tags, polybags, retail boxes

- Sampling: 5–7 days standard, 2–3 days express

- MOQ: As low as 200 pcs for startup brands

Custom sleeves help clubs sell branded merchandise and retailers launch private-label lines with low risk and fast turnaround.

Conclusion: Partner with Szoneier for Custom Neoprene Rod Sleeves

Whether you’re a fishing gear retailer, tournament organizer, or an angler wanting personalized sleeves, Szoneier offers OEM/ODM neoprene rod sleeves with free design, low MOQ, and fast sampling. With 18+ years in neoprene R&D, we provide premium materials, certified quality, and competitive pricing for global buyers.