Neoprene is everywhere—wrapped around coffee cups as koozies, cushioning laptops in sleeves, insulating divers in cold water, reinforcing medical braces, and protecting tools on factory floors. Yet most buyers still ask a deceptively simple question before they launch a product line: what exactly is neoprene fabric made of, and how does that chemistry translate into real-world performance? If you’re scoping a new bag program, refreshing your wetsuit range, or exploring protective covers for electronics, understanding ingredients, process, and properties will save you rounds of sampling, reduce returns, and sharpen your spec sheets.

Neoprene fabric is made from polychloroprene (a synthetic rubber formed by polymerizing chloroprene) plus functional additives such as carbon black for UV protection, zinc oxide for durability, and sulfur for vulcanization. The rubber is foamed into a closed-cell structure, then laminated with textiles (commonly nylon or spandex) to create durable, printable sheets in various thicknesses (typically 1–5 mm) for bags, koozies, gloves, braces, and wetsuits.

At Szoneier, we’ve spent 18+ years turning that science into consistent, scalable products—blending CR/SBR where it makes sense, tuning density for shock absorption, and pairing the foam with the right face fabrics for color, handfeel, and print clarity. Below, we decode the chemistry, walk the line through the factory, compare neoprene to look-alike materials, and show you the fastest path to a production-ready spec—complete with low MOQs, free design, free samples, and a 14-day prototyping cycle.

What Exactly is Neoprene Fabric?

Neoprene is a synthetic rubber (polychloroprene) engineered as a closed-cell foam, then laminated with fabrics like nylon or spandex to create sheets with insulation, water resistance, and impact damping. It balances stretch, structure, and printability—ideal for protective soft goods (bags, sleeves, covers), performance wear (wetsuits), and support products (braces). Szoneier builds consumer and industrial neoprene with consistent density, recovery, and surface finish for OEM/ODM orders.

Neoprene starts life as polychloroprene—rubber synthesized in reactors—then becomes a foam via gas expansion during curing. The result is closed cells (tiny air pockets) that trap air for thermal insulation and restrict water ingress. Contrast this with open-cell foams (like upholstery foams), which breathe more but insulate and repel water less effectively.

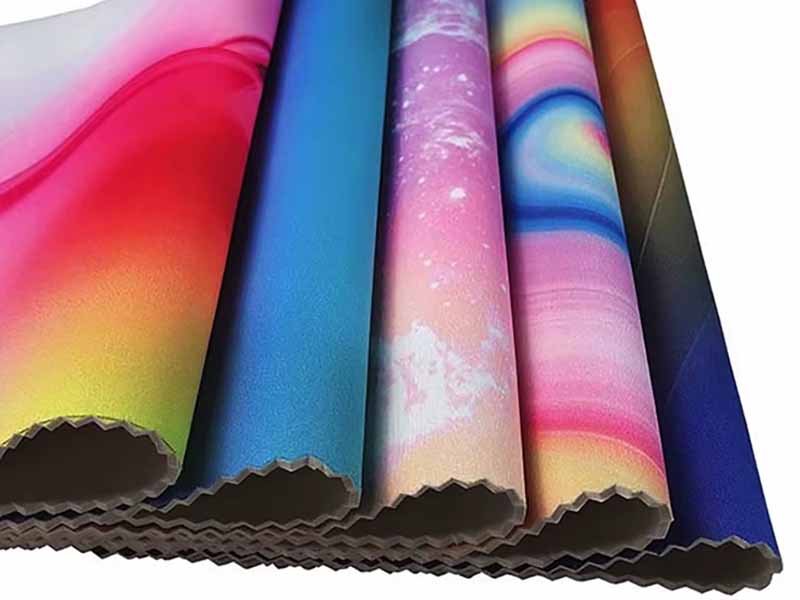

Once foamed, we convert the rubber sheet into a laminated fabric by bonding textiles to one or both faces. Typical pairings are Nylon (polyamide) knits for strength and abrasion resistance, and Spandex/Lycra knits for stretch and comfort. Surface choices—brushed, matte, glossy, embossed—control handfeel, glare, and brand look. This lamination step is also where your branding comes alive: white nylon is perfect for sublimation printing; darker or textured surfaces love screen or heat-transfer graphics.

For buyers, neoprene’s appeal is practical:

- Forgiving fit: foam + knit lamination stretches around contents.

- Protection: cells cushion drops; rubber resists abrasion and oils.

- Clean silhouette: edge-bound seams and molded panels elevate perceived value.

- Production flexibility: kiss-cut parts, bonded seams, or stitched assemblies scale from pilot to mass production.

Szoneier’s job is to translate your use case into the right thickness, density, lamination, and finish—and then run it with tight QC so every carton matches your photo sample.

What is Neoprene Fabric Made Of?

Neoprene is primarily polychloroprene rubber made by polymerizing chloroprene. Common additives include carbon black (UV/strength), zinc oxide (durability), antioxidants (aging), and sulfur (vulcanization). Feedstocks can be petroleum-based or limestone-based; both yield polychloroprene, but with different upstream footprints. Szoneier offers CR, SBR, and SCR blends to balance performance and cost.

The base polymer is polychloroprene (CR). On its own, CR has good inherent flame, oil, and ozone resistance, which is why neoprene outlasts many general-purpose foams outdoors. To tune the foam for real life, compounders mix in purposeful ingredients:

| Ingredient | Typical Role in Neoprene | Benefit in Finished Fabric |

|---|---|---|

| Carbon Black | Reinforcing filler, UV stabilizer | Strength, tear resistance, UV stability, darker base |

| Zinc Oxide | Activator / durability enhancer | Improved heat aging, vulcanization efficiency |

| Sulfur / Accelerators | Crosslinking (vulcanization) | Elastic network, recovery, compression set control |

| Antioxidants/Antiozonants | Aging protection | Slows cracking, preserves elongation & color |

| Blowing Agents | Gas generation during curing | Creates closed-cell foam (insulation, buoyancy) |

| Plasticizers | Flex modification | Softer handfeel, better low-temp flexibility |

| Fire Retardants (as needed) | Flame behavior tuning | Meets product or regional safety specs |

CR vs. SBR vs. SCR

- CR (Polychloroprene): Best overall balance; superior weathering, moderate oil resistance, good mechanicals.

- SBR (Styrene-Butadiene Rubber): Cost-effective, decent wear, less chemical/UV resistance.

- SCR (CR/SBR blend): Smart middle ground—CR performance at closer-to-SBR cost for value-driven SKUs.

Limestone-based neoprene uses calcium carbonate (limestone) to produce acetylene, a precursor to chloroprene, instead of petroleum routes. The polymer is the same class, so performance is comparable; the difference is upstream energy source and marketing claims. Many brands prefer limestone paired with water-based adhesives to reduce solvent VOCs.

Szoneier keeps a stable bill of materials and can provide spec sheets and third-party test reports (e.g., SGS) per lot, including REACH/RoHS compliance where required.

How is Neoprene Fabric Manufactured?

Production flows through six steps: (1) polymerize chloroprene into CR; (2) compound with additives; (3) vulcanize; (4) foam to create closed cells; (5) laminate textiles (nylon/spandex/mesh); (6) quality test thickness, density, adhesion, color, and odor. Szoneier adds rapid prototyping and controlled curing to lock in color and handfeel.

1) Polymerization

Chloroprene monomers are polymerized to CR. Polymer chain length and distribution affect viscosity, elasticity, and eventual foam expansion. Think of this as “setting the DNA” of the rubber.

2) Compounding

We blend CR with the functional additives above. Fine control of accelerators, blowing agents, and carbon black determines foam uniformity, surface smoothness, and compression set (how quickly the foam rebounds after being squeezed).

3) Vulcanization (Pre-Cure)

Heat and pressure induce crosslinks between polymer chains, giving the rubber its elastic memory. Pre-vulcanization ensures stable behavior during foaming and prevents defects like large voids or weak skins.

4) Foaming & Curing

The compound is expanded under controlled temperature/time to form a closed-cell matrix. Uniform cell size = consistent buoyancy and insulation. Curing completes the crosslink network. This stage governs thickness tolerance and density—key to production repeatability.

5) Lamination

We bond knit fabrics—often Nylon (PA) or Spandex (Elastane)—to one or both sides using water-based or solvent-based adhesives depending on spec. For sublimation prints, white nylon facing is ideal. For rugged bags, we may choose a denser nylon or textured emboss to hide scuffs. For braces, a brushed loop pairs with hook fasteners.

6) Quality Testing

Incoming fabrics are shade-controlled (Pantone/Lab), adhesives are batch-tracked, and finished sheets are tested for:

- Thickness (e.g., ±0.2 mm tolerance typical)

- Density (foam mass per volume)

- Peel Strength (lamination adhesion)

- Compression Set & Recovery

- Colorfastness & Odor (important for consumer goods)

- REACH/RoHS/OEKO-TEX-aligned benchmarks upon request

Szoneier’s sample-to-mass-production control means the panel you approve is the panel we deliver—at low MOQs with free samples and fast turnarounds.

How Does Neoprene Fabric Compare With Other Fabrics?

Neoprene outperforms many soft materials in insulation, water resistance, and impact damping, but it’s heavier and less breathable than thin knits. It beats natural rubber in weathering, trades blows with nitrile on chemicals, and out-cushions spandex which is for stretch, not protection. EVA/TPE can be lighter and cheaper but compress sooner. Choose based on use-case.

When shortlisting materials, avoid apples-to-oranges comparisons. Here’s a pragmatic lens based on common buyer goals.

A. Property-Level Comparison

| Property / Material | Neoprene (CR/SCR) | Natural Rubber | Nitrile (NBR) | Spandex/Elastane Knit | EVA/TPE Foams |

|---|---|---|---|---|---|

| Insulation | High (closed-cell) | Medium | Low-Medium | Low | Medium |

| Water Resistance | High (closed-cell) | Medium | Medium-High | Low | Medium |

| Oil/Chemical Resistance | Good | Fair | Very Good | Poor | Fair |

| UV/Ozone Resistance | Good | Poor-Fair | Good | Good (depends on blend) | Fair |

| Compression Recovery | Good-Very Good | Good | Good | N/A (fabric) | Fair-Good |

| Breathability | Low | Low | Low | High | Low |

| Weight (for same thickness) | Medium-High | Medium | Medium | Low | Low |

| Cost | Medium | Medium | Medium-High | Low-Medium | Low |

B. Application Fit

- Protective sleeves & bags: Neoprene wins for cushioning + snug fit + printability. EVA/TPE win on weight/cost when protection needs are modest.

- Wetsuits & thermal gear: Neoprene’s closed cells and stretch laminations outperform spandex, which is not an insulator.

- Chemical gaskets: NBR may be preferable for oil exposure; CR is sufficient for general outdoor/industrial.

- Athleisure: Spandex blends for breathability and stretch—not a neoprene domain.

Compliance Note: Szoneier offers OEKO-TEX-aligned and REACH/RoHS-compliant options; we can supply SGS test reports against your target markets.

Why Choose Neoprene for Performance?

Choose neoprene when you need insulation, water resistance, impact damping, and a stable print surface. Its closed-cell structure traps air (warmth/buoyancy), resists water uptake, and cushions drops. With nylon/spandex laminations, it combines protection and stretch—ideal for bags, koozies, braces, covers, and wetsuits.

Performance comes from physics, not hype:

- Thermal Regulation Closed cells reduce convective heat loss. Even at 2–3 mm, neoprene adds noticeable warmth around bottles or electronics. For wetsuits, panel mapping (varying thickness by body zone) balances mobility vs. warmth.

- Water Behavior Neoprene foam doesn’t drink water the way open-cell foams do. While surface fabrics can get wet, the foam core resists saturation—helping sleeves and covers dry faster and resist odor.

- Impact & Vibration Damping Foam compresses and rebounds, spreading load over time. For bags, this is the difference between a scuffed corner and a cracked device. We tune density and compression set so protection persists after thousands of cycles.

- UV/Chemical/Weather Durability CR’s backbone resists ozone cracking and UV better than many general-purpose foams. Add carbon black and anti-aging packages, and outdoor life improves significantly.

- Surface Ready for Branding White nylon faces allow edge-to-edge sublimation with crisp color. For lifestyle bags, matte textures read premium under retail lighting; for industrial covers, embossed grains hide scuffs.

Bottom Line: If your product brief reads “protect, insulate, print well, keep shape,” neoprene is likely your fastest route to a successful SKU.

Which OEM/ODM Customization Options are Available?

Szoneier offers 1–5 mm standard thickness (0.5–10 mm on request), CR/SCR foam choices, nylon/spandex/mesh laminations, matte/gloss/embossed finishes, and sublimation/screen/heat-transfer printing. We provide free design, free samples, low MOQs, and ~14-day prototyping with full spec sheets and QC reports.

We treat neoprene as a toolkit you can tailor:

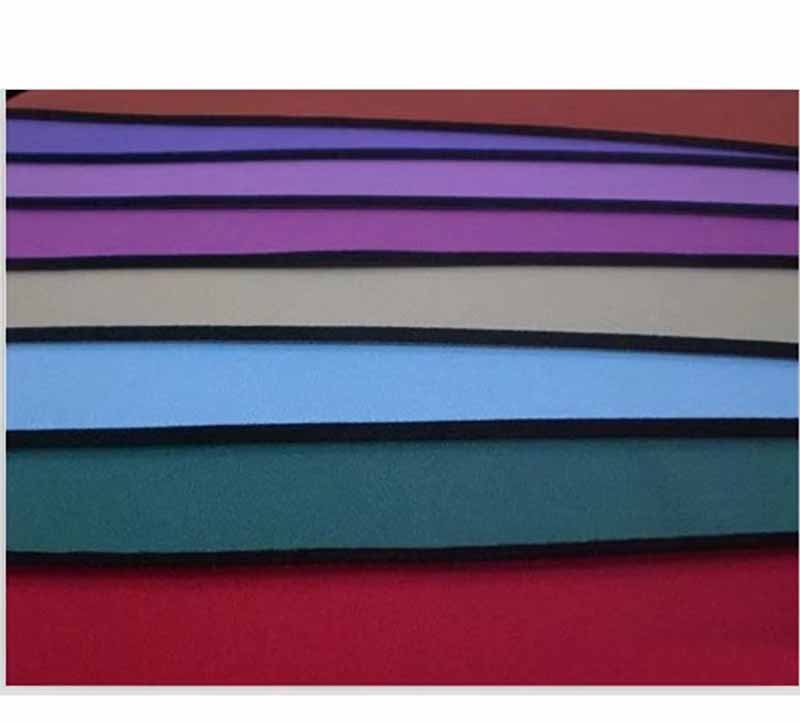

A. Foam & Thickness

- Standard: 1.0 / 2.0 / 3.0 / 4.0 / 5.0 mm

- Extended: 0.5–10 mm (lead time varies)

- CR vs. SCR: choose CR for premium longevity, SCR for value lines.

- Density/Hardness: tuned for cushioning vs. structure (e.g., stiffer for laptop sleeves, softer for braces).

B. Laminations & Faces

- Single-Face Nylon (one side knit, one side rubber “skin”)—weight savings, grippy interior.

- Double-Face Nylon—balanced strength and printability.

- Spandex/Lycra—comfort stretch for wearables.

- Mesh/Brushed Loop—hook-compatible braces and wraps.

- No-Lam/Skin-Skin—bonding/molding applications.

C. Surface Finishes

- Matte / Low-Sheen for premium bags

- Gloss for high-contrast prints

- Embossed/Grained for scuff-hiding, tactile branding

D. Printing & Branding

- Sublimation on white/PA faces for photo-quality graphics

- Screen print for solids/metallics

- Heat transfer for small logos or multi-material assemblies

- Pantone color matching for knit fabrics and edge binders

E. Converting & Assembly

- Die-cutting for accurate nesting and waste reduction

- Bonded seams (clean silhouette, water-resistant)

- Stitched construction (strength, classic look)

- Edge binding / zipper install / molded grips / Velcro® placements

F. Service & Speed

- Free design support: dielines, panel map, CMF suggestions

- Free samples: typical 14-day turnaround

- Low MOQs: start lean, scale quickly

- Documentation: spec sheets, COAs, and third-party tests upon request

Customization Snapshot

| Option | Choices | Notes |

|---|---|---|

| Foam | CR, SCR | SBR-heavy for cost, CR-heavy for durability |

| Thickness | 1–5 mm std; 0.5–10 mm req. | ±0.2 mm typical tolerance |

| Face Fabrics | Nylon, Spandex, Mesh, Loop | Sublimation loves white nylon |

| Finish | Matte, Gloss, Embossed | Brand-driven CMF |

| Sublimation, Screen, Heat-Transfer | Pantone-aligned | |

| Assembly | Bonded, Stitched, Hybrid | Edge binding for polish |

Where is Neoprene Fabric Used Across Industries?

Neoprene is a multi-industry workhorse: sports/outdoor (wetsuits, swim sleeves), consumer (bags, koozies, device sleeves), medical (braces), and industrial (gaskets, insulation, protective covers). Szoneier produces 10,000+ neoprene bags/month for global brands with stable QC and on-time delivery.

A. Sports & Outdoor

- Wetsuits & Tops: warmth, stretch, and panel shaping.

- Swim Sleeves & Gloves: targeted insulation with tactile grip.

- Knee/Elbow Supports: compression + heat retention to ease movement.

B. Consumer Goods

- Neoprene Bags & Pouches: shock absorption and shape retention.

- Koozies & Bottle Covers: temperature stability + brand billboard.

- Electronics Sleeves: snug fit protects from scuffs and light drops.

- Camera/Lens Covers: padded protection in variable weather.

C. Medical & Recovery

- Orthotic Braces, Wraps, Slings: brushed loop faces accept hook closures; foam cushions and warms joints.

D. Industrial & Commercial

- Gaskets & Pads: oil and ozone resistance with compression recovery.

- Protective Covers: tool, instrument, and machinery protection in transit.

- Sound/Thermal Insulation: damping panels in cases or enclosures.

E. Brand Collaboration Examples (typical builds)

- Lifestyle Tote: 3 mm SCR, double-face nylon, sublimation print, bound edges.

- Premium Laptop Sleeve: 4 mm CR, nylon + brushed lining, bonded seams for a lean profile.

- Value Koozie: 2 mm SCR, single-face nylon, screen-printed logo.

- Medical Knee Brace: 4–5 mm CR, loop outer + skin inner, hook straps.

Szoneier’s production lines are set up for mixed-SKU batches—you can test multiple thicknesses or finishes in one pilot run before you scale.

Is Neoprene Sustainable?

Neoprene’s closed-cell performance comes with sustainability trade-offs: recycling is limited, and some adhesive systems use solvents. Improvements include limestone-based feedstocks, water-based adhesives, efficient curing, and scrap upcycling. Alternatives like natural rubber (e.g., Yulex-type) or TPE exist, each with performance trade-offs. Szoneier helps balance durability, impact, and cost.

Sustainability has two levers: materials and longevity. Neoprene’s biggest wins come from long service life—fewer replacements mean fewer total resources—and from cleaner processes.

Material Pathways

- Limestone-based CR: Same polymer class, different upstream energy. Good narrative fit for brands; performance remains strong.

- Bio-based / Natural Rubber Alternatives: Great story and elastic performance, though chemical/UV resistance and long-term compression set can differ.

- TPE/EVA: Recyclability potential and weight savings; loses some durability and recovery vs. CR foams.

Process Improvements

- Water-Based Adhesives where possible (reduce VOCs).

- Energy-Efficient Curing (oven optimization and heat recovery).

- Dope-Dyed Linings (less water than post-dye processes).

- Scrap Upcycling (die-cut skeletons into small goods; regrind for non-critical pads).

Design for Durability

- Right thickness for duty cycle—under-spec’ing saves grams but sacrifices lifespan.

- Edge binding & corner reinforcement to stop early wear.

- Replaceable parts (straps, hook/loop) extend product life.

Sustainability Snapshot

| Strategy | What We Do | Buyer Benefit |

|---|---|---|

| Cleaner Feedstock | Limestone-based CR options | Lower upstream footprint narrative |

| Low-VOC Lamination | Water-based adhesives (where spec allows) | Safer factories, better air quality |

| Material Efficiency | Tight nesting; scrap upcycling | Less waste, lower cost per unit |

| Durability-First Specs | Thickness/density matched to use | Fewer returns, longer product life |

| Documentation | REACH/RoHS-aligned, third-party tests | Compliance clarity for global markets |

If you’re pursuing a sustainability claim, we’ll help select verifiable levers and provide the documentation your compliance team needs.

Helpful Reference Table: Thickness & Use-Case Matching

| Use Case | Typical Thickness | Foam Choice | Lamination | Notes |

|---|---|---|---|---|

| Koozies / Bottle Covers | 2–3 mm | SCR | Single-face nylon | Light, cost-effective, good print |

| Electronics Sleeves | 3–4 mm | CR/SCR | Double-face nylon or brushed inner | Balance protection & bulk |

| Lifestyle/Beach Bags | 3–4 mm | SCR | Double-face nylon, matte | Structure with soft hand |

| Camera/Lens Covers | 3–5 mm | CR | Nylon + embossed skin | Extra damping & scuff hiding |

| Knee/Elbow Braces | 4–5 mm | CR | Loop outer + skin inner | Hook-compatible, warm support |

| Wetsuits (panels) | 2–5 mm mix | CR | Nylon/Spandex | Zone thickness for mobility vs warmth |

| Industrial Pads/Covers | 3–6 mm | CR | Nylon or no-lam | Oil/ozone resistance prioritized |

Why Szoneier for Neoprene?

- 18+ years focused on neoprene soft goods and technical laminations

- 10,000+ neoprene bags/month capacity for stable brands

- Free design & samples, low MOQs, ~14-day prototyping

- CR/SCR options tuned to cost and performance targets

- Sublimation, screen, heat-transfer—retail-ready graphics

- Spec sheets & third-party test reports (e.g., SGS) available

- On-time delivery, carton-level QC, and repeatable shade control

Ready to Build Your Spec?

- Tell us your use case (bag vs sleeve vs wearable vs cover).

- Pick thickness & foam (start with 3 mm SCR for value, 4 mm CR for premium).

- Choose faces & finish (white nylon for sublimation; matte nylon for premium feel; loop for braces).

- Define branding (Pantone, print type, placement).

- Pilot run (free samples, 14-day typical).

- Scale with locked BOM and QC checkpoints.

When you’re ready to translate an idea into a spec that ships, Szoneier makes the path simple: free design support, free samples, low MOQs, and on-time mass production. Tell us your target price and performance, and we’ll propose the right CR/SCR build, lamination, and finish—complete with print tests.