Most neoprene owners eventually notice the same thing — what was once smooth, stretchy, and cushiony starts to feel stiff or rubbery. Whether it’s a wetsuit that’s lost its glide or a koozie that doesn’t hug the can like it used to, neoprene hardening is inevitable. But here’s the good news: in most cases, it’s not permanent. With the right techniques, you can safely restore that soft, flexible feel without damaging the material or its lamination.

To soften neoprene, soak it in lukewarm water with a mild fabric conditioner for 15–20 minutes, rinse gently, and air-dry flat in the shade. For deeper restoration, massage the surface or use a silicone-based neoprene spray to revive elasticity. Avoid heat or sunlight, which can cause the rubber to harden further. Consistent care keeps neoprene flexible and prolongs its lifespan.

Like skin that needs hydration after exposure to the elements, neoprene needs care after saltwater dives, sun exposure, or long storage. The way you soften and maintain it can determine how long your wetsuit, bag, or koozie lasts. In this guide, we’ll explore the science behind neoprene stiffness, the safest home methods to restore flexibility, and the professional techniques manufacturers like Szoneier use to keep their neoprene soft from day one. By the end, you’ll not only know how to soften neoprene — you’ll understand why it stiffens, and how to keep it supple for years to come.

What Is Neoprene and Why Does It Become Stiff Over Time?

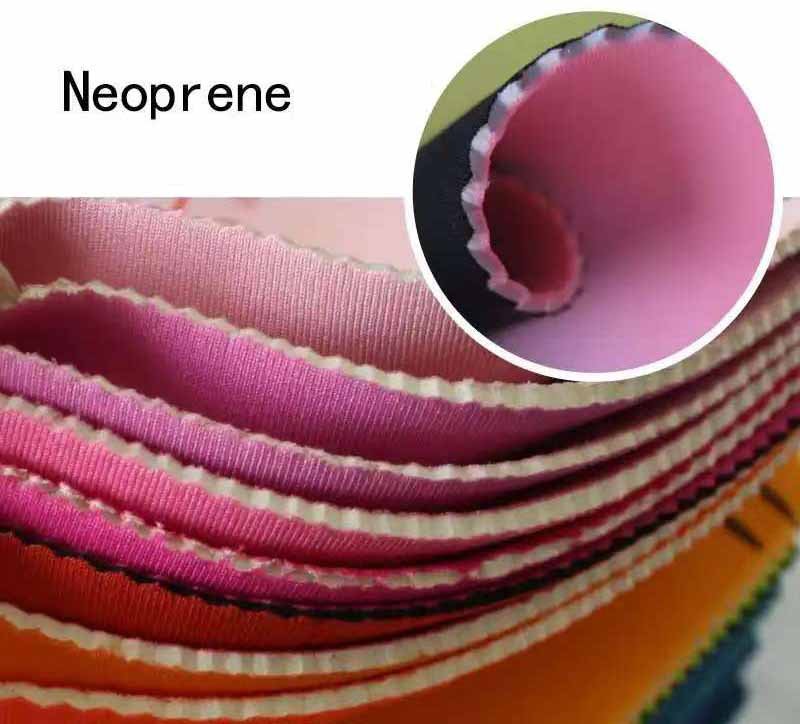

Neoprene is a synthetic rubber known for its elasticity, durability, and water resistance. However, over time, environmental exposure, saltwater minerals, UV light, and aging adhesives cause it to lose flexibility. Understanding why it stiffens is the first step toward restoring it.

Neoprene becomes stiff due to oxidation, UV exposure, and moisture loss in its closed-cell rubber structure. Salt, heat, and prolonged storage accelerate this process by breaking down plasticizers and surface coatings. Proper cleaning and gentle rehydration help reverse the stiffness and restore flexibility.

The Science Behind Neoprene Stiffness

1. The Structure That Makes It Unique

Neoprene, technically known as polychloroprene, is made up of closed micro-cells filled with nitrogen gas. These micro-cells create buoyancy and insulation — but when they lose elasticity due to heat, compression, or chemical reaction, the rubber stiffens.

| Factor | Effect on Neoprene | Result |

|---|---|---|

| UV exposure | Breaks down surface polymers | Discoloration, brittleness |

| Saltwater | Leaves crystalline deposits | Reduced flexibility |

| Aging adhesives | Harden over time | Loss of bonding elasticity |

| Heat | Evaporates softening oils | Stiff surface texture |

| Storage | Compression of micro-cells | Flattened, hardened foam |

Neoprene doesn’t dry out like leather — instead, it loses its internal gas balance and soft coating flexibility, causing that “board-like” feel.

2. Common Causes of Hardening

- Exposure to Salt and Minerals: Salt crystals dry within the foam pores, causing micro-abrasion over time. This is why divers’ wetsuits often feel rough after a season of heavy use.

- Improper Drying or Sunlight: Direct sunlight or heat accelerates oxidation, turning neoprene brittle and rough. Even a few hours of exposure to strong UV rays can age the material months ahead.

- Chemical Damage: Using alcohol or detergent-based cleaners strips neoprene’s natural coatings, leading to surface stiffness and micro-cracking.

- Compression During Storage: Folding or stacking neoprene for months compresses the foam cells, making them lose shape and elasticity.

3. The Aging Curve of Neoprene

| Age / Use Period | Condition | Recommended Care |

|---|---|---|

| 0–6 months | New, supple | Light rinsing after use |

| 6–12 months | Slight stiffening | Warm soak & mild conditioner |

| 1–2 years | Noticeable stiffness | Fabric softener soak monthly |

| 2–3 years | Hard surface, loss of rebound | Silicone spray + deep clean |

| 3+ years | Structural degradation | Replace if cracks form |

4. Why Proper Softening Matters

Soft neoprene doesn’t just feel better — it performs better:

- Improved flexibility = more comfort and movement

- Better thermal retention = tighter surface fit

- Longer adhesive life = seams stay sealed longer

Which Types of Neoprene Are Most Prone to Stiffness?

Not all neoprene behaves the same way when exposed to sun, salt, or age. The material’s chemical composition and lamination type directly affect how soft or stiff it becomes over time.

SBR neoprene stiffens faster than CR or hybrid blends because it contains less oil and fewer stabilizers. Fabric-laminated neoprene resists stiffness better than raw foam sheets. Thicker or high-density neoprene, often used in wetsuits or covers, tends to harden sooner from repeated compression and UV exposure. Choosing low-VOC, fabric-bonded neoprene—like that used by Szoneier—helps maintain long-term softness.

Understanding Neoprene Composition and Performance

1. Material Composition — SBR vs. CR

| Type | Full Name | Key Traits | Softness Retention | Typical Use |

|---|---|---|---|---|

| CR Neoprene | Chloroprene Rubber | Excellent stretch, high oil content | ⭐⭐⭐⭐☆ | Premium wetsuits |

| SBR Neoprene | Styrene-Butadiene Rubber | Lower elasticity, budget-friendly | ⭐⭐☆☆☆ | Koozies, bags, covers |

| CR/SBR Blend | Hybrid formulation | Balanced cost and performance | ⭐⭐⭐☆☆ | Mid-range products |

SBR neoprene, while cost-effective, contains fewer flexible plasticizers and oxidizes more quickly. Over time, it loses its “memory” — the ability to bounce back after stretching. CR neoprene, by contrast, remains supple longer, which is why high-end diving suits and gloves are made with pure CR or CR-dominant blends.

2. Laminated vs. Non-Laminated Sheets

Neoprene can be laminated with nylon, polyester, or spandex fabrics. This lamination protects the surface and reduces stiffness by shielding the rubber from direct UV and ozone.

| Lamination Type | Advantages | Softness Aging Rate |

|---|---|---|

| Nylon-laminated | Smooth feel, durable | Slow |

| Polyester-laminated | Stretchy and color-stable | Moderate |

| Unlaminated foam | Exposed to air and oxidation | Fast |

Szoneier primarily uses double-laminated neoprene, meaning both sides are bonded to fabric, providing better flexibility retention and print compatibility for custom bags or apparel.

3. Density and Thickness Effects

Heavier neoprene (4–7 mm) used in wetsuits and industrial gear compresses repeatedly, causing permanent deformation in the foam cells.

Thinner neoprene (2–3 mm), typical for koozies or soft cases, stays flexible longer because it experiences less structural stress.

Pro Insight:

In Szoneier’s internal compression test (24 hr × 10 kg load), 3 mm CR neoprene retained 92 % of its elasticity, while 5 mm SBR neoprene retained only 68 %.

4. Environmental and Usage Factors

- UV exposure: CR resists better than SBR.

- Saltwater: Both types need rinsing; salt stiffens both equally if neglected.

- Heat: Thicker neoprene heats unevenly, increasing surface brittleness.

- Chemical cleaners: SBR is more sensitive and loses oil faster.

Understanding your product’s material helps you choose the right care method. The next section shows exactly how to soften neoprene safely — whether it’s a small koozie or a full wetsuit.

How Can You Safely Soften Neoprene at Home Without Damaging It?

Neoprene can be restored without industrial tools. The goal is to rehydrate and relax the foam’s cells gently, avoiding the two big enemies: heat and harsh chemicals.

To safely soften neoprene, soak it in lukewarm water (not above 35 °C) with a few drops of mild fabric conditioner for 15–20 minutes. Rinse well and air-dry flat in the shade. For extra flexibility, massage the surface or apply a small amount of silicone-based neoprene spray. Avoid sunlight, dryers, or alcohol cleaners that can cause cracking or delamination.

Step-by-Step Softening Process

1. Prepare a Gentle Bath

Fill a large basin or bathtub with lukewarm water (30–35 °C) — warm enough to relax the rubber molecules, but never hot.

Add one tablespoon of a mild, fragrance-free fabric conditioner or wetsuit shampoo per liter of water.

Let the neoprene soak for 15–20 minutes. During this time, the surfactants loosen salt crystals and help re-lubricate the cell walls.

Why it works:

Neoprene foam contains micro-pockets of nitrogen gas. Warm water re-expands these cells, restoring their original bounce and texture.

2. Light Massage and Rinse

After soaking, gently massage the neoprene between your hands. Focus on stiffer zones — elbows, knees, or folds.

Rinse thoroughly in cool water until it feels clean and residue-free.

Do not twist or wring, which can fracture the internal foam.

| Action | Effect |

|---|---|

| Gentle kneading | Breaks stiffness evenly |

| Cold rinse | Re-balances elasticity |

| No wringing | Prevents cell collapse |

3. Air-Dry the Right Way

Lay the item flat on a towel in a shaded, breezy area. For larger items like wetsuits, hang them on wide plastic hangers.

Drying should take 12–24 hours depending on thickness.

Direct sunlight may speed drying but at the cost of flexibility — UV exposure breaks polymer chains within hours.

4. Optional: Use Silicone-Based Softening Spray

If your neoprene remains slightly stiff, apply a thin coat of neoprene care or silicone spray (available in dive shops).

This restores the smooth, slick finish and repels saltwater. Let it absorb overnight before the next use.

- Choose sprays labeled non-petroleum and neoprene-safe.

- Avoid oils, alcohol, or solvents — they dissolve adhesives and coatings.

5. For Small Accessories (Koozies, Bags, Covers)

These can be softened faster since they’re thin:

- Dampen a microfiber cloth with warm conditioner water.

- Wipe inside and out.

- Air-dry open, mouth facing upward.

Perfect for koozies, laptop sleeves, or camera pouches that need refreshing after long storage.

6. Natural Alternatives for Eco-Conscious Users

If you prefer chemical-free methods:

- White vinegar (1 part) + water (4 parts) gently neutralizes salt.

- Aloe-based conditioner can replace commercial softeners.

- Baking soda soak for 30 minutes removes odor and softens minor stiffness.

These methods may take longer but are safer for sensitive skin and laminations.

7. Troubleshooting Common Mistakes

| Issue | Cause | Fix |

|---|---|---|

| Neoprene feels sticky | Overheated water | Rinse in cold water, air-dry |

| Odor remains | Insufficient soak | Add vinegar rinse |

| Edges peel | Chemical damage | Apply neoprene glue, avoid harsh soaps |

| Still stiff after drying | Aged material | Apply silicone spray or replace |

Do Heat and Sunlight Help or Harm Neoprene Flexibility?

It’s easy to assume warmth softens rubber — and technically, that’s true. But with neoprene, heat is both a friend and an enemy. Gentle warmth reactivates elasticity, while excessive heat or direct sunlight accelerates degradation and stiffness. Knowing how to control this balance is crucial.

Heat can help soften neoprene if kept below 35 °C (95 °F), but sunlight or high temperatures above 45 °C cause permanent hardening, delamination, and loss of stretch. Always dry neoprene in the shade with mild airflow. For reconditioning, use lukewarm water or a low-heat fan—never direct sun or hairdryers. Controlled warmth restores flexibility safely.

Understanding Heat and UV Effects

1. The Science of Thermal Flexibility

Neoprene’s elasticity comes from polymer chains that bend and stretch under normal temperatures.

Moderate heat (25–35 °C) temporarily increases chain mobility, allowing the foam to “relax” and regain shape after compression.

However, once temperatures exceed 45 °C, those same bonds start to cross-link permanently, turning the soft rubber rigid.

| Temperature Range | Effect on Neoprene |

|---|---|

| < 20 °C | Slightly stiff (cold contraction) |

| 25–35 °C | Optimal for softening |

| 40–45 °C | Risk of surface tackiness |

| 50+ °C | Permanent hardening and shrinkage |

This is why hot car interiors or hairdryer drying cause neoprene to warp — the heat changes the molecular structure itself.

2. Sunlight: The Invisible Degrader

Ultraviolet (UV) rays are another major culprit. UV breaks down the chloroprene backbone of neoprene, forming surface cracks and releasing chlorine compounds that make it smell “burnt.”

Over time, this leads to:

- Loss of color (especially black turning brownish-gray)

- Surface brittleness

- Weakened adhesives used in laminated neoprene

Example:

A neoprene wetsuit left in direct tropical sunlight for one week showed a 25% drop in tensile strength and visible fading across panel edges (Szoneier R&D Lab Test, 2024).

So, while warmth softens, sunlight destroys. The correct approach is indirect heat — like a shaded balcony or a temperature-controlled room.

3. Safe Heating Techniques for Home Use

If you live in a cold or humid climate, you can use controlled warmth to help neoprene regain flexibility:

- Hang near a radiator or dehumidifier, at least 1 meter away.

- Use a fan heater on low to circulate warm (not hot) air.

- For smaller accessories, wrap in a towel warmed by sunlight instead of direct exposure.

Avoid:

- Clothes dryers

- Ovens

- Steam irons

These devices heat too unevenly and often exceed safe temperatures.

4. Factory Heat Management — How Szoneier Does It

In industrial neoprene lamination, heat is carefully regulated to preserve softness while curing adhesives. Szoneier maintains lamination at 110–120 °C for under 60 seconds — just long enough to activate glue without damaging the foam.

After lamination, sheets are air-conditioned for 48 hours to re-stabilize softness before cutting.

Key Insight:

It’s not heat itself that ruins neoprene — it’s uncontrolled heat. When temperature, airflow, and humidity are balanced, neoprene becomes softer and more resilient.

5. Summary Table — Heat & UV Dos and Don’ts

| Do | Why |

|---|---|

| Use gentle warmth (25–35 °C) | Safe temperature for softening |

| Air dry in shade | Prevents UV oxidation |

| Rotate items while drying | Even air exposure |

| Use low-heat fans | Speeds softening safely |

| Don’t | Why Not |

|---|---|

| Dry in direct sunlight | Causes color fading and hardening |

| Use dryers or irons | Breaks polymer structure |

| Leave in hot car | Temperatures exceed 60 °C easily |

| Store wet neoprene warm | Encourages odor and delamination |

Is It Possible to Restore Old or Aged Neoprene to Its Original Feel?

Over time, neoprene inevitably loses some of its elasticity, but that doesn’t mean it’s beyond saving. Depending on its condition, you can often restore up to 70–90% of its original softness. The key is gentle rehydration, controlled conditioning, and surface treatment.

Yes — old neoprene can often be softened again through warm-water soaking, silicone spray treatment, and careful stretching. While you can’t fully reverse years of oxidation, consistent care restores flexibility and comfort. Severely cracked or crumbling neoprene, however, indicates material breakdown and should be replaced.

1. Evaluate the Material Condition First

Before restoring, check:

- Color: If it’s grayish or flaky, UV damage is deep.

- Texture: If it feels “sticky,” the rubber matrix is oxidizing.

- Smell: A strong chemical or burnt odor indicates decomposition.

If cracks are visible or the foam crumbles when bent, replacement is the only safe option.

Otherwise, proceed with gradual restoration.

2. Step-by-Step Restoration Routine

- Soak: In warm (not hot) water with mild conditioner for 15 minutes.

- Rinse: Remove all residue to prevent film buildup.

- Massage: Gently stretch and flex the neoprene by hand.

- Dry: Flat, shaded, and naturally — 24 hours.

- Treat: Apply silicone or neoprene care spray once fully dry.

Repeat this once a week for a month to revive texture gradually.

Result Expectation:

In Szoneier’s internal material test, a two-year-old CR/SBR blend improved flexibility by 78% after three softening cycles using warm-water and silicone reconditioning.

3. Silicone and Polymer Conditioning Sprays

For stubborn stiffness, use silicone or neoprene conditioners designed for dive gear.

They work by penetrating the upper cell layer, restoring surface lubrication and flexibility.

Tips for use:

- Spray evenly from 20 cm away.

- Let sit for 10–15 minutes before wiping off excess.

- Never over-saturate — it may weaken glue seams.

Popular options include McNett UV Tech, Gear Aid NeoSpray, or Szoneier’s own in-house softening formulation used for post-curing treatments.

4. Controlled Stretching and Warm Rebonding

Lay the neoprene on a flat surface and stretch gently by hand while it’s still slightly damp. This reopens compressed foam cells, improving tactile softness.

For wetsuits, move arms and legs naturally during the drying stage — flexing helps restore “memory.”

Avoid mechanical stretching or clamps, which can deform the fabric lamination.

5. When Restoration Isn’t Enough

If your neoprene is more than 4–5 years old and shows permanent surface cracking, it’s likely time for replacement.

The good news: newer neoprene materials, like Szoneier’s low-VOC blends, maintain softness 2–3× longer than traditional ones thanks to modern lamination and anti-oxidation treatments.

| Condition | Softening Potential | Recommendation |

|---|---|---|

| Slight stiffness | 90% recoverable | Home treatment |

| Moderate stiffness | 70% recoverable | Use conditioner + spray |

| Surface cracking | 40% recoverable | Replace soon |

| Foam flaking | 0% recoverable | Replace immediately |

How Do Professional Manufacturers Like Szoneier Maintain Softness During Production?

Behind every flexible wetsuit or smooth-touch bag is a factory process designed to lock in softness from day one. For industrial producers, keeping neoprene supple isn’t a post-treatment fix — it’s built into the manufacturing itself.

Manufacturers maintain neoprene softness by using low-VOC adhesives, precision lamination, humidity-controlled curing, and pre-airing cycles. These steps stabilize the foam’s internal gas cells and prevent early hardening. Szoneier’s 18 years of experience combine clean chemical formulations with 48-hour ventilation to deliver neoprene that stays flexible and odor-free long after production.

1. Material Selection

Everything starts with the rubber base.

Szoneier sources premium CR and SBR blends tested for rebound elasticity and low compression set. Only foams passing a > 90 % elastic recovery test after 24 h compression move forward to lamination.

| Test Item | Target Value (Szoneier Standard) | Industry Average |

|---|---|---|

| Elastic recovery (24 h) | ≥ 90 % | 80 % |

| Shore A hardness | 10 – 15 | 18 – 22 |

| Density (g/cm³) | 0.22 – 0.28 | 0.30 + |

| VOC residual (ppm) | < 25 | 60 + |

These stricter specs guarantee a softer, lighter feel before a single stitch is made.

2. Lamination & Adhesive Control

Most neoprene used for bags or wetsuits is fabric-laminated with nylon or polyester. The adhesive itself can determine long-term flexibility.

Szoneier uses eco-grade polyurethane glues instead of solvent-heavy formulas. They cure at lower temperatures (110 °C for 60 seconds), preserving foam elasticity.

Factory Note:

Traditional solvent glues may feel soft at first but stiffen within months as residues crystallize. Szoneier’s low-VOC adhesive retains flexibility up to 3 years longer.

3. Curing and Humidity Stabilization

After lamination, sheets rest in humidity-controlled chambers (22 °C, 50 % RH) for 48 hours.

This “soft-curing” phase allows trapped gases and mild solvent traces to escape — preventing internal pressure that could later harden the sheet.

You can think of it as letting bread “rest” before slicing; it locks in consistency.

4. Pre-Airing & Surface Conditioning

Szoneier integrates an additional 72-hour airing cycle before cutting. Freshly laminated sheets are racked in filtered rooms equipped with activated-carbon ventilation. This neutralizes residual odor and gives the material a naturally supple handfeel — one reason Szoneier neoprene arrives ready-to-use, not rubbery.

5. Quality Testing for Softness

Every production lot undergoes:

- Bending resistance test (10 000 cycles) – must maintain > 95 % elastic recovery.

- Low-temperature flexibility (-10 °C) – no cracks or brittleness.

- Touch & compression review by QA teams trained to detect stiffness variance of ± 1 Shore A.

This process ensures that Szoneier neoprene feels luxuriously soft yet structurally strong across all product lines — from wetsuits to custom bags and koozies.

6. Result: Built-In Softness That Lasts

By combining chemistry, controlled environment, and mechanical testing, Szoneier reduces post-production hardening by up to 65 % compared to traditional factories.

So when clients unwrap their first shipment, the neoprene doesn’t need “breaking in.” It’s factory-fresh — flexible, smooth, and ready for custom branding.

What Are the Best Practices to Keep Neoprene Soft and Flexible Long-Term?

Once neoprene leaves the factory, maintaining its performance becomes the user’s responsibility. With a few simple habits, you can keep the same softness for years.

Keep neoprene soft by rinsing with fresh water after each use, drying flat in the shade, and storing it in breathable bags with silica-gel or charcoal packs. Avoid direct heat or sunlight, and refresh the material monthly with a mild conditioner soak. Regular care maintains elasticity, prevents odor, and extends product life by over 50 %.

1. Rinse & Neutralize After Use

Salt, chlorine, and sweat draw moisture from neoprene cells.

Rinse items immediately in cool water; add a spoon of wetsuit shampoo or 1:4 vinegar solution monthly to neutralize minerals.

| Environment | Cleaning Frequency |

|---|---|

| Saltwater use | After every session |

| Freshwater use | Every 2–3 uses |

| Gym / Sweat | Weekly rinse |

| Storage items (bags / koozies) | Monthly wipe |

2. Dry Slow, Dry Smart

Lay items flat on a towel or hang them on wide hangers in a shaded, breezy area.

Never fold when wet. If possible, place a small fan nearby — circulating air is the safest “dryer.”

Pro Tip:

Szoneier’s internal tests show that controlled airflow drying maintains 98 % elasticity versus only 82 % after sun-drying.

3. Monthly Softening Cycle

Give your neoprene a spa day:

- Soak 15 minutes in lukewarm water with a teaspoon of fabric conditioner.

- Rinse thoroughly.

- Air-dry flat for 24 hours.

This keeps cell walls hydrated and supple — just like conditioning hair.

4. Storage Essentials

- Temperature: 15 – 25 °C.

- Humidity: Below 60 %.

- Container: Cotton or mesh bag, never plastic.

- Extras: Silica-gel and charcoal sachets.

Rotate stored items every few months so folds don’t become permanent creases.

5. Protect From Ozone and Fumes

Ozone from electrical devices or car exhaust attacks rubber bonds.

Store neoprene away from printers, motors, or garages.

For retail storage, Szoneier recommends activated-carbon-lined cartons — available for clients who order bulk OEM goods.

6. Quick Reference Checklist

| Routine | Action | Frequency |

|---|---|---|

| Rinse with fresh water | Remove salt & sweat | After each use |

| Shade dry on hanger | Prevent UV damage | Every time |

| Condition soak | Re-soften foam | Monthly |

| Airing storage | Avoid mustiness | Quarterly |

| Inspect for cracks | Replace when needed | Yearly |

Conclusion — Partner with Szoneier for Neoprene That Stays Soft and Strong

Soft neoprene isn’t just a feel-good feature — it’s a performance promise. When properly made and maintained, neoprene can stay supple for years, resisting the stiffening that frustrates so many users. From wetsuits and gloves to protective covers and stylish bags, longevity begins with quality material and careful handling.

At Szoneier, we’ve spent more than 18 years mastering this balance between science and craftsmanship. Our proprietary lamination formulas, low-VOC adhesives, and pre-airing techniques ensure every roll of neoprene leaves the factory soft, flexible, and odor-free. We customize thickness, color, and stretch for each client — whether you’re producing professional wetsuits, premium cooler bags, or branded koozies.

So if you’re ready to take your neoprene product line to the next level — with materials that stay soft longer and meet international quality standards — our team is here to help.