Neoprene isn’t just foam—it’s a wonder fabric with secrets hidden in its thickness. Imagine shopping for a sleek neoprene laptop sleeve or a cozy wetsuit—thickness determines everything: warmth, flexibility, durability. But how thick should neoprene fabric be for your product? Too thin and it feels flimsy; too thick and it loses comfort or becomes overly heavy. As a customer or brand looking to order OEM or private label neoprene items, understanding the right gauge isn’t just nice—it’s critical.

What is the standard thickness of neoprene fabric?

Neoprene thickness typically ranges from 1 mm (~0.04 in) to 7 mm (~0.28 in) for most soft goods and sportswear. Thin neoprene (2-4 mm) suits items like bags, sleeves, accessories; mid-range (4-6 mm) balances insulation and flexibility; thick neoprene (6-7 mm or more) is used for wetsuits and high-performance gear. Laminated varieties may add extra layers for fabric backers or coatings, altering effective thickness and feel.

To hook you in: I once visited a small surf brand client who ordered a “standard 5 mm” neoprene wetsuit — but complained about stiffness. We measured, and the fabricstock was actually 7 mm thick! That single mm change raised stiffness so much customers wanted cutouts at joints. That’s when I realized: gauge matters more than you think. Stay with me — by the end you’ll know exactly how thick neoprene should be for your product type, how to test it, and how thickness influences cost, feel, and performance.

What Is The Standard Thickness Of Neoprene Fabric?

Standard neoprene commonly ranges from 1–7 mm, depending on application. Thin gauges (1–3 mm) are used for lightweight accessories; mid-range (4–6 mm) for sportswear and insulation; heavy/thick gauges (6+ mm) for full wetsuits or high thermal protection. Laminated backers or coatings may increase overall thickness beyond foam.

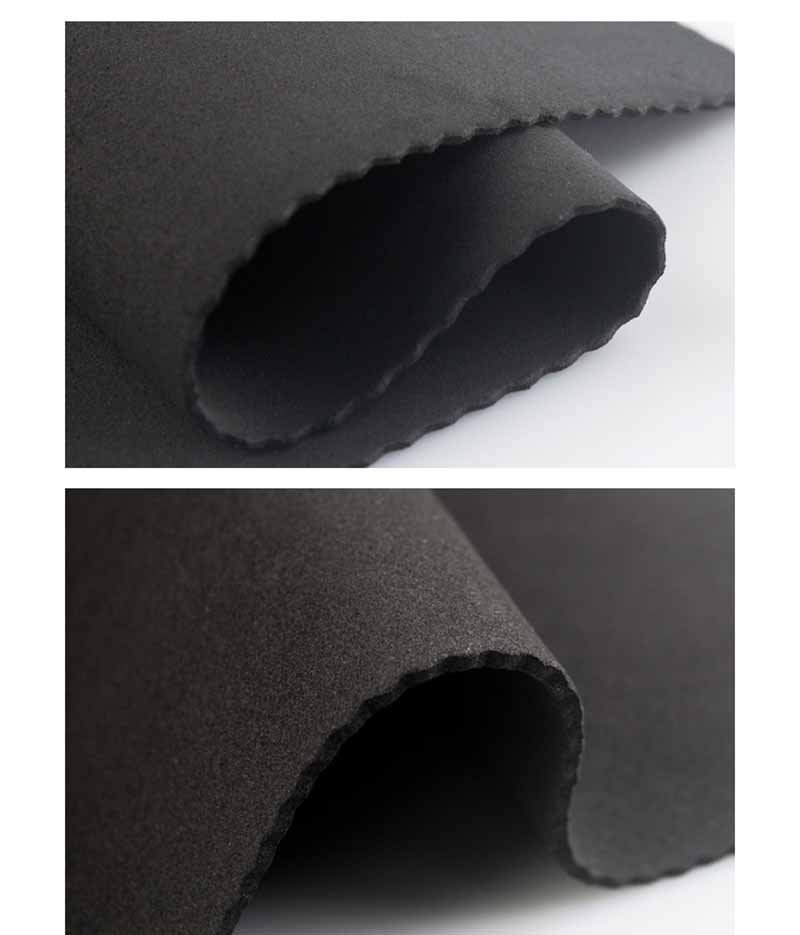

Neoprene foam is typically manufactured as a closed-cell rubber material, often called CR (chloroprene rubber), formed by foaming agents. The exact thickness arises from factory molds or calendering processes. Here are several factors and detailed breakdowns:

1.Production processes & raw foam sheets:

Unbacked neoprene begins as foam sheets, often cut in standard thicknesses: 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 7 mm. Thicker sheets (8–10 mm or more) are used in specialized cold-water wetsuits, dive hoods, or industrial applications. The thinner end (~1 mm) serves light paddling gear, liners, or protective covers. The middle (3-5 mm) is a “sweet spot” for many OEM uses: bags, sleeves, snugs, straps. These foam sheets can be laminated to fabric for added durability; fabric backers (nylon, polyester) typically add 0.3-1 mm, depending on weave and finish.

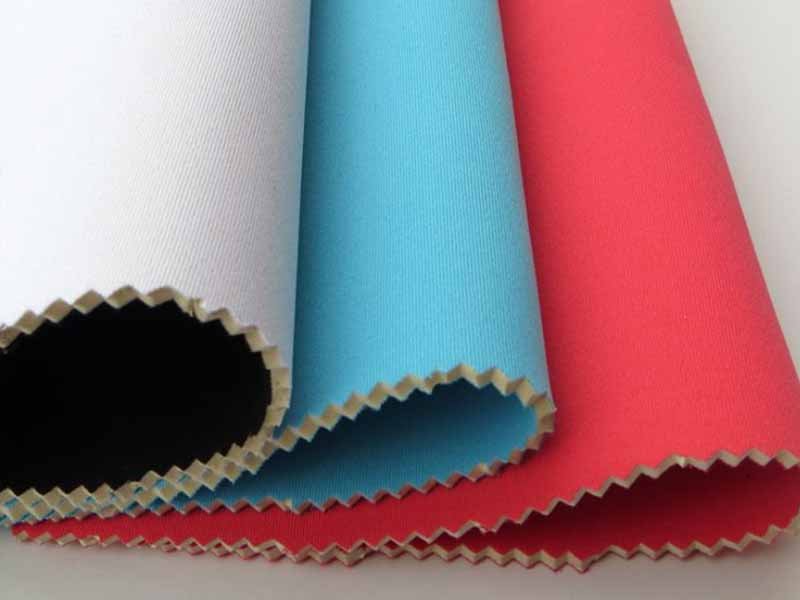

2.Laminated vs raw neoprene:

Many commercial neoprene products you touch have a fabric on one or both sides—either smooth-skin, fleece, nylon, or polyester. Backed neoprene feels stiffer and bulkier; a 3 mm foam sheet with a thick fleece lining may feel more like 4 mm due to the fabric. When quoting thickness, many suppliers quote just the foam, others quote foam + backer. Always clarify. It’s common for differences of 0.5 mm or more to creep in because of lining or adhesive layers.

3.Tolerance and measurement error:

In manufacturing, thickness is rarely perfectly uniform across the entire sheet. Foam compression during storage, tearing, or heating can lead to small warps. Suppliers often allow tolerances of ±0.3-0.5 mm for thinner sheets (<4 mm), and ±0.5-1 mm for thicker ones. Testing spots across the sheet (corners, center) help ensure uniformity. Also, the measurement tool matters—a digital caliper vs. foam gauge under pressure will yield different readings.

4.Cost implications of thickness:

Thicker neoprene foam = more raw rubber, more material cost, more shipping weight, potentially slower curing/drying times, more waste in trimming. For OEM/ODM, thickness jumps may push MOQ or price tiers. For example, a 2 mm neoprene bag may cost 15-30% less material cost than a 5 mm version, everything else equal. Also, storage and cutting thicker sheets require more robust machinery and handling.

5.Choosing the right standard thickness:

As a buyer, ask: what is the end-use? If your product needs to protect electronics or keep things warm, 4-5 mm with back lining may be enough. If its for diving 5+ m depth or cold water, go for 6-7 mm or more. Conversely, for travel sleeves, light covers, or fashion bags, 2-3 mm gives flexibility and lighter weight. Always ask the supplier to send you sample swatches so you can feel the difference.

Which Neoprene Thickness Fits Different Applications?

Different products demand different neoprene gauges: bags, sleeves usually use 2–4 mm for pliability; koozies & protective covers around 3–5 mm; sports braces or supports prefer 4–6 mm for balance of support; wetsuits & water sports gear often 5-7 mm or layered zones for thermal and mobility performance.

When customizing neoprene products, matching thickness to use-case is a key decision. Let’s examine categories and their ideal gauges with pros and cons.

Bags, laptop sleeves, fashion accessories

For items like tote bags, laptop sleeves, camera cases, or gym bags, thinner neoprene—typically 2-4 mm—is preferred. Why? Thinner materials give flexibility, ease of stitching, lighter weight, less bulk. A 3 mm neoprene sheet with a nylon backer can offer structure but still foldable. Thicker options (5+ mm) may start to feel bulky, making seams harder to sew and the finished item heavier (shipping cost rises). Also, thinner neoprene helps in printing or embossing logos, reducing distortion.

Drink koozies, bottle wraps, protective covers

These items don’t need stretch for body movement but do need insulation and grip. Thickness of 3–5 mm tends to balance between insulating ability and flexibility. A 4 mm piece keeps beverages cool or warm, resists deformation when holding, yet isn’t so heavy it’s impractical. Also, if you add lining or fabric backer, the effective thickness increases; so many OEMs design with foam + lining to get both heat retention and durability.

Sports braces, medical supports

For braces or supports (for knees, elbows, wrists), you need enough thickness to cushion joints, resist wear, but also preserve range of motion. 4-6 mm is often optimal. Too thin, and you don’t get support; too thick, and joint movement is compromised. Also, stitching method matters: flatlock or bonded seams can handle 4-6 mm; but gussets, openings, and heat seal methods become more complex with thicker foam.

Wetsuits, dive/surf gear, thermal protection

Here, thermal protection is critical. Thickness of 5-7 mm is common for full-body suits in colder waters (~15-20 °C or lower). For tropical or warmer water, zones may vary: a torso panel of 5 mm for warmth, with limbs at 3-4 mm for mobility. Also, special sections (knees, elbows, shoulders) may get reinforced or thickened. Extra lamination (smooth skin or fleece) helps wind resistance and comfort. But increasing thickness beyond 7 mm often yields diminishing returns: flexibility suffers, entry/exit in suits gets harder, weight up, and cost up.

Other specialized uses

Neoprene covers, wraps, industrial pads may require thicker gauges (8-12 mm or more) or multi-layer builds. For example, industrial insulation pads or acoustic dampening panels. Also, neoprene wetsuit boots, hoods, gloves may combine thinner panels (2-4 mm) with thicker portions (5-7 mm) in key areas. This patchwork zone design helps maintain movement while protecting sensitive zones.

Balancing features vs cost

While thicker neoprene typically offers more protection, bulk, and insulation, it also costs more—material, shipping, tooling, and labor. For many clients of Szoneier, optimizing thickness to application saves cost without sacrificing performance. For instance, choosing 4 mm with back lining rather than 6 mm pure foam might hit the sweet spot: good warmth, lighter product, lower price, easy sewing, faster lead time.

How Does Thickness Affect Performance?

Thickness impacts warmth, insulation, buoyancy, flexibility, durability, and weight. Thicker neoprene retains heat better and cushions more, but is heavier, less flexible, and may compress. Ideal performance often comes from balancing thickness with density, backer type, seam method, and zones of use.

Thickness isn’t the only performance factor; it works in tandem with foam density, backing, seam design, and intended usage. Let’s unpack the trade-offs, performance gains, and potential pitfalls.

Thermal insulation & warmth

Closed-cell neoprene traps air bubbles; thicker foam means more trapped air and better insulation. But the rate of heat loss depends also on water temperature, how well the suit seals water entry points, and how good the backer is (smooth skin, fleece, etc.). For example, a 5 mm suit with fleece lining feels warmer than a 6 mm with a smooth skin inside, because fleece retains heat better next to skin. Also, too thick foam in areas with movement causes cold water flushing, which reduces insulation more than thickness benefit.

Flexibility, mobility & comfort

As thickness increases, flexibility drops. For many wearable neoprene products (wetsuits, braces, gloves), joint areas or limb zones are often thinner or pre-curved. 2-3 mm or 4 mm at joints helps mobility; 6-7 mm if in torso can stay thicker. Users often complain: “my thick wetsuit feels restrictive when I paddle” — meaningful feedback. So design usually zones material: thick where you need warmth/impact, thin where you want motion.

Buoyancy & flotation

Thicker neoprene gives more buoyancy—but this may or may not be desirable. For diving, buoyancy must be compensated via weights or design. For water sports gear, too buoyant can affect natural motion. For non-water gear (bags, sleeves) it doesn’t matter much, but thicker foam may cause floating when wet—a factor in bag design or outdoor gear.

Weight, bulk & sewing difficulty

Material weight scales roughly with thickness × density × area. Heavier or thick neoprene increases shipping cost, wearable fatigue, bulk when stored or folded. Also, thicker foam is harder to stitch—needle penetration, thread tension, seam type, seam thread density need adjustment. Equipment needs to handle thicker folds — double layers + backer can add stack height. In bags or covers, bulky seams show more, require more finishing.

Durability, compression resistance, and wear

Thicker foam tends to resist compression, tears, and abrasion longer. But density matters: a low-density thick neoprene may deform under load, compress and lose cushioning quicker. Also, coatings and backers help protect foam surface; without proper backing or finishing, even thick neoprene will degrade faster. Seams are high-stress points: thicker panels place more strain on stitching and bonding adhesives—quality of seamwork matters as much as thickness.

Electric cost vs performance trade-off

As thickness increases, cost rises—material cost, manufacturing time, yields drop due to trimming waste, shipping weight. For many clients, the marginal benefit from going from 5 mm to 7 mm is small compared to the cost increase, especially if only portions (not whole product) need high thickness. Smart engineering: zone-thickness, differential backers, or combining thickness with better lining may give better ROI.

How To Measure Neoprene Thickness Accurately?

Use precise tools like digital calipers or thickness gauges; measure in multiple spots (corners, centre); avoid compressing foam; understand whether you’re measuring foam alone or foam plus backing; refer to ASTM/ISO standard methods for repeatable results.

Accurate measurement matters: your product quality, customer satisfaction, reputational risk all depend on making sure thickness specs are met. Here’s how to ensure you get correct measurements, consistent quality, and reliable supplier claims.

Tools & measurement best practices

- Digital calipers: Great for unbacked sheets, but risk compressing foam—use minimal pressure.

- Thickness gauges: Specifically made for soft materials, distribute contact evenly.

- Micrometer with flat foot: Helps when measuring laminated neoprene to avoid fabric bunching. For any tool, calibration matters. Always zero before use. Use consistent measurement spots, typically 3-5 per sheet: top left, top right, bottom left, bottom right, center.

Avoid compression errors

Foam compresses under pressure: if you press too hard, measurement will read lower than real thickness. This is especially relevant for thin sheets. Let the tool rest gently; measure multiple times and average. Ensure the foam is not pre-compressed (stored under load). Also ensure environment is flat and stable—no curling or folds that distort measurement.

Measuring laminated neoprene

When foam is backed with fabric (nylon, polyester, terry, fleece, smooth-skin), measurement includes foam + backer + adhesive or lamination layer. Sometimes the backer is wavy or uneven—folds, creases, or glue thickness make thickness vary. Measure at spots where backer lies flat. Clarify with supplier whether quoted thickness is foam only or total laminate. If you have fabric on both sides, note both layers—front and back.

Standards & tolerances

Use standards like ASTM D1056 (cellular rubber specifications) or ISO 845 (density of cellular plastics & rubbers) to define density, compression, but for thickness tolerances there are less universal standards—many factories adopt ±5-10% for thin foam, ±7-15% for thicker sheets. Put tolerances into purchase orders: e.g. “5 mm ±0.5 mm (foam only)” and note if backer thickness is excluded/included. This avoids disputes at inspection.

Quality Control (QC) in production

During production, incoming raw foam sheets should be sampled; laminated panels also. At cutting and sewing, monitor zones: if sewing multiple layers, stack thin scraps and measure stack height. Use gauge pads or templates. Before shipment, random units should be measured (e.g. 5% or more) to ensure consistent thickness. Document measurements—images and records help if customer asks for proof or when exporting.

Why measurement affects performance & cost

Thickness mis-measurement leads to products that feel too stiff, too floppy, or don’t perform as promised. It may also increase cost unexpectedly (if actual material used is more than calculated). Or lead to unhappy end-users (too cold, too heavy). For custom OEM/private label products, setting up clear specs and testing early (pre-samples) avoids costly re-work or returns. Szoneier factory offers free sample swatches so you can verify thickness and feel before full production.

Do Laminations And Coatings Change Thickness?

Yes — backers (nylon, polyester, fleece, terry, smooth-skin), coatings, and adhesives add thickness beyond foam. A 3 mm foam may feel like 4 mm or more once fabric and lamination are added. Always confirm whether quoted thickness includes lamination or not.

Laminations, coatings, backers all play a big role in the overall thickness, feel, durability, and cost of neoprene products. Here’s a detailed view of what to watch out for, and how these additions change things.

Types of backers & their thickness contribution

- Smooth-skin or skinner layer: often 0.2-0.5 mm, gives water resistance and sleek look.

- Fleece lining (brushed inner): 0.5-1.5 mm depending on pile depth. Adds warmth and comfort.

- Terry cloth or toweling: 1-2 mm; often used in towel-like garments or wraps. Bulkier, more absorbent.

- Nylon or polyester knit: lighter, thinner—0.3-0.8 mm; improves abrasion resistance. When foam is bonded on both sides (double-face lamination), these backers are present on both faces, potentially doubling the added bulk.

Coatings and texture effects

Beyond fabric backers, coatings like PU (polyurethane), PVC, or printed/embossed finishes affect thickness, sometimes in less visible ways. PU coating may add 0.1-0.3 mm, but if thick or layered, more. Embossing compresses foam unevenly—raised areas may show more thickness, depressed areas less. Adhesives used in lamination also contribute; glue layer thickness can vary, especially if lamination is done in large batches with less control.

Effective vs nominal thickness

Nominal foam thickness is what many suppliers will provide. Effective thickness = foam + backer + coating. For performance (thermal, bend, seam sewing), effective thickness is what counts. When you hold a finished good, you feel the combined thickness and stiffness. A nominal 3 mm foam with fleece inner and nylon outer will behave differently than raw 3 mm foam.

Impact on sewing, shaping, and comfort

The more layers (foam + backer + coating), the thicker the stack where seams meet. This affects which sewing machines, needles, threads you need. Thicker stacks can lead to needle skipping or heavy stress at edges, especially with curved or multi-layered joints. Also, padding and lining that is thick or bulky may reduce comfort in wearable items, cause chafing where seam bulk is high.

Cost & lead-time implications

Lamination and coating steps add process time, require coated fabric or treated sheets, more drying or curing, sometimes more waste. These raise cost. Turnaround times may lengthen if certain backers or coatings are in short supply. Also, color matching fabrics, finishes, or special texture coatings often increase MOQ or sampling costs.

Design strategies

Smart product designers balance lamination: use backers only where needed (e.g., outer surfaces for abrasion, inner surfaces for comfort), leave non-critical panels raw if possible. Use zone-lamination: reinforce high-wear zones with thicker backer, leave other parts lighter for flexibility. Communicate with supplier early (like Szoneier) about backer types you want, whether surface finishes are matte, shiny, printed, or smooth-skin. Try sample pieces so you can touch and test before approving bulk production.

Is Thicker Neoprene Always Better?

Not always. Thicker neoprene often gives more insulation and durability, but brings downsides: more weight, less flexibility, higher cost. For many products, optimal performance comes from balancing thickness with zones, backers, seam design, and intended user comfort.

The assumption that “thicker = better” is common but flawed when you examine real use cases, user feedback, and cost trade-offs. Let’s explore both sides and help you decide what’s truly “better” for your product.

Advantages of thicker neoprene

- Thermal retention: More foam traps more air; more insulation especially in cold water or cold climates.

- Durability & protection: Thicker material resists puncture, abrasion, impacts. Good for protective gear or rugged usage.

- Structural stability: Heavy items (e.g. tool wraps, reinforced bags) benefit from thicker neoprene to hold shape.

- Buoyancy where needed: For aquatic sports gear, added floatation may help safety or performance.

Drawbacks & trade-offs

- Weight & bulk: Thicker products weigh more; shipping and packaging costs escalate. Heavy neoprene gear can fatigue users.

- Reduced flexibility & comfort: Moving in thick neoprene at joints becomes stiff; bulky seams may chafe or feel uncomfortable.

- Cost overhead: Material cost, cutting, lamination, shipping all go up. Sample costs rise; waste from trimming thick panels is higher.

- Reduced aesthetic finish: Thicker foam + thick backer + coatings = more visible seams, harder to get slim silhouettes or elegant drape in fashion accessories.

Balancing act: zones, seam design, backer choice

Many high-end wetsuits and gear use zone design: thick panels in torso/back for insulation, thinner in arms/legs. Seam types (flatlock, blind stitch, bonded seams) affect flexibility. Using stretch backers, smooth skin surfaces, or pre-bent cuts can help offset stiffness. Also, selective lamination only where needed (outer shells) reduces weight.

Real world feedback & case studies

One of our clients wanted a cold-water paddle jacket. They thought 7 mm neoprene would be “warmer.” When they wore it, the added thickness impeded arm lift—making paddle strokes awkward. We redesigned: layered 5 mm torso with 3 mm sleeves. Customer got warmth where needed, flexibility in motion. Similarly, for neoprene bags: going from 4 to 6 mm made edges thick; zippers hard to sew; shipping cost spiked. Many customers prefer slightly lighter products that feel more “livable.”

Environmental & sustainability considerations

Thicker neoprene uses more raw materials and energy in foam production. More waste in trimming. Heavier goods ship heavier (higher carbon footprint). Some clients concerned about limit excess. So, “better” sometimes means “just enough” not “max thickness.”

When thicker is clearly better

In cold water diving, surf, wetsuits below 15°C, or in usage with high abrasions (knees, elbows), thicker panels make sense. Similarly, for protective gear for industrial or medical use, thickness may contribute safety standards. Or, for insulation panels, covers, and industrial wraps.

Are There Standards For Thickness & Tolerances?

Yes. Standards like ASTM D1056 and ISO 845 can define cellular rubber quality, density and some compression metrics. Tolerances commonly are ±5-10% for thin neoprene (<4 mm), ±7-15% for thicker. Manufacturers should specify whether thickness is foam only or foam plus backing.

Standards and clear tolerance definitions protect both buyer and manufacturer. Whether you are ordering private label neoprene goods or OEM for big-brand, clear specifications matter. Let’s go through what exists, what to watch for, and how to write good spec sheets.

Relevant standards & what they cover

- ASTM D1056: Deals with specifications for rubber cellular materials; addresses physical properties like compression, tensile strength, hardness, etc. Thickness is indirectly addressed through compression under load.

- ISO 845: Defines density measurement of cellular plastics & rubbers. While it doesn’t mandate thickness, it helps relate thickness and density to performance.

- Other relevant: standards for water absorption, thermal conductivity, seam water tightness etc., depending on product category.

Common tolerance benchmarks

For thinner foam sheets (<4 mm), factories often allow ±0.3–0.5 mm (~5-10%) tolerance. For thicker foam or laminated pieces (5-7 mm+), tolerances widen: ±0.5-1 mm or ±7-15%. In purchase orders, specify: “Nominal thickness: 5.0 mm ±0.5 mm (foam only), laminated with fleece etc. backer adds approx 1.2 mm.” Confirm whether supplier’s measurement includes lamination.

Specifying specs in purchase orders or tech packs

Good spec sheet should contain:

- foam thickness (mm)

- backer type and thickness

- coating or finish info

- density / weight per m²

- hardness (Shore A or similar)

- flexibility / bend test, compression recovery

- tolerance allowed in thickness and uniformity

- sample required for approval

Include measurement points (corners, center) and acceptable minimums. For finished good, also specify “effective thickness” including linings.

Inspection / QC & compliance

Standards help when doing quality inspections. When importing into certain markets, material safety standards (REACH, CPSIA, OEKO-TEX) may require documentation. Some clients demand lab reports. For thickness, inspector may require measuring samples with calibrated tools. Also check for consistency across production runs. If thickness varies too much, performance (warmth, fit, durability) suffer.

Industry examples

| Product Type | Typical Nominal Thickness | Tolerance (%) | Foam Only vs Total Laminate |

|---|---|---|---|

| Laptop sleeve / bag | 3 mm | ±10% | Foam only, backer adds ≈0.8 mm |

| Drink koozie | 4 mm | ±8% | With single backer and coating |

| Sports brace / support | 5 mm | ±10% | Foam + fleece inner/backer |

| Full-wetsuit in cold water | 6-7 mm | ±10-15% | Foam + neoprene lining, smooth skin |

Why tolerances matter to the buyer

Slight mis-thickness can cause product rejection, returns, or complaints. For example: stiff wetsuit joints, tight watch straps, zippers that misalign, temperature underperformance. In bag goods: bulk seams, zipper misfits. Specifying tolerances avoids surprises. Szoneier, with its extensive neoprene R&D and manufacturing experience, ensures tight control and transparency. We provide sample panels with measured readings, and our clients often report high satisfaction with consistency.

How Do MOQ, Cost, And Lead Time Vary With Thickness?

As neoprene thickness increases, MOQ, material cost, shipping weight, tooling needs, and lead time all tend to increase. Thinner gauges are cheaper and faster; thicker or laminated panels add time and may require higher minimums. Szoneier offers low MOQs, quick sampling, and transparent pricing per thickness band.

Understanding cost & lead time implications of thickness is essential when planning new neoprene product lines or customizing existing designs. Here’s a deeper look at what adds up, and how Szoneier helps manage these trade-offs.

Material cost & weight factors

Neoprene foam cost scales with volume: thickness × area × density. For example, compare 3 mm vs 6 mm foam for a product cover of 1 m²: 6 mm uses double the foam volume → roughly double the foam cost, plus more cost in lamination, handling, shipping. Also, thicker foam weighs more, increasing shipping cost out of China (or from your factory to final destination). Bulk orders of thicker materials may need more robust packaging.

MOQ (Minimum Order Quantity) effects

Thicker foam or special laminations often require specialized production runs, specific molds or cutting dies, special backers, etc. These setups cost more. Therefore, manufacturers usually require higher MOQs to amortize those fixed costs. For standard thin gauges with common backers, MOQs tend to be lower. At Szoneier, we understand many foreign small-to-mid buyers don’t want large MOQs, so we maintain shared foam stock, commonly used thicknesses, and backers to enable lower MOQs for customized orders.

Sampling & prototyping lead time

Samples are crucial to feel product, test seams, and judge performance. For thicker materials and special linings/coatings, sample preparation takes longer. Thicker laminations need drying times, backer fabric sourcing, more finishing. At Szoneier, free sample swatches are provided, but special sample builds (full product) may take a few extra days when thickness or backer is non-standard.

Production & tooling considerations

Cutting thicker, laminated panels requires different tooling (e.g. knives, dies), sometimes higher compression forces, heavy duty presses. Sewing machines need stronger needles, more powerful motors to handle multi-layer stacks. These increase the per-unit labor cost and may slow down output. Thicker materials often lead to slower stitch times, more hand finishing. All that factors into lead time.

Shipping & packaging weight

Heavier products cost more to ship. Also, thick neoprene items may need bulkier packaging or extra protection. Logistics costs (freight, air or sea) can take sizable chunk of margin. Some clients underestimate this and think all price difference is material cost, but freight often shifts profit margins when thickness increases.

How Szoneier helps minimize these costs & lead times

| What we Do | Benefit to Client |

|---|---|

| Keep stock of popular foam gauges & backer fabrics | Low MOQs even for mid-thickness items |

| Provide free design & prototyping | Helps you try before you commit to bulk orders |

| Strong QC and measured sample panels | Prevents returns and adjusts expectations early |

| Efficient lamination & cutting in-house | Faster turnaround, less dependency on external suppliers |

| Transparent price per square meter/thickness band | You can calculate cost vs performance trade-off early |

Conclusion

Neoprene fabric thickness isn’t just a number—it defines product feel, performance, cost, and customer satisfaction. Getting the right thickness for your application—whether it’s a breathable bag, a wetsuit, a cozy koozie, or protective gear—can make all the difference. Over-specifying adds weight, cost, stiffness; under-specifying sacrifices insulation or structure.

If you are looking to develop a custom neoprene product—whether it’s a private label bag, a custom wetsuit, accessories, or anything in between—Szoneier is ready to help. With over 18 years of R&D and manufacturing experience, full capability for customization, low MOQs, fast sampling, free design services, and 100% quality guarantee, we can work with you to choose the optimum thickness, backers, finishing, and delivery timelines.