Custom neoprene Bags Manufacturer

With 18+ years of expertise, Szoneier specializes in custom neoprene bags manufacturing—offering OEM/ODM services, low MOQ, free design, rapid sampling, and global shipping. Our factory delivers high-quality, fully customizable neoprene lunch bags, tote bags, wine bags, and more, ensuring durability, style, and fast turnaround for brands and wholesale buyers worldwide.

Private Label Neoprene Bags for your customization

Szoneier offers private label neoprene bags with full customization options for global brands and wholesale buyers. From tote bags and travel bags to gym and cooler bags, our factory delivers durable, waterproof, and stylish designs with your custom logo. Enjoy free design support, low MOQ, fast sampling, and short lead times—making it easy to launch your own private label neoprene bag collection with guaranteed quality and flexible OEM/ODM solutions.

Neoprene Backpack

Neoprene Beach Bags

Neoprene Crossbody Bags

Neoprene Duffle Bag

Neoprene Laptop Sleeves

Neoprene Lunch Bags

Neoprene Makeup Bags

Neoprene Messenger Bags

Neoprene Pencil Case

Neoprene Phone Bags

Neoprene Pouch

Neoprene Purse

Neoprene Pencil Case

Neoprene Tote Bags

Neoprene Waist Bags

Neoprene Wine Bags

manufacturer Categories

Get A Free Sample Now

Why Choose Neoprene bags for business?

Choosing neoprene bags for your business means combining style, durability, and functionality in one product. Known for their lightweight, waterproof, and shock-absorbing properties, neoprene bags are perfect for travel, fitness, retail, and promotional markets. With Szoneier’s OEM/ODM services, custom logos, and low MOQ options, businesses can create unique, high-quality neoprene bags that enhance brand visibility while meeting global buyers’ demands for versatility, fast delivery, and premium craftsmanship.

Customization Options for Neoprene Bags

At Szoneier, we offer complete customization solutions for neoprene bags, including size, color, thickness, logo placement, and advanced printing techniques. From simple logos to full-surface artwork, our customization services help brands create unique, high-quality products for retail, promotions, and private label collections.

Printing Techniques

Color & Pattern

Thickness

Customized Style

Logo Design

Printing Techniques for Neoprene Bags

Our printing solutions for neoprene bags ensure your brand stands out with vibrant colors, sharp details, and long-lasting durability. From cost-effective screen printing to full-surface sublimation, we offer techniques tailored to your design complexity, order volume, and budget—delivering professional results for retail, promotions, and private label collections.

1. Screen Printing

Ideal for simple logos and text, screen printing offers solid colors, sharp edges, and cost efficiency—perfect for high-volume promotional orders and one or two-color designs.

2. Heat Transfer Printing

Using high temperature and pressure, heat transfer printing delivers vivid colors, gradients, and precise details, making it suitable for multi-color artwork and mid-sized batches.

3. Sublimation Printing

For full-surface, photo-quality designs, sublimation printing embeds ink into the fabric layer, ensuring bright colors, all-over coverage, and long-lasting durability.

4. Woven Labels & Patches

Add a premium, retail-ready look with woven labels or logo patches for subtle, long-lasting branding that elevates the overall product quality.

Color Options for Custom Neoprene Bags

We provide versatile color customization for neoprene bags, including standard solid colors and Pantone-matched options for precise brand consistency. Whether for bulk promotions or premium private label projects, our color solutions ensure visual accuracy and fast turnaround for every order.

Solid Color Choices

Pantone Color Matching

Inner–Outer Combos

Pattern Library

Thickness Options for Custom Neoprene Bags

Different neoprene thicknesses deliver different levels of insulation, durability, and structure. At Szoneier, we offer multiple thickness options—perfect for promotions, retail, and premium applications—so you can balance performance, cost, and design flexibility.

2mm Neoprene – Ultra Lightweight

Perfect for high-volume giveaways, lightweight pouches, and cost-sensitive promotions. Easy to fold, pack, and ship while still providing basic insulation and water resistance.

Application Scenario: Promotional tote bags, event giveaways, single-use campaigns.

3mm Neoprene – Standard Choice

The most popular thickness for retail, branding, and versatile applications. Balances durability, structure, and cost-effectiveness for everyday use.

Application Scenario: Lunch bags, tote bags, wine bags, retail merchandise.

5mm Neoprene – Heavy-Duty & Premium

Designed for high-end branding, outdoor gear, and protective carrying cases where superior insulation, shape retention, and durability are critical.

Application Scenario: Travel bags, gym bags, cooler bags, premium gift sets.

Style Variations for Custom Neoprene bags

At Szoneier, we offer a wide range of neoprene bag styles to fit every market need—from promotional giveaways to premium retail collections. Choose from versatile designs tailored for travel, sports, fashion, or corporate branding with full OEM/ODM customization support.

Neoprene Tote Bags

Stylish, lightweight, and perfect for retail or promotional branding. Custom sizes, colors, and printing options available.

Neoprene Lunch Bags

Insulated and durable, ideal for corporate gifts, schools, or outdoor use with full branding support.

Neoprene Wine Bags

Protective, waterproof, and perfect for wineries, events, or premium gift packaging.

Neoprene Laptop & Tablet Bags

Shock-absorbent, water-resistant, and designed for tech accessories or corporate merchandising.

Neoprene Gym & Sports Bags

Durable, water-resistant, and ideal for fitness brands, sports clubs, and lifestyle merchandise.

Neoprene Travel & Beach Bags

Spacious, stylish, and perfect for summer retail, vacation brands, or outdoor promotions.

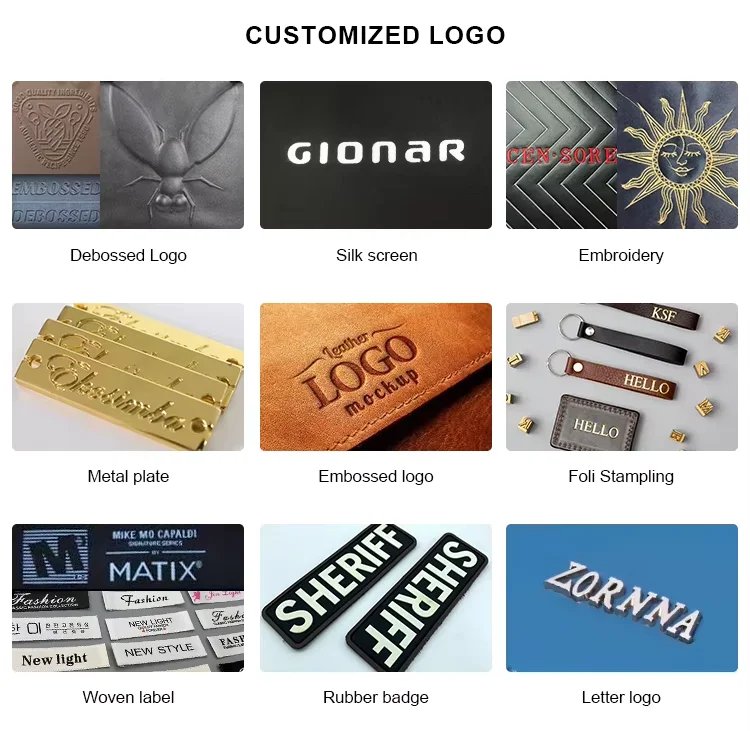

Custom Logo Options for Branding

Szoneier offers multiple logo customization methods for neoprene bags, helping brands achieve professional, durable, and visually appealing results. From direct printing to premium woven labels, we ensure your logo stands out across retail, promotional, and private label collections with consistent quality and precision.

Surface Printing

Apply your logo directly onto the neoprene surface using screen printing, heat transfer, or sublimation for cost-effective branding solutions.

Woven Labels & Hem Tags

Add a premium retail touch with woven labels or hem tags, ideal for lifestyle brands and private label collections.

Rubber / PVC Patches

Durable, weather-resistant patches with 3D embossed logos, perfect for outdoor, sports, and heavy-duty product lines.

Embroidery Patches

Provide a high-end, textured look with stitched patches applied to the fabric surface for premium branding projects.

Make A Sample First?

If you have your own artwork, logo design files, or just an idea, please provide details about your project requirements, including preferred color, and customization options. We’re excited to assist you in bringing your bespoke neoprene Bags designs to life through our sample production process.

OEM/ODM · Development · Processing and Mass Production

Szoneier provides end-to-end OEM/ODM solutions for custom neoprene bags—from concept design and sample development to large-scale manufacturing and global shipping. With 18+ years of expertise, advanced facilities, and strict quality control, we deliver reliable production capacity, low MOQ flexibility, and fast lead times for worldwide buyers.

Concept & Design

- Share your ideas, logos, or sketches—our in-house design team creates free digital mockups and material suggestions to fit your brand vision.

Sample Development

- Rapid prototyping in 3–7 days for size, color, thickness, and logo accuracy. Confirm details before mass production begins.

Bulk Production

- 20+ production lines with automated cutting, printing, and stitching equipment ensure efficiency, consistency, and short lead times.

Quality Control & Shipping

- ISO and OEKO-TEX certified quality systems, 100% inspection before packaging, and fast global shipping via air, sea, or express delivery.

Effective Production Process of Your Neoprene Products OEM

We believe quality is always the key to success, which includes a responsible approach to manufacturing, and controlling whole process.

1-Business Contact

2-Sample Creation

3-Material Preparing

4-Material Cutting

5-Bulk Production

6-Quality Inspection

7-Product Packaging

8-Cargo Warehousing

Promotional Wholesale Neoprene Bags In Stock – Ready To Ship

Szoneier offers factory direct wholesale stock neoprene bag styles with a wide selection of ready-to-ship designs for global buyers. As a leading Chinese manufacturer with over 18 years of experience, we maintain ample inventory of neoprene bags, including lunch bags, tote bags, wine bags, gym bags, and travel bags, ensuring fast order processing and quick delivery for retailers, distributors, and private label brands. All stock neoprene bags are made from high-quality, water-resistant, and durable neoprene materials, providing excellent insulation and customizable options for logos, colors, and packaging. With low MOQ, free design support, rapid sampling, and strict quality control, Szoneier helps small businesses and premium brands reduce lead times and launch products quickly while enjoying competitive factory-direct pricing and consistent quality assurance for every order.

Product Details of Neoprene Bags

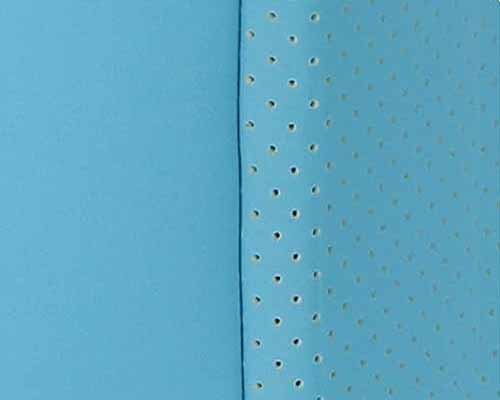

At Szoneier, every neoprene bags is crafted with strict attention to detail. From raw fabric development to precision cutting, lamination, printing, stitching, and packaging, each step is carefully monitored. Our goal is to ensure consistent sizing, strong seams, and durable prints, so every bag performs reliably for promotions, retail, or premium branding projects.

Our neoprene bags are made from high-quality closed-cell neoprene laminated with polyester or nylon fabrics. This combination offers water resistance, insulation, durability, and flexibility for a wide range of applications.

Yes. We provide OEM/ODM customization including logo printing, Pantone color matching, packaging design, and label options. You can choose from silk screen, heat transfer, sublimation, or woven label branding methods.

Our standard MOQ starts from 500 pieces per design, but for certain promotional items or stock colors, we can support low MOQ orders to help small businesses and startups.

Samples can be made in 3–7 days, depending on complexity. Bulk production usually takes 15–30 days after sample approval, with expedited options available for urgent projects.

Yes. Our in-house design team provides free digital mockups, artwork adjustments, and material suggestions before production begins to ensure brand consistency and visual accuracy.

2mm: Lightweight, cost-effective for giveaways.

3mm: Standard thickness for retail and daily use.

5mm: Premium quality for extra insulation and durability.

Yes. Our bags are water-resistant and provide thermal insulation to keep food, beverages, or personal items protected from temperature changes and moisture.

We offer screen printing, heat transfer printing, sublimation printing, and woven labels, ensuring vibrant colors, durability, and a premium look for your branding.

Yes. Our factory operates under ISO9001 quality systems and can provide OEKO-TEX, REACH, and BSCI compliance for materials and manufacturing processes.

We offer bulk packaging, individual polybags, eco-friendly sleeves, hang tags, and custom retail boxes depending on your target market and branding needs.

We support air freight, sea shipping, and express courier delivery worldwide. Trade terms include FOB, CIF, and DDP, with door-to-door service available for certain countries.

Frequently Asked Questions

Welcome to the FAQs on custom neoprene bags, where we answer the most common questions from wholesale and OEM/ODM buyers. Here you’ll find insights on materials, customization options, thickness choices, order quantities, production timelines, and shipping details—helping you make confident, informed decisions for your business.

How do you ensure consistent quality across large orders of neoprene bags?

Ensuring consistent quality across bulk orders is a core priority at Szoneier because international buyers, especially brand owners and distributors, rely on us to maintain uniform standards for every shipment. Our process combines strict raw material selection, advanced production technology, multiple inspection stages, and global certifications to ensure that every neoprene bag meets the same quality benchmark.

We start with raw material control. All neoprene sheets and laminated fabrics are sourced from certified suppliers who provide material safety reports and consistency guarantees. Each batch undergoes thickness measurement, tensile strength testing, and lamination adhesion checks before being released for cutting. We record these parameters in our internal ERP system so they can be traced back for future orders, ensuring repeat production maintains the same quality standards.

Next comes precision cutting and component preparation. We use automated CNC cutting machines with digital templates, eliminating the errors common with manual cutting. This guarantees that each panel of a neoprene bag—front, back, bottom, and handles—matches the exact dimensions specified in the approved sample.

Printing quality is another critical factor. We have dedicated printing lines for screen printing, heat transfer, and sublimation. Before mass printing begins, a pre-production proof (PPS) is approved by the client. During production, our QC team conducts color fastness tests, adhesion tests, and visual inspections under standardized D65 lighting to ensure logo colors match Pantone references and remain consistent across the entire batch.

During stitching and assembly, we maintain SOP manuals for stitch density (typically 8–10 stitches per inch), seam alignment, and thread quality. Each workstation has trained operators supervised by line leaders who perform in-process inspections at set intervals. Bags with even minor defects—uneven seams, loose threads, or printing misalignment—are separated immediately for rework or rejection.

At the final inspection stage, we apply AQL (Acceptable Quality Level) standards, usually 2.5 for major defects and 4.0 for minor defects, which aligns with international export requirements. Random cartons from every batch undergo drop tests, water-resistance tests, and dimensional checks before packaging approval.

We also implement batch numbering systems. Every carton is labeled with production date, batch code, and inspector ID, enabling traceability in case clients request documentation or encounter any issue in their market.

For long-term customers, we retain golden samples—the master reference units—for each product specification. When they reorder months or even years later, production follows the same golden sample, eliminating variation risks.

Finally, our factory holds ISO9001 quality management certification and can provide OEKO-TEX Standard 100 and REACH compliance reports upon request. These certifications prove that our neoprene bags not only meet physical performance standards but also comply with global environmental and safety regulations.

By combining raw material traceability, digital precision cutting, standardized printing, multi-stage inspections, and international certifications, Szoneier ensures that whether a client orders 500 units or 50,000 units, the neoprene bags remain consistent in size, color, performance, and branding quality—building long-term trust with global buyers.

What factors influence the cost of custom neoprene bags for bulk orders?

The cost of custom neoprene bags for bulk orders depends on multiple variables, and understanding these factors helps buyers make budget-optimized decisions without compromising on quality or branding needs. At Szoneier, we offer transparent cost breakdowns so clients know exactly where their money goes.

The first factor is neoprene thickness and material grade. Standard 3mm neoprene is cost-efficient and widely used for lunch bags, wine bags, and promotional totes. Upgrading to 5mm thickness or double-sided laminated fabrics improves insulation and durability but also increases material consumption per unit, raising costs slightly.

Second, bag size and design complexity matter. A simple flat tote bag requires less cutting and stitching than a multi-compartment gym bag with zippers, inner linings, and reinforced handles. More components mean more labor and longer production time, impacting the final price.

Third, custom printing requirements significantly affect cost.

- Screen printing is economical for one or two-color logos in high volumes.

- Heat transfer printing supports multi-color gradients but involves additional film setup fees.

- Sublimation printing offers full-surface, photo-quality designs but requires white fabric bases and longer processing time, making it costlier for small runs.

Fourth, order quantity (MOQ and scaling) plays a big role. Larger orders benefit from economies of scale—material suppliers offer lower prices per square meter, and production lines become more efficient with fewer changeovers. That’s why a 10,000-unit order has a significantly lower per-unit cost than a 500-unit trial run.

Fifth, packaging options influence pricing. Bulk packaging in export cartons costs less, while individual retail packaging—poly bags with barcodes, hang tags, or custom boxes—adds extra materials and labor steps.

Sixth, certification and compliance needs also matter. If a client requires OEKO-TEX certification, REACH compliance, or factory audits like BSCI/SEDEX, the testing fees and audit preparations are factored into overall costs.

Seventh, shipping terms and lead times affect the final landed cost. Air freight ensures speed but costs more than sea shipping. Similarly, rush orders requiring overtime shifts or air transport add premiums compared to standard 30-day production with sea delivery.

Finally, value-added services—like free digital mockups, low MOQ flexibility, or inventory stocking agreements—might slightly influence costs but offer long-term savings by reducing the buyer’s risk and time-to-market.

By balancing material choices, printing methods, packaging options, and order volumes, buyers can work with Szoneier to create cost-effective yet premium-quality neoprene bags tailored to their target market and price positioning.

How do you support OEM/ODM clients from concept to mass production for neoprene bags?

At Szoneier, we specialize in OEM/ODM partnerships, helping brands and distributors bring new neoprene bag ideas to life with end-to-end manufacturing solutions. Our support covers design consultation, prototyping, bulk production, quality assurance, and global logistics, ensuring a smooth journey from concept to final delivery.

The process begins with idea sharing and concept validation. Clients provide sketches, reference samples, or functional requirements—like bag size, intended use (e.g., lunch bag, gym bag), insulation needs, and branding preferences. Our design team translates these inputs into technical drawings and 3D renderings, offering suggestions on material thickness, stitching reinforcements, and printing techniques for both durability and aesthetics.

Next comes material selection and sampling. We help clients choose between 2mm, 3mm, or 5mm neoprene, laminated fabrics, zippers, and accessories. Digital mockups are provided for logo placement and color approval. Then, we produce physical prototypes within 3–7 days, allowing clients to test product performance, fit, and visual appeal before mass production.

Once samples are approved, we create a detailed production plan. This includes raw material procurement, cutting die setup, printing plate preparation (for screen or heat transfer printing), and production line scheduling. Each batch starts with a pre-production sample (PPS) for final confirmation, minimizing risks of errors during large-scale manufacturing.

During bulk production, our 20+ production lines use automated cutting machines for dimensional accuracy, dedicated printing stations for consistent logo quality, and skilled sewing teams for assembly. Real-time QC inspections happen at each stage—printing checks, seam strength testing, and dimensional verifications—ensuring alignment with the approved PPS.

For branding support, we offer custom packaging, woven labels, hang tags, and retail-ready barcoding, so finished products are shelf-ready upon arrival.

Finally, our logistics team coordinates shipping via sea, air, or courier, handling export documentation, customs clearance, and delivery scheduling. Clients can choose FOB, CIF, or DDP terms based on cost and speed requirements.

By integrating design expertise, flexible sampling, mass production capacity, strict quality control, and global logistics, Szoneier enables OEM/ODM clients to launch high-quality, custom neoprene bags quickly, efficiently, and at competitive costs—building long-term partnerships with international brands.