Your Trusted Custom Neoprene Work Gloves Products Manufacturer

We make it easy for you to build your brand by providing a one-stop solution to your OEM/ODM custom production.

We ensure that every custom neoprene work gloves with high quality will stand out

Neoprene work gloves customization in various types,colors,pattern ,logo,and others design is what Oneier Company does best.

We offer OEM neoprene work gloves products in a broad range of types, artwork, packaging and other accessories.

Also, we have a strong fabric supply chain to provide the widest range of fabric customized services for your neoprene work gloves.

Our product has received 100% repurchase from our partners,Strict quality control reflected in product details.

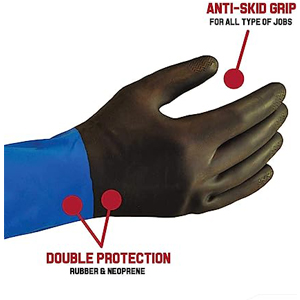

Detail One

Detail Two

Detail Three

Detail Four

Elevate Your Work Experience with Our Customizable Neoprene Work Gloves!

Product Characteristics:

- Premium Neoprene Material: Our work gloves are crafted from top-notch neoprene, a synthetic rubber that offers a superior balance between flexibility and durability. This material is renowned for its resistance to oil, chemicals, and water, making it an ideal choice for various demanding work environments.

- Layered Fabric Technology: The gloves feature a layered fabric technology, incorporating an inner lining that offers comfort and sweat absorption, ensuring a pleasant wearing experience even during long hours of work.

- Enhanced Grip: The gloves are designed with a textured palm surface that ensures a firm grip on tools and machinery, reducing the risk of accidents and enhancing work efficiency.

- Impact and Vibration Reduction: Our gloves are equipped with padded regions that absorb shocks and vibrations, minimizing hand fatigue and preventing injuries.

- Wrist Support: The extended wrist section provides additional support, preventing strain and offering protection against wrist injuries.

- Customized Sizing Solutions: We offer a comprehensive range of sizes, including options for individuals with larger or smaller hands. Our team can work closely with you to develop gloves with customized sizes that cater to your specific market.

- Ergonomic Design: The gloves are designed with an ergonomic approach, offering a natural fit that conforms to the hand’s contours, promoting comfort and reducing strain during prolonged use.

- Multi-Industry Application: These gloves find utility in a plethora of industries including construction, fishing, manufacturing, and more, offering versatile solutions that cater to different work requirements.

- Recreational Use: Beyond work settings, these gloves are also suitable for recreational activities such as gardening, offering protection against thorns, chemicals, and other potential hazards.

- High Visibility Options: We offer gloves with high-visibility options, incorporating reflective elements that enhance safety in low-light conditions.

- Customizable Aesthetics: Our gloves can be customized with a range of aesthetic options, including different colors and patterns, allowing you to create products that align with your brand identity or personal style preferences.

- Innovative Printing Techniques: We employ a range of innovative printing techniques, including embossing, debossing, and digital printing, offering vibrant and durable logo solutions that withstand the test of time.

- Personalized Branding Solutions: Our team can collaborate with you to develop personalized branding solutions, creating unique logos and designs that resonate with your target audience.

Factory Advantages:

- Our factory is equipped to handle orders of varying sizes, offering a low minimum order quantity that facilitates both small and large-scale projects, allowing for a more personalized approach to production.

- With a flexible production setup, we can adapt to diverse production demands, offering solutions that are both efficient and precise.

- Our in-house design team offers complimentary design services, working closely with clients to develop products that meet their specific requirements and aesthetic preferences.

- We prioritize customer satisfaction, offering free samples that allow prospective clients to assess the quality and craftsmanship of our products before committing to a bulk order.

- Our logistics network is optimized to ensure fast deliveries, meeting your timelines without compromising on product quality.

- We adhere to strict quality control protocols, conducting rigorous inspections at every stage of the production process to ensure the highest quality products.

- Our customer service team is available 24/7, ready to assist with any inquiries and provide support throughout the ordering process, ensuring a smooth and hassle-free experience.

Engage with Us for a Collaborative and Innovative Experience!

We invite you to initiate an online consultation with us, where we can further discuss your needs and preferences, guiding you through the process of creating a product that truly meets the demands of your market.

You just choose any types you prefer for your custom neoprene work gloves, and we will take care of the rest.

As a custom neoprene products manufacturer, Oneier has a team of 20+years experienced engineers, designers, sales consultants, and production team who have been engaged in the research and development of different neoprene products. We also have the ability and equipment to conduct advanced testing, production, and packaging. After all, our goal is to make your ideas into a reality.

Other styles of work gloves

The benefits And Value We can Bring To You

Custom

Sample making 1-3 day

Delivery

Fast delivery in 1-10 days helps you to take more share of the market

Quality

No complaints, no minor hassles for your customers, which will make your sales worry-free

Cost

Fully automatic equipment manufacturing process for each customer to save production costs and make it more competitive

Support

Put forward your ideas, we design to production completion, for you to save more intermediate costs

Certification

Qualified by BSCI ,Disney ,ISO9001,SGS

You can totally trust us with all certifications shown below

Certification Guarantee

International standardized certification and recognition, so that our workflow, product quality, and management level maintain a high degree of worldwide consistency, ensuring the safe use of each customer.

After obtaining the certificate, enterprises are able to improve product quality by implementing standards, improving and perfecting management, so that each pipe household is satisfied.

Official certification by third parties, so that products and services are secure and standardized, and every item delivered to the customer is guaranteed.

Hey, don't hesitate to try & feel the FREE SAMPLES before making up your decision

Cooperating Brand Partners Trusted

Your product is produced in reliable factory like our already cooperating international brand partners below:

Effective Production Process of Your Neoprene Products OEM

We believe quality is always the key to success, which includes a responsible approach to manufacturing, and controlling whole process.

1-Business Contact

2-Sample Creation

3-Material Preparing

4-Material Cutting

5-Bulk Production

6-Quality Inspection

7-Product Packaging

8-Cargo Warehousing

What did our happy clients say?

Andrew Jackson

22nd Oct,2021 America

Due to policy reasons, my team and I have analyzed and developed the sales of neoprene koozie. The sales volume increased by 200% last month. It was beyond my expectation. The store staff told me that our this neoprene sleeves always attract the attention of customers. many old customers introduce their friends to come and purchase because of the good quality of our products.It’s true. Awesome, this works better than any other way of advertising. Thank you for providing us with the neoprene can cooler.

Carl Parein

13th Dec,2019 France

Because of the needs of the company’s project development, I selected many suppliers of neoprene koozie for comparative analysis. I was very lucky to find you on Google. I was surprised by the professionalism of your team. From the sharing of product expertise, the introduction of production technology, and the whole service of order production and delivery, the whole project has been well connected. Our products are sold well in the local market. Thank you very much, We will try to maintain cooperation with you all the time

Daniel Garcia

25th May,2010 Australia

I have chosen neoprene koozie as a new project for the company. In the early stages, I analyzed many Chinese suppliers, but only you mentioned,welcome me to visit your factory at any time. I will not hesitate to schedule and purchase a flight to your company’s factory to learn about your company’s products, production processes, and other information. Your reception service is very meticulous,That’s great. Your factory’s professionalism and service have given me confidence in managing my neoprene can coolers project well. thanks

More Things about Neoprene Work Gloves

What Are The Benefits of Neoprene Work Gloves Products?

As an engineer with extensive experience in neoprene work gloves, I can outline several advantages that these gloves typically offer:

- Chemical Resistance:

- Neoprene is highly resistant to a wide range of chemicals, including oils, acids, solvents, and various caustic substances. This makes neoprene gloves ideal for use in laboratories, cleaning, and chemical handling tasks.

- Waterproof Qualities:

- Neoprene is a waterproof material, which makes these gloves suitable for use in wet environments. They can keep workers’ hands dry and comfortable, thereby enhancing grip and efficiency.

- Durability:

- Neoprene material is known for its physical toughness. It resists cuts, punctures, and abrasions, which is beneficial in handling materials or machinery that could damage lesser materials.

- Thermal Insulation:

- Neoprene provides excellent insulation against cold, due to its closed-cell structure. It can maintain flexibility over a range of temperatures, which is essential for workers in refrigerated areas or those who work outdoors in winter conditions.

- Flexibility and Dexterity:

- Despite its durability, neoprene also allows for a good level of dexterity. It can be manufactured in various thicknesses to balance protection and the ability to handle intricate tasks.

- Comfort:

- Neoprene gloves can be designed with a soft, flexible feel that conforms to the hand, reducing hand fatigue during prolonged use.

- Versatility:

- They can be used in various industries including fishing, food processing, petrochemical, and more. They also come in different designs and can be combined with other materials to suit specific work needs.

- Allergic Reaction Consideration:

- Unlike latex, neoprene does not contain natural rubber proteins, which can cause allergic reactions in some individuals, making them a safer choice for those with sensitivities.

- Weather and Ozone Resistance:

- Neoprene has good resistance to weather, ozone, and sun exposure, ensuring a longer lifespan of the glove even when used in harsh outdoor environments.

- Ease of Maintenance:

- Neoprene gloves are relatively easy to clean and maintain, as they can be washed and dried without losing their protective qualities.

Given these advantages, neoprene work gloves are highly regarded in industries where protection from chemicals, temperature extremes, and abrasive conditions is essential. The choice of neoprene gloves can be critical to safety and performance in many work scenarios.

How Long do Neoprene Gloves Last?

The durability of neoprene gloves is influenced by various factors, including the quality of the neoprene, storage conditions, and the frequency and nature of their use. In optimal storage conditions — cool, dark, and dry environments free from ozone and UV light — neoprene gloves can last up to five years without significant degradation. This is due to neoprene’s inherent stability and resistance to many environmental factors that typically degrade synthetic materials.

However, the operational life of neoprene gloves when in use can vary. Frequent exposure to harsh chemicals, extreme temperatures, and mechanical stress can accelerate the deterioration process. To maximize the lifespan of neoprene gloves:

- Avoid exposure to direct sunlight and high temperatures when storing.

- Keep them away from electric motors and other sources of ozone, which can cause neoprene to crack.

- After use, clean them according to the manufacturer’s instructions to remove any contaminants that could degrade the material.

- Inspect them regularly for signs of wear, such as stiffening, tackiness, or brittleness, as well as tears or punctures.

If stored and cared for properly, and regularly inspected for damage, neoprene gloves can be safely used for many years, providing durable and reliable protection even potentially beyond the five-year mark. However, once signs of aging or wear are detected, they should be replaced to ensure the highest level of protection for the user.

Custom Neoprene Work Gloves Types

Neoprene work gloves come in a variety of types, each designed with specific characteristics to suit different industrial needs. Here are some common types and their characteristics based on my experience in the field:

- Chemical-Resistant Neoprene Gloves:

- Characteristics: Made with a pure neoprene or neoprene blend, these gloves are resistant to a broad range of chemicals, including oils, acids, alcohols, and solvents. They are usually thicker to provide better protection and may have a flock or cotton lining for added comfort.

- Neoprene Coated Gloves:

- Characteristics: These have a neoprene coating applied over a different base material such as cotton, nylon, or a knit fabric. They offer good flexibility and dexterity, and are often used for general handling tasks where liquid protection is needed.

- Neoprene Dipped Gloves:

- Characteristics: Dipped neoprene gloves are made by dipping a glove form into neoprene to coat it. This results in a seamless, waterproof layer that’s flexible and has a good grip. They’re lighter than fully made neoprene gloves and are useful for precision tasks.

- Insulated Neoprene Gloves:

- Characteristics: These gloves have an additional insulating layer, such as fleece or thermal linings, making them suitable for cold-weather work or handling cold substances. They combine the waterproof and chemical-resistant properties of neoprene with insulation against the cold.

- Disposable Neoprene Gloves:

- Characteristics: Designed for single use, these gloves provide a protective barrier against chemicals and contamination in laboratory or medical settings. They are thinner for fine task performance and usually come powdered or powder-free.

- Heavy-Duty Neoprene Gloves:

- Characteristics: Built for durability, heavy-duty neoprene gloves are thick, often reinforced in high-wear areas, and are suitable for handling abrasive materials or heavy-duty chemical work.

- Neoprene Gloves with Grip Enhancements:

- Characteristics: These gloves feature textured surfaces or grip patterns to improve handling in wet or oily conditions. They’re beneficial in environments where precision and grip are critical, such as automotive work or parts handling.

- Anti-Vibration Neoprene Gloves:

- Characteristics: Some neoprene gloves incorporate padding or special materials to dampen vibrations, protecting users from the effects of vibration-heavy equipment.

- Cut-Resistant Neoprene Gloves:

- Characteristics: These are engineered with materials like Kevlar or steel mesh in addition to neoprene to provide cut resistance while retaining chemical protection.

- Biodegradable Neoprene Gloves:

- Characteristics: A newer development in the market, these gloves are made from neoprene that has been formulated to break down more quickly in landfills, offering an eco-friendlier option.

Each type of neoprene work glove is designed to meet specific demands in the workplace, and selecting the right one depends on the nature of the job, the chemicals and materials handled, the required level of dexterity, and the environmental conditions. Manufacturers continue to innovate, combining neoprene with other materials and technologies to enhance the performance and protective qualities of work gloves.

Considerations When Buying Neoprene Work Gloves

When purchasing neoprene work gloves, there are several critical considerations to ensure that you select the right type for your specific needs. Drawing from my experience in the production and research of neoprene work gloves, I recommend the following considerations:

Application and Chemical Resistance:

- Determine the specific chemicals or solvents the gloves will be exposed to. Ensure the neoprene blend is resistant to these substances to provide adequate protection.

Glove Thickness:

- Thicker gloves offer better protection and durability but may reduce dexterity. Choose the thickness that balances protection with the need for manual dexterity in your work.

Temperature Resistance:

- Consider whether the gloves need to resist extreme temperatures. Neoprene gloves are good for thermal insulation, but performance varies by design and thickness.

Fit and Comfort:

- Gloves should fit well to allow for extended wear without causing hand fatigue. Look for ergonomic features and the availability of different sizes to accommodate all users.

Grip Requirements:

- If handling slippery or wet items, look for gloves with textured surfaces to improve grip.

Flexibility and Dexterity:

- For intricate tasks, ensure the gloves offer sufficient flexibility. Thinner neoprene or a combination of neoprene with more elastic materials can enhance dexterity.

Durability and Wear Indicators:

- Consider gloves with reinforced areas where abrasion or puncture risks are highest. Some gloves also feature wear indicators to help determine when they should be replaced.

Cuff Style:

- Cuffs can provide additional protection and prevent debris from entering the glove. Determine if you need a tight-fitting cuff or one that can fit over jacket sleeves, for example.

Allergenic Materials:

- Confirm that the gloves are free from latex or other allergens, especially if the gloves will be used by individuals with known sensitivities.

Maintenance and Cleanability:

- Consider how easy the gloves are to clean and maintain. Some may be reusable and others are disposable after a certain amount of use.

Certifications and Standards:

- Ensure the gloves meet the relevant standards for safety and performance, such as those set by ANSI/ISEA, EN ISO, or other regulatory bodies depending on your region.

Brand and Manufacturer Reputation:

- Research the brand and manufacturer for reliability and quality assurance. Look for reviews or case studies that demonstrate their gloves’ performance in conditions similar to those in which you’ll be working.

Environmental Conditions:

- Evaluate the working environment. UV exposure, ozone, and other environmental conditions can affect the longevity and performance of neoprene gloves.

- Cost and Budget:

- Consider your customers’ budget when selecting custom work gloves. Look for manufacturers that offer competitive prices and bulk discounts, so you can provide your customers with quality facial care at an affordable price. At Oneier,we offer high-quality work gloves including Various styles at an affordable price.

15. Bulk Purchasing Options:

- Minimum Order Quantity: Understand the minimum number of units (MOQ 100-200)required to avail bulk pricing.

- Customization in Bulk: Ensure that customization options are still available when purchasing in bulk.

16. Quality Assurance:

- Make sure to purchase Neoprene work gloves from a reputable manufacturer like Oneier that has stringent quality control measures in place. This ensures that the products you are selling meet safety and efficacy standards and will provide your customers with the best results possible.

By thoroughly evaluating these factors, you can select neoprene work gloves that provide the best protection, performance, and value for your specific industrial needs.

What is The Process for Customizing Neoprene Work Gloves

Customizing neoprene work gloves involves several steps, which may vary slightly depending on the manufacturer’s capabilities and the customer’s specific requirements. Here’s an overview of the typical process:

- Requirement Gathering:

- The first step is to understand the client’s specific needs, including the intended use of the gloves, the required level of protection, sizes, and any additional features like grip patterns, linings, or branding.

- Material Selection:

- Based on the requirements, the appropriate type of neoprene, whether a pure form or a blend, is selected. Additional materials for lining, coatings, or reinforcements may also be chosen at this stage.

- Design Specification:

- Detailed glove designs are created, including the shape, thickness, texture, and any additional elements like cuff style or color. CAD software is often used to design the gloves and create prototypes.

- Prototype Development:

- A sample glove is produced using the selected materials and design specifications. This prototype is tested for fit, comfort, functionality, and compliance with any relevant safety standards.

- Client Review and Feedback:

- The prototype is presented to the client for review. Feedback is gathered, and any necessary adjustments are made to the design.

- Tooling and Molds:

- Once the design is finalized, custom molds for the gloves are created if necessary. This step is particularly important for gloves with unique shapes or features.

- Production of Custom Elements:

- If the gloves include custom elements like logos or specific grip patterns, the production of these elements is set up. This might include creating print plates, molds for raised textures, or programming for automated machinery.

- Manufacturing:

- The gloves are manufactured, which typically includes cutting the neoprene material, applying any coatings or additional materials, and assembling the pieces. This may involve a combination of automated processes and skilled manual labor.

- Quality Control:

- During and after production, the gloves undergo quality control checks to ensure they meet the specifications and standards agreed upon. This may include testing for chemical resistance, durability, and other performance metrics.

- Packaging and Branding:

- The gloves are packaged according to the client’s specifications, which may include custom branding, labeling, and instructions for use.

- Delivery:

- The finished gloves are shipped to the client, accompanied by any necessary documentation such as quality certifications or test results.

- Follow-up and Feedback:

- After the gloves have been delivered and used, manufacturers often gather feedback to ensure client satisfaction and to make any notes for future orders or improvements.

This process ensures that the final product is tailored to the client’s specific needs, from the basic functional design to the final touches that represent the client’s brand and intended glove application.

Is Neoprene FDA Approved?

Neoprene, a synthetic rubber, can achieve FDA approval when it is manufactured using ingredients that meet the specific standards and regulations set by the U.S. Food and Drug Administration (FDA). This ensures that the material is safe for applications that involve direct or indirect contact with food.

Compliance with FDA Guidelines: For neoprene to be FDA approved, it must be produced from ingredients that are on the FDA’s list of approved substances. This is crucial as it ensures that the material does not contain any components that could be harmful when in contact with food or beverages.

Color and Appearance: FDA-approved neoprene is generally available in an off-white color. The color is a distinguishing feature that helps in identifying FDA-compliant materials, ensuring that they are easily distinguishable from non-compliant materials.

Intended Use: FDA-approved neoprene is specifically designed for repeated food exposure. This makes it a safe and reliable choice for applications in the food processing industry, where materials are constantly in contact with different food products.

Oil Resistance: One of the key characteristics of FDA-approved neoprene is its excellent resistance to oils. This property is particularly important in food processing and industrial applications where exposure to oils and fats is common. The material’s ability to resist these substances ensures that it maintains its integrity and does not degrade over time, even under constant exposure.

Preference in Food Processing and Industrial Applications: Due to its compliance with FDA standards, as well as its resistance to oils and suitability for repeated food contact, FDA-approved neoprene is a preferred material in the food processing industry. It is also commonly used in various industrial applications where safety and compliance with health standards are paramount.

In summary, neoprene can be FDA approved when produced with specific, FDA-compliant ingredients, ensuring its safety for use in food-related applications. Its excellent oil resistance and suitability for repeated food contact make it a preferred material in both the food processing industry and various industrial contexts.

Most Asked Questions About OEM ODM Custom Work Gloves Product Line

Are you interested in creating a custom neoprene work gloves product but don’t know where to start?

Here are 10 FAQs to help guide you through the process:

- What options are available for customizing the fit and size of neoprene work gloves?

- We offer a range of sizes from XS to XXL and can customize the fit based on the specific hand measurements provided. Our design team can adjust patterns for unique hand shapes to ensure a comfortable and secure fit for all users.

- Can I have my company logo printed or embossed on the gloves?

- Yes, we provide custom branding options including printing, embossing, or stitching your company logo onto the gloves. We’ll need your logo in a high-resolution format to ensure quality reproduction.

- Is it possible to customize the level of chemical resistance in the gloves?

- Absolutely. We can adjust the neoprene formulation and thickness to enhance resistance to specific chemicals. Let us know the chemicals or solvents the gloves will be exposed to, and we’ll tailor the material accordingly.

- Can we request specific colors for our custom neoprene gloves?

- Yes, we can produce gloves in a wide array of colors. We can also match the color as closely as possible to your brand’s palette or provide color options based on the intended use and industry standards.

- What types of grip enhancements can be added to neoprene work gloves?

- We offer several grip enhancement options, including textured surfaces, grip dots, and raised patterns. These can be applied to the palm, fingers, or the entire glove, depending on your needs.

- Are there different cuff styles available for customized neoprene gloves?

- Yes, we can customize cuff styles to suit various applications, including long cuffs for extra protection, knit wrists to prevent debris entry, and adjustable cuffs for a snug fit.

- How do we determine the appropriate thickness for our customized neoprene gloves?

- The thickness is chosen based on the balance between protection and dexterity needed. Our experts will consult with you to understand your application requirements and recommend the optimal thickness.

- Can we customize the insulation properties of neoprene gloves for cold environments?

- Yes, we offer various lining materials, such as fleece or thermal fabrics, to enhance the insulation properties of the gloves for use in cold conditions.

- What is the minimum order quantity (MOQ) for custom neoprene gloves?

- The MOQ can vary depending on the complexity and customization level of the gloves. We strive to be flexible and can discuss options to meet your needs, whether for a small batch or a full-scale production run.

- How long does it take to produce a customized order of neoprene work gloves?

- Production times may vary based on order size and customization details. Generally, it can take anywhere from a few weeks to several months. We’ll provide a timeline estimate once we finalize the design and order details.

Remember, when it comes to customization, clear communication between the buyer and manufacturer is key to ensuring the end product meets all requirements and expectations. Manufacturers like us typically work closely with clients through each step to deliver gloves that are exactly right for their needs.

Start Your Custom Neoprene Products Business Today!

Anna

Sales Manager

Grace

Sales Manager

Julie

Sales Manager

Mike

Sales Manager

Nancy

Sales Manager

We are here for all your business needs and questions.