Neoprene is everywhere—inside laptop sleeves, beverage coolers, wetsuits, resistance bands, medical supports, and even protective covers for electronics. Yet most consumers, and even many product developers, still cannot clearly explain what neoprene actually is. They know it’s flexible, soft, water-resistant, and surprisingly durable—but what exactly is this engineered material made of? Why does it behave differently from EVA, rubber, silicone, or foam? And more importantly, how do brands choose the right neoprene for real-world product development?

Neoprene is a synthetic elastomer made from polymerized chloroprene, engineered into a closed-cell or open-cell foam with excellent insulation, cushioning, flexibility, and water resistance. It is widely used in products such as bags, koozies, wetsuits, gloves, covers, and sports accessories due to its superior durability, comfort, and protective performance.

Understanding neoprene is not just about knowing the chemistry—it’s about understanding how each step of engineering affects your final product: the thickness, density, compression resistance, recovery rate, lamination fabric, and surface finishing. These variables determine whether a neoprene bag feels plush or firm, whether a wetsuit feels warm or flexible, and whether a laptop sleeve truly protects a device from shock.

I still remember visiting a small startup brand founder who brought two neoprene samples to a meeting. Both looked identical. But one compressed too easily and never bounced back—making it unsuitable for a laptop case. The other had optimal density and lamination, giving the premium protective feel they were chasing. That moment convinced them that neoprene is not just a material—it’s engineering in disguise.

Let’s break down everything buyers, designers, and brand owners should know.

What Exactly Is Neoprene and How Is It Classified as a Material?

Neoprene is a synthetic elastomer created by polymerizing chloroprene into a flexible rubber-like material. Classified as a family of engineered elastomers, neoprene is known for its closed-cell or open-cell foam structure, excellent resilience, water resistance, insulation, and durability. It is widely used in bags, wetsuits, sports braces, covers, and industrial protective products thanks to its balanced mechanical strength and comfort-focused physical properties.

Most people recognize neoprene by its feel—springy, warm, protective—but very few can articulate what it fundamentally is. To understand neoprene, you have to start at the molecular level. Chemically, neoprene is poly-chloroprene, a chain of chloroprene monomers linked together through polymerization. This structure gives neoprene its rubber-like elasticity, while chlorine atoms provide resistance to oils, heat, and degradation. Unlike natural rubber, neoprene does not rely on latex proteins, which is why it’s safer for people with latex sensitivities.

Neoprene is classified into two broad material categories: solid neoprene rubber and neoprene foam. Solid neoprene behaves more like industrial rubber—dense, strong, and capable of resisting compression under heavy load. Neoprene foam, on the other hand, introduces microscopic gas bubbles that create the iconic soft, cushiony feel used in consumer products. This foam exists in two forms: closed-cell and open-cell. Closed-cell neoprene traps nitrogen gas inside sealed pockets, making the material buoyant, water-resistant, and thermally insulating—ideal for wetsuits, bags, drink sleeves, and protective covers. Open-cell neoprene, meanwhile, has interconnected pores that allow air and water to pass through more easily, giving it a softer, sponge-like character.

Another important classification is the polymer base itself. Although the term “neoprene” originally referred to pure chloroprene rubber (CR), the market now includes blends such as SCR (SBR + CR) and SBR-only foams. These variations influence cost, flexibility, compression recovery, and long-term durability. Pure CR neoprene sits at the high end of performance—warm, flexible, and resilient—while SBR is more economical but may feel stiffer or degrade faster.

What makes neoprene particularly interesting is how seamlessly it bridges the gap between soft comfort and structural protection. It’s firm enough to absorb impact yet flexible enough to wrap around curved shapes without wrinkling. That duality is the reason you’ll find neoprene in such a wide range of products—from medical braces to fashion bags, from industrial gaskets to car seat covers.

Understanding neoprene’s classification helps brands and designers choose the right type for their product needs—because not all neoprene is created equal, even if it looks the same from the outside.

How Is Neoprene Made? (From Chloroprene Polymerization to Finished Foam Sheets)

Neoprene is made through chloroprene polymerization, where chloroprene monomers link into long polymer chains to form synthetic rubber. This rubber is mixed with foaming agents, heated, and expanded into closed-cell or open-cell foam blocks. The blocks are then cured, sliced into sheets, laminated with fabrics, and processed into final materials used in bags, wetsuits, covers, gloves, and protective products.

Although neoprene feels simple—soft, springy, and comfortable—the engineering that produces this material is surprisingly complex. At its core, neoprene manufacturing is a multi-stage chemical and mechanical process that transforms a liquid monomer into a foam capable of insulation, shock absorption, and stretching without tearing.

Everything begins with chloroprene, a colorless liquid derived from petroleum or acetylene-based chemical processes. Through polymerization, these monomers are linked into long molecular chains, forming a raw synthetic elastomer known as polychloroprene rubber. This step determines much of neoprene’s base performance—including elasticity, heat resistance, and durability.

Once the rubber is formed, manufacturers introduce blowing agents, carbon black, fillers, metal oxides, vulcanizing chemicals, and stabilizers. The exact formulation varies by grade: high-performance CR neoprene requires cleaner and more precise ingredient control, while SBR or blended SCR foams use cost-adjusted formulations suited for mass-market applications. What matters is the balance between flexibility, firmness, density range, and longevity.

The rubber mixture is then placed into large metal molds and exposed to precise heat and pressure. During heating, the blowing agents release nitrogen gas, which becomes trapped inside the material. This is how closed-cell neoprene foam achieves buoyancy, water resistance, and thermal insulation. Manufacturers must manage gas distribution carefully—too much expansion leads to weak foam, while too little results in stiff or overly dense material.

After expansion, the foam blocks undergo vulcanization, a curing process that strengthens the molecular bonds. This step stabilizes the neoprene and locks in its resilience. Once cured, the blocks are cooled and sliced into sheets of varying thickness—commonly ranging from 1 mm to 10 mm for consumer products, though industrial grades may go thicker.

Next comes fabric lamination, an often-overlooked but critical stage. Neoprene is typically laminated with polyester, nylon, jersey, Lycra®, or other textiles to enhance durability, printability, and stretch behavior. The lamination can be single-sided or double-sided, each offering different performance benefits. For example, double-sided polyester jersey is common for bags and sleeves, while nylon or Lycra® is used for wetsuits requiring flexibility and abrasion resistance.

Finally, the neoprene sheets are die-cut, stitched, or molded into final products. For manufacturers producing custom bags, koozies, gloves, or protective covers, the consistency of the foam sheet—density, recovery rate, lamination strength—determines the quality of the final product.

Below is a simplified version of the neoprene production process:

Table: Neoprene Manufacturing Process Overview

| Stage | Description | Key Output |

|---|---|---|

| 1. Polymerization | Chloroprene monomers form polymer chains | Polychloroprene rubber |

| 2. Blending | Add blowing agents, stabilizers, fillers | Foam-ready rubber compound |

| 3. Foaming Expansion | Gas expands under heat in molds | Closed-cell neoprene block |

| 4. Vulcanization | Heat cure strengthens structure | Stable, resilient foam block |

| 5. Slicing | Block cut into sheets of desired thickness | Neoprene foam sheets |

| 6. Lamination | Fabric bonded to foam surfaces | Functional neoprene material |

| 7. Product Conversion | Cutting, sewing, molding | Final neoprene products |

This step-by-step process explains why neoprene materials differ dramatically in feel, density, flexibility, and cost. Even small manufacturing variations—like curing temperature or lamination pressure—can create big differences in performance.

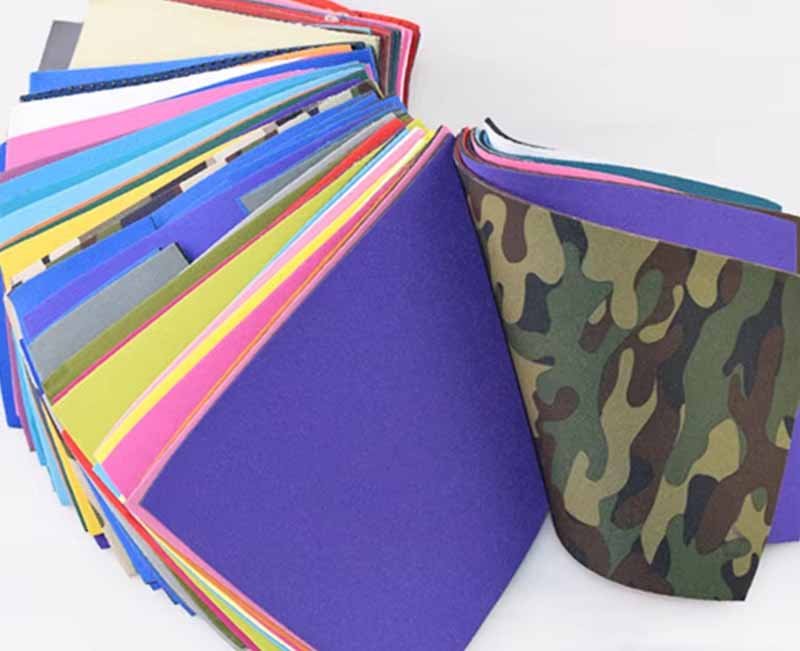

What Types of Neoprene Materials Exist Today? (CR vs SBR vs SCR vs Limestone Neoprene)

The four main types of neoprene are CR (chloroprene rubber), SBR (styrene-butadiene rubber), SCR (a CR–SBR blend), and limestone neoprene. CR offers the highest durability, flexibility, and aging resistance. SBR is more economical but less resilient. SCR blends combine cost efficiency with moderate performance. Limestone neoprene uses calcium carbonate instead of petroleum-based chloroprene, resulting in improved insulation, elasticity, and environmental appeal.

Neoprene is not a single, uniform material. In fact, the global marketplace contains multiple variations engineered for different performance needs and budget levels. What looks like the same “black foam” on the outside can behave completely differently depending on the polymer structure inside. That’s why a premium wetsuit feels buttery soft and warm while a cheap neoprene sleeve feels stiff and loses shape quickly.

1. CR Neoprene (Chloroprene Rubber): The Premium Standard

CR is the original neoprene invented by DuPont. It is still regarded as the highest-performance grade. CR offers exceptional elasticity, insulation, chemical resistance, and long-term durability. It returns to shape quickly after compression, making it ideal for bags, braces, gloves, and wetsuits. High-end sports and outdoor brands almost always choose CR due to its superior comfort and lifespan.

2. SBR Neoprene (Styrene-Butadiene Rubber): The Economical Alternative

SBR is not true neoprene, but many factories blend or substitute it because it reduces cost significantly. SBR is suitable for casual-use items such as promotional koozies, budget sports accessories, and simple protective sleeves. However, it tends to degrade faster, absorb more water, and lose elasticity over time. For low-cost mass programs, SBR is still a practical choice.

3. SCR Neoprene (Blended Foam): The Industry’s Middle Ground

SCR blends CR and SBR together to create a foam that balances cost and performance. Many mid-range wetsuits, fitness accessories, and consumer goods use SCR. It offers better flexibility and resilience than SBR but does not fully match CR’s premium characteristics. For brands needing decent quality at moderate pricing, SCR is a strong contender.

4. Limestone Neoprene: The Modern Eco-Optimized Option

Limestone neoprene replaces petroleum-based chloroprene with calcium carbonate sourced from limestone. This shift alters the molecular structure, resulting in improved stretch, warmth, and water-resistance. Although often marketed as eco-friendly, limestone neoprene still undergoes industrial chemical processing, so “sustainable” claims should be understood realistically. Nonetheless, its performance advantages are tangible, especially in the wetsuit and high-stretch accessories markets.

Comparison Table: CR vs SBR vs SCR vs Limestone

| Property | CR Neoprene | SCR Neoprene | SBR Foam | Limestone Neoprene |

|---|---|---|---|---|

| Durability | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★★★ |

| Flexibility | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★★ |

| Water Resistance | High | Moderate | Low–Medium | Very High |

| Compression Recovery | Excellent | Good | Poor | Excellent |

| Warmth / Insulation | High | Medium | Low | Very High |

| Cost Level | High | Medium | Low | High |

| Typical Use | Wetsuits, gloves, premium bags | Mid-range accessories | Budget sleeves, koozies | High-end wetsuits, stretchwear |

Why This Matters for Buyers

Choosing the wrong neoprene grade can completely alter the feel and longevity of your product. For instance:

- A laptop sleeve in SBR may compress permanently after a few months.

- A wetsuit made of SCR will work for casual use but feel stiff to experienced divers.

- A fitness belt in CR will retain elasticity far longer under repeated stretching.

Understanding materials allows buyers to negotiate better, set correct expectations, and ensure final products match brand positioning.

Which Material Properties Make Neoprene So Popular for Bags, Koozies, Covers, and Wetsuits?

Neoprene is popular because it offers a unique combination of flexibility, insulation, cushioning, water resistance, impact protection, and shape retention. Its closed-cell structure prevents water absorption, while its natural elasticity allows it to stretch and recover without tearing. These properties make neoprene ideal for bags, drink sleeves, wetsuits, electronics covers, sports supports, and protective gear.

Neoprene’s wide adoption across industries is no coincidence—it’s one of the few materials that can deliver comfort, structure, shock absorption, and water resistance in a single package. What makes neoprene exceptional is not one property but the combination of many working together.

1. Flexibility Without Sacrificing Strength

Most foams lose structural integrity as they get softer, but neoprene maintains strength even when stretched. This is why neoprene laptop sleeves can contour to a device while still protecting it, or why a wetsuit can wrap closely around the body without tearing. The internal crosslinked polymer chains allow repeated stretching and bending while still returning to shape.

2. Closed-Cell Water Resistance

Neoprene’s closed-cell structure traps gas bubbles inside sealed pockets. This prevents water from passing through and gives the foam buoyancy—critical for wetsuits and water sports gear. For bags and covers, this closed-cell architecture keeps moisture out and protects items from sudden spills or rain. Even when laminated with fabric, the foam layer remains water-resistant.

3. Natural Thermal Insulation

The nitrogen-filled cells act like tiny thermos chambers, slowing down heat transfer. This is why neoprene helps keep drinks cold, keeps the human body warm in water, and shields electronics from thermal changes. This insulation is a key reason neoprene covers are used for cameras, drones, and outdoor equipment.

4. Superior Impact & Shock Absorption

Neoprene compresses under pressure and then rebounds smoothly, making it ideal for protective cases, gym accessories, braces, pads, and industrial vibration dampening. The foam absorbs energy rather than transmitting it—protecting delicate items like lenses, tablets, and sensors.

5. Shape Retention & Anti-Deformation

Some foams collapse permanently after pressure, but good-quality neoprene (especially CR neoprene) returns to shape repeatedly. This is crucial for products like:

- knee braces

- waist trainers

- fitness belts

- protective sleeves

- structured bags

Shape retention keeps products looking new longer and prevents sagging.

6. Soft, Comfortable, and Skin-Friendly Surface Feel

Unlike EVA or rigid PU foams, neoprene has a plush, breathable feel when laminated with jersey or nylon fabrics. It doesn’t scratch the skin, doesn’t feel “plasticky,” and conforms naturally to body curves. This tactile quality makes neoprene particularly appealing for fashion-forward bags and accessories.

Table: Key Neoprene Properties & Performance Scorecard

| Property | Neoprene Score | Why It Matters |

|---|---|---|

| Flexibility | ★★★★★ | Allows stretching, bending, and shaping without tearing |

| Water Resistance | ★★★★★ | Protects electronics, keeps wetsuits warm, keeps bags dry |

| Thermal Insulation | ★★★★☆ | Maintains body heat or stabilizes item temperature |

| Impact Protection | ★★★★☆ | Absorbs shock for sleeves, cases, and sports accessories |

| Durability | ★★★★☆ | Withstands frequent use, sun, sweat, saltwater |

| Comfort / Softness | ★★★★★ | Feels great on skin and improves user experience |

| Shape Retention | ★★★★☆ | Prevents deformation and extends product lifespan |

Why This Matters to Real Buyers

When you combine all these traits—protection, comfort, insulation, durability—you get a material that works for almost any lifestyle product. Whether you’re designing a premium neoprene tote bag or an industrial protective sleeve, these properties dictate how the final product performs, feels, and ages over time.

This is why neoprene continues to dominate categories like wetsuits, koozies, medical supports, and laptop sleeves—it strikes the perfect balance between performance and comfort.

How Does Neoprene Compare to EVA, TPU, Silicone, and Traditional Rubber?

Neoprene differs from EVA, TPU, silicone, and traditional rubber in flexibility, water resistance, cushioning, insulation, durability, and overall comfort. Neoprene offers superior stretch, insulation, and shock absorption, while EVA is firmer and lighter. TPU is tougher and more abrasion-resistant. Silicone excels in heat resistance. Traditional rubber is stronger but less comfortable. Each material suits different applications depending on performance needs.

Choosing the right material is never as simple as picking “the strongest” or “the softest.” Each material behaves differently in the real world, and understanding these differences is what allows brands to develop better products. Buyers often consider neoprene alongside EVA foam, TPU film, silicone rubber, or traditional natural rubber. While all four materials are widely used, they fill completely different performance roles.

1. Neoprene vs. EVA Foam

EVA is lightweight and rigid compared to neoprene. It excels in firmness, structure, and cost efficiency, making it popular for shoe midsoles, yoga blocks, and hard cases. However, EVA doesn’t offer the same flexibility or comfort. Neoprene, by contrast, conforms to curves, absorbs shock more evenly, and has better thermal properties. If comfort or body contact is important, neoprene almost always wins. If rigidity is required—like a protective hard case—EVA is the better choice.

2. Neoprene vs. TPU (Thermoplastic Polyurethane)

TPU is tough, abrasion-resistant, and highly durable. It’s used in phone cases, outdoor gear reinforcements, and waterproof coatings. However, TPU lacks the soft, cushioned, breathable feel of neoprene. For products needing structure and protection—such as waterproof backpacks—TPU is perfect. For flexible, wearable products—like knee braces or wetsuits—neoprene performs better.

3. Neoprene vs. Silicone

Silicone is extremely heat-resistant and chemically inert, making it ideal for kitchenware, medical-grade items, and industrial seals. Yet silicone is heavier, less flexible in sheet form, and lacks the foam structure needed for shock absorption. Neoprene offers a more comfortable texture and better insulation for wearables. Silicone wins in high-heat environments; neoprene wins in comfort and flexibility.

4. Neoprene vs. Traditional Rubber

Natural rubber is strong, impact-resistant, and ideal for tires, belts, and industrial components. However, it’s heavier, less flexible, and not as user-friendly for consumer products. Neoprene retains many benefits of rubber but adds softness, elasticity, and cushioning, making it more suitable for lifestyle products and apparel. Natural rubber is best for mechanical applications; neoprene is best for comfort-focused designs.

Multi-Material Comparison Matrix

| Property | Neoprene | EVA | TPU | Silicone | Natural Rubber |

|---|---|---|---|---|---|

| Flexibility | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ |

| Cushioning | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ |

| Water Resistance | ★★★★★ | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Thermal Insulation | ★★★★★ | ★★★☆☆ | ★★☆☆☆ | ★☆☆☆☆ | ★★☆☆☆ |

| Durability | ★★★★☆ | ★★★☆☆ | ★★★★★ | ★★★★★ | ★★★★★ |

| Weight | Medium | Light | Medium | Heavy | Heavy |

| Skin Comfort | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ |

| Best Use | Wearables, bags, covers | Hard cases, midsoles | Reinforcements, waterproofing | Medical, kitchenware | Industrial use |

Why This Comparison Matters to Brands

The right material depends heavily on the final product’s goal:

- Best for comfort & softness? Neoprene

- Best for lightweight rigidity? EVA

- Best for abrasion-proof waterproofing? TPU

- Best for extreme heat or medical compliance? Silicone

- Best for mechanical strength? Natural rubber

By understanding these trade-offs, decision-makers can avoid costly mistakes—like choosing EVA for a wearable strap or silicone for a shock-absorbing pouch. Materials are not interchangeable, and choosing the right one directly affects product quality, customer satisfaction, and brand reputation.

Is Neoprene Safe, Eco-Friendly, or Hypoallergenic?

Neoprene is generally safe and hypoallergenic because it contains no natural latex proteins and is stable after curing. Modern neoprene—especially CR and limestone neoprene—meets safety standards such as REACH and RoHS when produced correctly. While not fully eco-friendly due to chemical processing, newer formulations reduce emissions and improve durability, making neoprene safer and longer-lasting than many foams.

Neoprene’s safety is often misunderstood. Some people confuse neoprene with natural rubber latex, assuming it may cause allergic reactions. In reality, neoprene does not contain latex proteins, and its polymer structure is non-reactive after curing. This is why neoprene is widely used in medical braces, orthopedic supports, and wearables that remain in contact with skin for hours.

1. Is Neoprene Safe for Skin Contact?

Yes—properly manufactured neoprene is safe for direct skin contact. The polymer itself is inert, and the foam is typically laminated with nylon or polyester fabric, creating a barrier between the skin and the foam. Low-quality neoprene, however, may contain residual chemicals or poor-quality dyes in the fabric layer. This is where certifications such as REACH, RoHS, and OEKO-TEX come in. High-quality neoprene producers follow strict emission and chemical usage controls, ensuring the final material is clean and stable.

2. Is Neoprene Hypoallergenic?

Most neoprene is considered hypoallergenic. Skin reactions usually stem from:

- dyes in low-grade fabric laminations

- adhesives used during lamination

- extended sweat exposure trapped under a sleeve

Not the neoprene itself. That said, individuals with chemical sensitivities should always test new wearable equipment, regardless of the material.

3. Environmental Impact: Is Neoprene Eco-Friendly?

This topic requires nuance. Traditional neoprene comes from petrochemical-based chloroprene. Its manufacturing process involves energy use and emissions—but so do most industrial materials. The industry has made progress:

- cleaner catalyst systems

- improved emission capture

- reduced solvent use

- limestone-based neoprene alternatives

Limestone neoprene is often marketed as a “green” alternative because the base material (calcium carbonate) replaces petrochemical feedstock. While it does reduce reliance on petroleum, the conversion process still requires significant energy, so calling it 100% eco-friendly would be misleading. However, limestone neoprene usually lasts longer and performs better, indirectly reducing waste.

4. What About Odor or Chemical Smell?

Fresh neoprene sometimes carries a mild “rubber-like” smell due to manufacturing residues. High-end factories remove this through post-curing and ventilation. Low-end SBR foams often smell stronger because of cheap fillers and unstable compounds. This is why sourcing from experienced suppliers is important—quality differences are real and noticeable.

5. Regulations and Global Standards

Modern neoprene frequently complies with:

- REACH (EU)

- RoHS (lead & heavy metal restrictions)

- Prop 65 (California)

- OEKO-TEX Standard 100 (textile safety)

Consumers rarely know what these standards mean, but brands do—and adherence is directly tied to whether a product can legally be sold in certain countries.

Summary: Safety Takeaways for Buyers

- Neoprene is latex-free, safe, and hypoallergenic when manufactured properly.

- Limestone neoprene offers performance and sustainability advantages but is not a miracle eco-solution.

- Poor-quality neoprene (low-grade SBR) may have higher odor and lower safety control.

- Certifications matter—especially for products used by children or directly on the skin.

What Are the Most Common Applications of Neoprene Across Consumer and Industrial Markets?

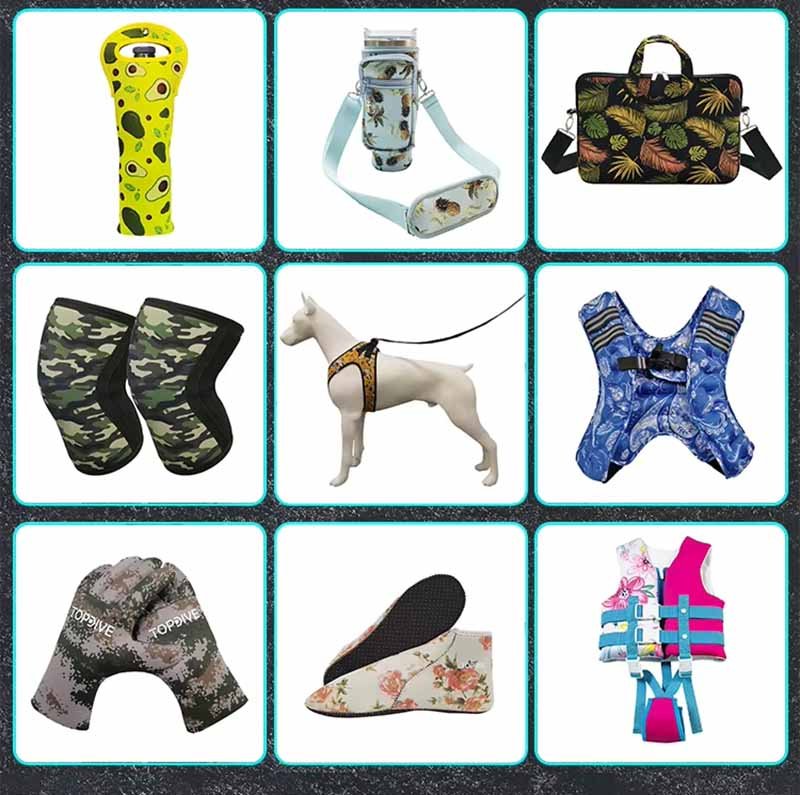

Neoprene is widely used in consumer and industrial products including bags, laptop sleeves, drink koozies, wetsuits, sports braces, gloves, protective covers, medical supports, automotive components, and industrial sealing materials. Its flexibility, insulation, shock absorption, and water resistance make it ideal for wearables, protective gear, and temperature-sensitive applications.

Neoprene is one of those rare materials that quietly fits into almost every part of daily life—without most people ever realizing it. Its high versatility comes from the combination of softness, durability, insulation, compressibility, and comfort, making it suitable for both consumer goods and heavy-duty industrial uses. Let’s break down where neoprene shows up and why it performs so well in each category.

1. Bags, Sleeves & Everyday Accessories

Neoprene has become a staple in modern lifestyle products. Neoprene bags are stylish, lightweight, washable, and resistant to weather. Laptop sleeves made from neoprene cushion devices and adapt to different shapes. Camera covers, tablet sleeves, bottle holders, and travel organizers all benefit from neoprene’s shock absorption and thermal stability.

Real-world example: a neoprene lunch bag keeps food at a more stable temperature than canvas or polyester because of the foam’s insulating cell structure.

2. Water Sports & Outdoor Gear

Wetsuits, swim gloves, snorkeling hoods, surf booties, and paddle-board accessories rely on neoprene’s ability to trap heat and repel water. Few materials can insulate underwater as effectively as neoprene. This is why professional divers depend on CR or limestone neoprene for warmth and flexibility.

Neoprene’s buoyancy also aids swimmers—not by keeping them afloat, but by reducing drag and improving comfort.

3. Sports, Fitness & Medical Supports

Knee braces, waist trainers, wrist wraps, ankle supports, and medical compression devices use neoprene because it warms muscles, stabilizes joints, and delivers gentle compression. Unlike EVA or rubber, neoprene stretches naturally with the body, making it perfect for repetitive movement and long-term wear.

In fitness, neoprene belts help with posture and core stability, while sweat belts use its thermal retention to enhance perspiration.

4. Beverage Cooling & Insulated Holders

Neoprene koozies and bottle sleeves are popular because they keep drinks cold longer and prevent condensation. Polyester koozies can get wet or lose shape, but neoprene maintains its thickness, insulation, and structure even after stretching or squeezing.

5. Electronics & Industrial Protection

Neoprene’s shock-absorbing ability makes it ideal for:

- drone covers

- VR headset sleeves

- camera lens cases

- audio equipment wraps

- GPS and sensor protectors

In industrial settings, neoprene is also used for vibration dampening pads, tool handle grips, anti-slip mats, and sealing components.

Its resistance to oils and chemicals also makes neoprene valuable in automotive gaskets, hoses, and sound-dampening layers.

6. Fashion & Everyday Wear

Neoprene has become popular in fashion because of its structure and smooth aesthetic. Designers use neoprene to create sculptural silhouettes in dresses, skirts, and jackets. The material keeps its shape better than cotton and doesn’t wrinkle easily.

Even sneaker brands use neoprene panels for comfort and flexibility.

7. Pet Products & Specialty Gear

Many dog harnesses, protective vests, pet jackets, and carrier inserts use neoprene to enhance comfort. The foam layer distributes pressure more evenly, preventing skin irritation. Neoprene also stays warm even when wet, a major benefit for outdoor pet gear.

Why Neoprene Works Across So Many Industries

If you look closely at all these applications, a pattern emerges:

Neoprene thrives wherever comfort, protection, flexibility, and insulation intersect.

Most alternative materials only excel in one or two categories. Neoprene excels in five or six simultaneously. That’s why it keeps showing up in new product categories every year—from e-bike accessories to VR fitness gear—because designers know they can rely on its versatility.

How Do Brands Choose the Right Neoprene Material for OEM/ODM Production?

Brands choose the right neoprene by evaluating thickness, density, hardness, stretch, recovery, lamination fabric, surface finish, and intended use. CR neoprene is best for premium products, SCR works for mid-range items, and SBR suits budget programs. The correct combination ensures comfort, durability, and structural integrity in bags, sleeves, wetsuits, medical supports, and accessories.

Choosing neoprene correctly is not simply picking a thickness or color. The “feel,” durability, structure, and performance of the final product come from a combination of foam grade, density, lamination, and finishing processes. Two neoprene sheets may look identical but perform completely differently once sewn into a bag or a wearable accessory.

To help brand teams and sourcing managers make sense of neoprene selection, let’s break it down into the core considerations.

1. Choose Neoprene Thickness Based on Function

Thickness directly affects insulation, protection, rigidity, and comfort. Here’s the general guideline:

Neoprene Thickness Selection Guide

| Thickness | Typical Use | Performance Notes |

|---|---|---|

| 1–2 mm | Fashion bags, apparel panels, gloves | Soft, flexible, low insulation |

| 2–3 mm | Laptop sleeves, tablet covers, medical supports | Balanced protection + flexibility |

| 3–5 mm | Wetsuits, sports belts, protective pads | High insulation, good structure |

| 5–7 mm | Industrial pads, heavy-duty covers | Strong shock absorption, less stretch |

| 7–10 mm | Specialized protective gear | Maximum cushioning and impact resistance |

2. Select Foam Type: CR, SCR, or SBR

- CR neoprene: High-end feel, best recovery, warmest, most durable

- SCR neoprene: Good flexibility with moderate pricing

- SBR neoprene: Economical, good for promotional or lightweight items

A premium brand producing laptop sleeves might choose 3mm CR neoprene, while a promotional koozie supplier may choose 3mm SBR to control cost.

3. Understand Density vs. Hardness (Durometer)

Density affects weight and firmness. Hardness determines how easily the material compresses. Many buyers overlook this—but density often matters more than thickness for protective cases.

Neoprene Density vs Hardness Reference

| Density (kg/m³) | Feel | Ideal Applications |

|---|---|---|

| 80–120 | Very soft | Apparel, wetsuits, flexible gloves |

| 120–150 | Soft–medium | Sleeves, soft bags, medical wraps |

| 150–180 | Medium | Camera bags, sports supports |

| 180–220 | Firm | Protective cases, industrial pads |

Higher density neoprene returns to shape better and compresses less over time.

4. Choose the Right Lamination Fabric

Foam alone is not enough—lamination determines durability, breathability, stretch, printability, and aesthetics.

Common laminations:

| Lamination | Benefits | Common Uses |

|---|---|---|

| Polyester Jersey | Durable, printable | Bags, covers, koozies |

| Nylon Jersey | Strong, smooth, abrasion-resistant | Wetsuits, sportswear |

| Lycra / Spandex | High stretch | Athletic gear, braces |

| Unlined (no fabric) | Maximum softness, cheaper | Industrial pads |

Fabric selection dramatically changes the “feeling” of the final product.

5. Evaluate Stretch, Recovery, and Surface Finish

CR neoprene stretches more consistently, while SBR may feel slightly stiff. Recovery matters in products that experience heavy movement or compression—such as waist trainers, braces, or wetsuits.

Surface finish options include:

- Smooth skin (glides easily, used in wetsuits)

- Sharkskin (grippy texture)

- Embossed patterns (aesthetic or functional)

- Standard jersey (everyday bags and sleeves)

Each one changes the performance and style.

6. Consider Sewing, Bonding, and Construction

Some neoprene grades work better with stitching, while others bond beautifully with heat or adhesive. For example:

- Thin neoprene (<2mm) can wrinkle if stitched improperly.

- High-density neoprene requires stronger needles and reinforced seams.

- Products exposed to water should use blind-stitch or glued seams.

Knowing the material’s behavior allows factories to design more durable products.

7. Match Material to Product Category

Here’s a simple rule of thumb for buyers:

Bags & Sleeves

Choose 2–4mm, medium density, polyester jersey lamination.

Wetsuits & Water Sports Gear

Choose 2–5mm CR or limestone neoprene with nylon/lycra lamination.

Medical & Fitness Supports

Choose 3–7mm medium/high density neoprene with stretch fabric.

Budget Accessories

Choose SBR or SCR to balance cost and performance.

Why This Matters for OEM/ODM Clients

Brands that truly understand neoprene selection can reduce development time, prevent product failures, and negotiate better pricing because they understand what they’re paying for. The right neoprene choice determines:

- how the product feels in the customer’s hands

- how long it lasts

- how well it protects

- how premium the brand appears

Choosing the wrong material guarantees poor reviews and returns.

Conclusion: Why Understanding Neoprene Helps You Build Better Products

Neoprene is one of those rare materials that has managed to stay relevant for nearly a century—not because it’s trendy, but because its performance profile fits the needs of modern life unusually well. From insulation to flexibility, from buoyancy to shock absorption, from comfort to durability, neoprene consistently delivers across categories where other materials fall short.

If you look back through the sections of this guide, a pattern becomes clearer:

- Neoprene is not just foam—it’s engineered elasticity.

- Its structure determines its behavior, and tiny differences matter.

- Choosing the right type (CR, SCR, SBR, limestone) unlocks different performance tiers.

- Thickness, density, lamination, and recovery define product personality.

- Applications span every corner of daily life, from sports to fashion to industrial protection.

Understanding neoprene is not about becoming a chemist. It’s about making smarter decisions as a brand, designer, or sourcing manager. When you know why neoprene works, you also understand when and how to use it strategically. A 3 mm CR neoprene sleeve offers a completely different user experience than a 3 mm SBR sleeve. A limestone neoprene wetsuit feels alive in the water, while a low-density blend feels flat and cold. These differences matter—not just technically, but emotionally, because they shape how customers perceive and trust your product.

Many brands only evaluate neoprene by “price per sheet,” but the real cost is in performance failures: stretched-out bags, flattened foam, poor temperature retention, or wetsuits that lose their warmth within a season. When you choose the correct neoprene from the beginning, you protect your brand reputation, your customer satisfaction, and your long-term product line stability.

At the end of the day, neoprene remains popular not because people understand it, but because it quietly solves problems that few other materials can. And now, with a clearer understanding of what neoprene is and how it behaves, you’re better equipped to design products that truly meet your customers’ expectations—whether that’s warmth, cushioning, comfort, or style.

A Natural, Non-Pushy Invitation

If you’re considering developing custom neoprene products—whether bags, sleeves, koozies, gloves, covers, or wetsuits—it often helps to speak with a manufacturer who works with neoprene every day. neoprene-bag, with more than 18 years of experience in neoprene R&D, lamination, foam engineering, and product manufacturing, supports custom OEM/ODM projects for small and large brands worldwide.

You’re welcome to reach out if you’d like expert material recommendations, thickness guidance, sample reviews, or a quote based on your design. A conversation with a specialized factory often saves weeks of trial and error—and helps ensure the neoprene you choose performs exactly the way your customers expect.