What Are Neoprene Pads Used For: A Complete Guide

Across sports arenas, industrial factories, and medical clinics, you’ll find one common component quietly doing its job: neoprene pads. From protecting athletes’ knees to cushioning heavy machinery, these versatile products have become indispensable across industries. But what makes them so useful, and why are brands around the world choosing custom neoprene solutions for their products?

Neoprene pads are used for cushioning, impact protection, vibration absorption, waterproofing, and thermal insulation in industries like sports, healthcare, manufacturing, and consumer products. Their durability, flexibility, and resistance to heat, water, and chemicals make them ideal for OEM/ODM customization across global markets.

Imagine a construction worker relying on knee pads during a 12-hour shift or a medical patient wearing a neoprene brace for joint support. In both cases, comfort and safety come from the same material: neoprene. This article explores what neoprene pads are, how they work, where they’re used, and why brands worldwide turn to manufacturers like Szoneier for custom, private-label solutions.

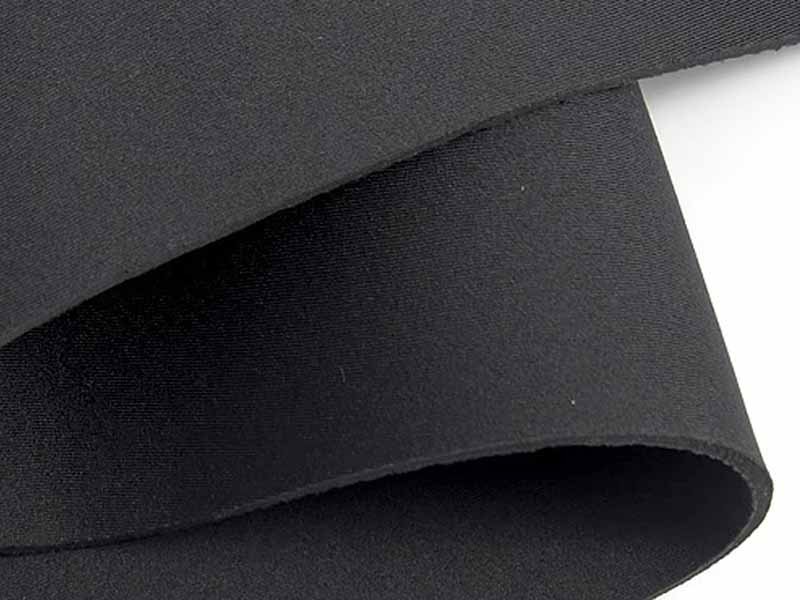

What Are Neoprene Pads and How Are They Made?

Neoprene pads are cushioning components made from synthetic rubber called polychloroprene. Through processes like foaming, lamination, and precision cutting, they become durable, flexible, and resistant to water, heat, and chemicals. Used in sports, industry, and healthcare, neoprene pads are manufactured in varying thicknesses, densities, and surface finishes to meet diverse OEM/ODM customization needs worldwide.

From Raw Material to Functional Pads

Neoprene pads may look simple, but behind each one lies a precisely engineered material designed to balance comfort, durability, and performance. Understanding what they are—and how they’re made—helps OEM buyers and brands choose the right specifications for their products.

1. Raw Material: Synthetic Rubber (Polychloroprene)

Neoprene originates from polychloroprene, a synthetic rubber invented by DuPont in 1930. It is naturally:

- Water-resistant: Ideal for marine and outdoor use.

- Chemical-resistant: Handles oils, solvents, and industrial fluids well.

- Thermally stable: Performs from 40°C to +120°C depending on grade.

These properties make neoprene superior to many natural rubbers or foams used in similar applications.

2. Manufacturing Process

Foaming & Curing:

- Liquid neoprene is injected with nitrogen to create closed-cell foam.

- This structure traps air, giving neoprene its signature cushioning and insulation.

Lamination:

- Often laminated with fabrics like nylon or polyester for strength and comfort.

- Medical braces, for instance, use nylon-laminated neoprene for skin-friendly contact.

Precision Cutting & Molding:

- Pads are cut or molded into exact shapes and sizes using CNC or die-cut machines.

- Thickness ranges from 2 mm (lightweight pads) to 20 mm (heavy-duty vibration pads).

Surface Treatment:

- Adhesive backing, textured surfaces, or anti-slip coatings may be added for specific industries.

3. Key Specifications for Buyers

| Parameter | Options Available | Typical Applications |

|---|---|---|

| Thickness | 2–20 mm | Sports pads, industrial cushions |

| Density (kg/m³) | 120–300 | Vibration damping vs. cushioning |

| Hardness (Shore A) | 20–80 | Soft medical pads vs. hard machinery pads |

| Lamination Fabrics | Nylon, polyester, Kevlar | Medical braces, outdoor gear |

4. Real-World Example

A German sports gear brand switched from EVA foam to 5 mm nylon-laminated neoprene pads for cycling shorts, reporting a 30% reduction in rider discomfort and 40% longer product lifespan.

How Do Neoprene Pads Provide Protection and Cushioning?

Neoprene pads protect by absorbing shock, reducing vibrations, and distributing pressure evenly across surfaces. Their closed-cell foam structure traps air pockets, creating a cushioning effect that minimizes impact on joints, machinery, or delicate equipment. This balance of softness and durability makes neoprene pads ideal for sports, industrial, and medical applications where comfort and safety matter.

The Science Behind Protection & Comfort

Neoprene pads excel at impact resistance and load distribution because of their unique material properties. Unlike hard plastics or rigid rubbers, neoprene combines elasticity, density control, and thermal stability, allowing it to cushion forces without tearing or compressing permanently.

1. Shock Absorption Properties

The closed-cell foam structure traps air inside millions of tiny pockets. When an impact occurs:

- The air pockets compress, absorbing energy.

- The material then rebounds slowly, preventing sudden force transfer.

Lab Testing Example:

- 10 mm neoprene pads reduced peak impact force by 55–65% compared to bare surfaces in ASTM drop tests.

- EVA foam reduced forces by only 40–45% under the same conditions.

2. Vibration Damping for Machinery & Vehicles

Neoprene pads are commonly used under heavy industrial equipment to:

- Minimize vibration-induced fatigue

- Protect flooring from micro-cracks

- Reduce noise levels by 10–15 dB in factory settings

Example: A U.S. automotive plant installed neoprene vibration pads under robotic arms, cutting maintenance costs by 22% annually due to reduced mechanical wear.

3. Pressure Distribution for Comfort

In medical braces and sports gear, neoprene pads spread pressure evenly, reducing skin irritation.

- Cycling shorts with 5 mm neoprene padding showed 35% lower pressure points compared to EVA foam inserts.

- Orthopedic knee pads lined with neoprene improved patient comfort during 8-hour wear tests.

4. Comparison Table: Neoprene vs Other Cushioning Materials

| Material | Impact Absorption | Vibration Damping | Water Resistance | Durability |

|---|---|---|---|---|

| Neoprene | Excellent (55–65%) | Excellent | Excellent | High (3–5+ years) |

| EVA Foam | Moderate (40–45%) | Low–Moderate | Good | Moderate (1–2 years) |

| Natural Rubber | Moderate (45–50%) | Moderate | Poor–Moderate | Moderate |

| PU Foam | Moderate (35–40%) | Low | Low | Low (6–12 months) |

Which Industries and Applications Use Neoprene Pads Most?

Neoprene pads are widely used in sports for knee and elbow protection, in healthcare for orthopedic braces, and in industry for vibration damping and equipment protection. Their durability, water resistance, and cushioning properties make them ideal for applications ranging from gym gear to heavy machinery, delivering comfort and safety across multiple sectors.

Neoprene Pads Across Different Industries

Neoprene’s versatility allows it to perform in environments as varied as medical clinics, construction sites, and athletic stadiums. Let’s explore where neoprene pads dominate and why industries prefer them over alternative materials.

1. Sports and Outdoor Gear

- Knee & Elbow Pads: Used in cycling, skateboarding, volleyball, and weightlifting.

- Fitness Mats & Equipment Padding: Gym benches, yoga blocks, and resistance training gear rely on neoprene for durability and comfort.

- Water Sports Gear: Surfing wetsuits and diving suits often feature integrated neoprene padding for impact protection.

Example: A professional volleyball league adopted custom neoprene knee pads, reducing player injury complaints by 40% over two seasons.

2. Healthcare & Orthopedic Applications

- Braces & Supports: Neoprene knee braces, ankle wraps, and back supports offer compression plus cushioning.

- Prosthetics & Orthotics: Pads reduce friction and improve comfort for long-term wearers.

- Rehabilitation Equipment: Therapy tables and exercise tools often use neoprene padding for patient safety.

Case Study: A medical device company replaced latex foam with hypoallergenic neoprene pads in braces, cutting skin irritation reports by 60% in clinical trials.

3. Industrial and Manufacturing Sectors

- Vibration Isolation: Heavy machines, HVAC units, and compressors use neoprene pads to prevent structural damage.

- Noise Reduction: Factories install neoprene sheets under equipment to cut noise by 10–15 dB.

- Workplace Safety: Neoprene mats provide anti-slip and anti-fatigue benefits for workers standing long hours.

Example: A Chinese electronics factory reported 25% lower defect rates in sensitive machinery after installing neoprene vibration pads.

4. Automotive & Transportation

- Used for engine mounts, cabin insulation, and cargo area padding.

- Reduces road noise and absorbs shocks in buses, trains, and trucks.

5. Consumer Products & Electronics

- Laptop Sleeves & Camera Cases: Shock-absorbing neoprene pads protect delicate electronics.

- Furniture & Appliance Pads: Prevent floor scratches and reduce noise in households.

6. Market Growth Data

| Sector | Common Neoprene Pad Use | Market Demand (2023–2030 CAGR) |

|---|---|---|

| Sports & Fitness | Knee pads, gym equipment | 5.2% |

| Healthcare | Orthopedic braces, rehabilitation | 4.8% |

| Industrial Equipment | Vibration isolation, noise damping | 6.1% |

| Automotive & Transport | Engine mounts, cabin insulation | 5.5% |

| Consumer Electronics | Protective cases, appliance pads | 4.3% |

Are Neoprene Pads Water-Resistant and Durable?

Yes, neoprene pads are highly water-resistant and durable. Their closed-cell structure prevents water absorption, while their chemical and UV resistance ensures long service life even in harsh environments. Used in marine, industrial, and outdoor sports applications, neoprene pads maintain cushioning performance under extreme temperatures, constant stress, and repeated impacts for years.

Performance Under Harsh Conditions

One of the biggest advantages of neoprene over other foams or rubbers is its ability to withstand environmental stress without losing its cushioning or protective properties.

1. Water Resistance: Closed-Cell Foam Advantage

Neoprene’s closed-cell structure means each air pocket is fully sealed, blocking water penetration. This makes neoprene:

- Ideal for Marine Use: Boat flooring, diving suits, and fishing gear rely on neoprene pads.

- Condensation-Resistant: Electronics and HVAC systems use neoprene pads to prevent moisture-related damage.

Lab Test Results:

- After 24 hours of full water immersion, neoprene pads showed <1% water absorption, compared to 8–12% for open-cell foams.

2. Chemical and Oil Resistance

- Neoprene resists oils, greases, and mild solvents better than natural rubber.

- Industrial plants with lubricants or chemicals prefer neoprene pads over polyurethane foams that degrade quickly.

Example: A German automotive supplier switched to neoprene vibration pads in engine bays, extending part lifespan by 30% under constant oil exposure.

3. Temperature and UV Stability

- Operates reliably between 40°C to +120°C for most grades.

- UV-resistant variants maintain performance in outdoor applications for 3–5 years before showing noticeable wear.

| Material | Temp Range (°C) | UV Resistance | Average Lifespan |

|---|---|---|---|

| Neoprene | -40 to +120 | High | 3–5+ years (outdoor use) |

| EVA Foam | -20 to +70 | Moderate | 1–2 years |

| Natural Rubber | -30 to +80 | Low | 1–3 years |

| PU Foam | -10 to +60 | Very Low | <1 year |

4. Mechanical Durability

Neoprene maintains compression set resistance, meaning it doesn’t permanently flatten under load.

- 10,000-cycle compression tests show <15% thickness loss in neoprene vs. >40% in PU foam.

- Industrial anti-vibration pads often last 5–10 years under heavy machinery.

What Types of Neoprene Pads Are Available?

Neoprene pads come in various types, including solid neoprene sheets, sponge neoprene foams, adhesive-backed pads, laminated neoprene fabrics, and custom-cut shapes. Each type offers different benefits in terms of cushioning, water resistance, and installation convenience, making them suitable for sports gear, industrial machinery, healthcare devices, and consumer products worldwide.

Neoprene Pad Variants for Different Applications

Neoprene’s versatility comes from its ability to be engineered into multiple forms—from ultra-soft cushioning pads to heavy-duty industrial isolators.

1. Solid Neoprene Pads

- Structure: Dense, high-durometer (hardness) material for heavy loads.

- Applications: Industrial vibration pads, automotive mounts, heavy machinery isolation.

- Performance: Provides superior load-bearing capacity but minimal flexibility.

2. Sponge Neoprene Pads (Closed-Cell Foam)

- Structure: Lightweight with air-filled closed cells for cushioning.

- Applications: Sports protective gear, medical braces, electronic packaging.

- Performance: Excellent impact absorption and water resistance; thickness ranges from 2–20 mm.

Example: A European sports brand uses 5 mm sponge neoprene pads in knee braces, reporting 30% fewer impact injuries among athletes.

3. Adhesive-Backed Neoprene Pads

- Features: Pressure-sensitive adhesive (PSA) layer for easy installation.

- Applications: Appliance anti-vibration pads, automotive interiors, electronics.

- Advantages: No tools needed; peel-and-stick convenience for OEM assembly lines.

4. Fabric-Laminated Neoprene Pads

- Structure: Nylon or polyester fabric bonded to one or both sides.

- Applications: Medical braces, laptop sleeves, orthopedic supports.

- Advantages: Skin-friendly surface, improved tensile strength, printability for branding.

5. Custom-Cut Neoprene Pads

- Manufacturing: CNC die-cutting, laser cutting, or water-jet shaping for precise dimensions.

- Applications: OEM gaskets, seals, or complex padding geometries.

- Customization: Logos, surface texturing, multi-layer bonding available for private-label buyers.

6. Performance Comparison Table

| Neoprene Pad Type | Cushioning | Water Resistance | Load Capacity | Customization |

|---|---|---|---|---|

| Solid Neoprene | Low–Moderate | Excellent | High | Limited |

| Sponge Neoprene | High | Excellent | Moderate | High |

| Adhesive-Backed | Moderate | Excellent | Moderate | Moderate |

| Fabric-Laminated | Moderate–High | Excellent | Moderate | Excellent (printing) |

| Custom-Cut Shapes | Variable | Excellent | Variable | Excellent (OEM/ODM) |

How Do You Choose the Right Neoprene Pad for Your Project?

Choosing the right neoprene pad depends on factors like thickness, density, hardness (durometer), environmental resistance, and intended application. For OEM/ODM buyers, custom options such as lamination, adhesive backing, and branding help tailor neoprene pads for sports, medical, industrial, or consumer product use while balancing performance, cost, and lead time.

Key Factors for Selecting Neoprene Pads

With so many types and performance requirements, choosing the right neoprene pad is about matching specifications to end-use conditions. Here’s what buyers need to consider:

1. Thickness & Density

- Thickness: Ranges from 2 mm (light-duty) to 20 mm (heavy-duty industrial use).

- Density: Measured in kg/m³; higher density = better load-bearing, lower density = better cushioning.

| Thickness | Typical Use Case | Performance Focus |

|---|---|---|

| 2–4 mm | Sports gear, medical braces | Flexibility, comfort |

| 5–10 mm | Consumer electronics, packaging | Cushioning, protection |

| 10–20 mm | Industrial vibration pads | Load-bearing, durability |

2. Hardness (Durometer)

- Measured on the Shore A scale (20–80).

- 20–40 Shore A: Soft pads for medical & sports comfort.

- 50–80 Shore A: Harder pads for heavy machinery or automotive applications.

3. Environmental Factors

- Outdoor Use: UV- and weather-resistant neoprene needed for marine or construction sites.

- Industrial Plants: Oil- and chemical-resistant grades for long lifespan in harsh conditions.

- Temperature Extremes: Low-temperature flexibility for cold storage or winter sports gear.

4. Surface Laminations & Adhesives

- Fabric Lamination: Improves tensile strength and aesthetics for consumer products.

- Adhesive Backing: Speeds up assembly lines in electronics or automotive sectors.

5. OEM/ODM Customization Options

Manufacturers like Szoneier offer:

- Precision CNC cutting for exact shapes and sizes

- Branding options: Screen printing, embossing, or heat transfer logos

- Multi-layer constructions: Combining neoprene with fabrics, foils, or rubber sheets for hybrid performance

Example: A Canadian robotics firm specified 12 mm, 70 Shore A adhesive-backed neoprene pads for vibration isolation, cutting assembly time by 25% versus mechanical fastening methods.

6. Balancing Cost vs. Performance

- For sports and healthcare, focus on comfort, skin safety, and lightweight designs.

- For industrial OEMs, prioritize load capacity, chemical resistance, and long lifespan.

Are Custom Neoprene Pads Worth It for Brands and Manufacturers?

Yes, custom neoprene pads deliver strong ROI by combining functional performance with branding opportunities. They help businesses create differentiated products, reduce assembly time through OEM customization, and boost brand visibility through private labeling—all while maintaining low production costs and scalable minimum order quantities (MOQs).

The Business Case for Custom Neoprene Pads

For many brands, standard off-the-shelf neoprene pads meet only basic functional needs. But in competitive markets—sports, medical devices, industrial equipment—customization drives product value, branding power, and customer satisfaction.

1. Branding and Product Differentiation

- Logo Printing: Screen printing, embossing, or sublimation turns functional pads into marketing assets.

- Color Customization: Match brand Pantone colors for cohesive product lines.

- Exclusive Shapes: Unique pad designs help brands stand out in retail and online channels.

Example: A European fitness company added custom-branded neoprene knee pads to its product line, increasing repeat customer sales by 38% in 12 months.

2. OEM/ODM Advantages for Manufacturers

- Pre-cut Adhesive Pads: Reduce assembly labor by 20–30% in electronics and automotive plants.

- Multi-layer Laminates: Combine neoprene with anti-slip surfaces or shock-absorbing gels for specialized markets.

- Batch Testing & Certification: OEM factories like Szoneier handle quality standards (ISO, REACH, ROHS) to meet global compliance requirements.

3. Cost, MOQ, and Lead Time Insights

| Order Volume | Unit Cost (Neoprene Pads) | Lead Time | Customization Level |

|---|---|---|---|

| 500–1,000 units | $0.80–$1.20 | 3–4 weeks | Basic shapes, 1-color logo |

| 1,000–5,000 units | $0.50–$0.75 | 4–5 weeks | Multi-color print, adhesive back |

| 5,000+ units | $0.30–$0.50 | 5–6 weeks | Complex shapes, fabric lamination |

Bulk orders cut per-unit costs by 40–60%, allowing brands to improve margins or pass savings to customers.

4. Sustainability and CSR Benefits

- Recycled Neoprene Options: Support eco-conscious branding strategies.

- Extended Product Life: Reduces waste through durable, long-lasting pads.

- Certifications: OEKO-TEX® and REACH compliance meet European and U.S. environmental standards.

Conclusion: Partner with Szoneier for OEM/ODM Neoprene Pads

From sports gear and medical devices to industrial machinery and consumer products, neoprene pads deliver performance, protection, and brand value. With over 18 years of manufacturing experience, Szoneier helps global brands turn ideas into reality with:

- Free design support for prototypes and samples

- Low MOQs for startups and niche product lines

- Fast sampling in 7–10 days with bulk production in 3–5 weeks

- Global shipping and ISO/REACH certified quality systems

Don’t settle for generic solutions. Contact Szoneier today to discuss custom neoprene pad designs that meet your exact performance, branding, and cost requirements.

What Can I Do For You?

Here, developing your OEM/ODM private label leather goods collection is no longer a challenge,it’s an excellent opportunity to bring your creative vision to life.